Electromechanical Diaphragm Pumps are energy-efficient pumps that are suitable for applications in the low pressure range up to 0.8 MPa. They offer a constant flow rate and variable control options, making them ideal for a wide range of media and various industries.

Electromechanical Diaphragm Pumps

Technical Data & Characteristics:

- Delivery rate: 0.1 m³/h up to 40 m³/h (up to 176 gpm)

- Delivery head: up to 60 m (196.85 ft)

- Pressure: up to 6 bar (only für filter press feed up to 8 bar)

- Temperature: 0 °C to +60 °C (+32 °F to +140 °F)

- Viscosity: 0.1 to 5,000 mPa·s

- Solids: up to 65 % (max. 15 mm)

- pH-value: 0 – 15

- Submersibility: none

- self-priming possible

- no mechanical seals

- ATEX: suitable for ExZones 1, 2, 21, 22

- int. Standards: acc. ISO, EN

- Materials Casing: nodular cast iron (NCI), polypropylene (PP), stainless steel (SS)

- Materials Diaphragms: EPDM, NBR, FPM, PTFE, SBR

- Drive: electric

The electromechanical diaphragm pump uses a mechanical linear drive powered by an electric motor. This drive moves the diaphragm back and forth in a smooth, linear motion, which enables precise and controlled pumping. During the suction stroke of the diaphragm, a vacuum is created which opens the inlet valve and draws the medium into the chamber. During the pressure stroke, the medium is pressurized, the inlet valve closes and the outlet valve opens, pumping the medium out of the chamber. The inlet and outlet valves control the flow of the medium and ensure an efficient pumping process. The fact that only the diaphragms, valve balls and valve seats are in contact with the pumped medium minimizes wear. The pumps are also safe to run dry.

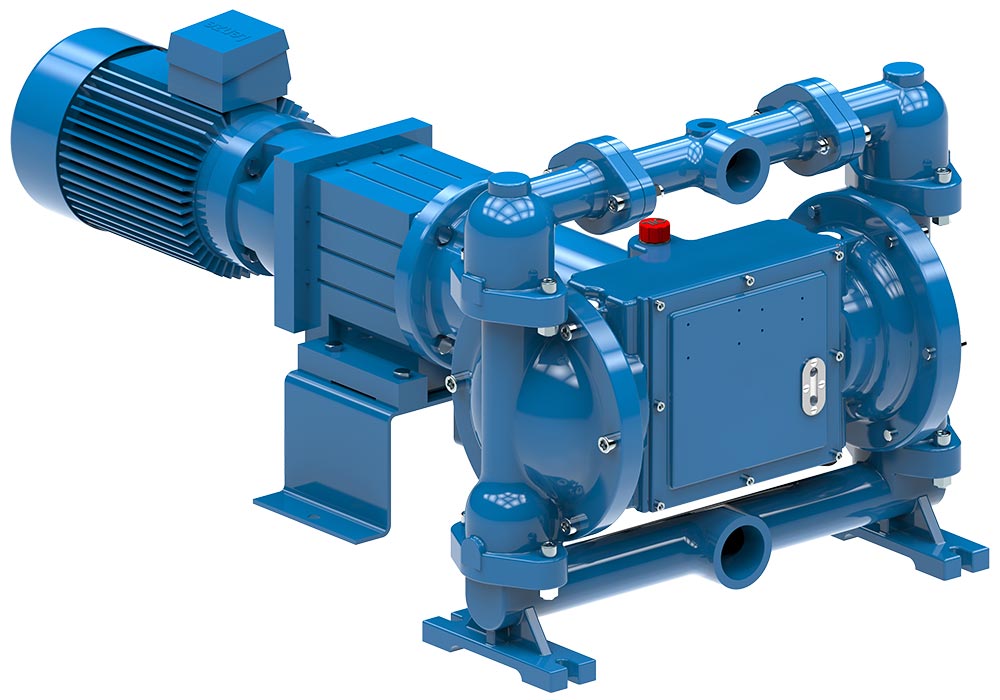

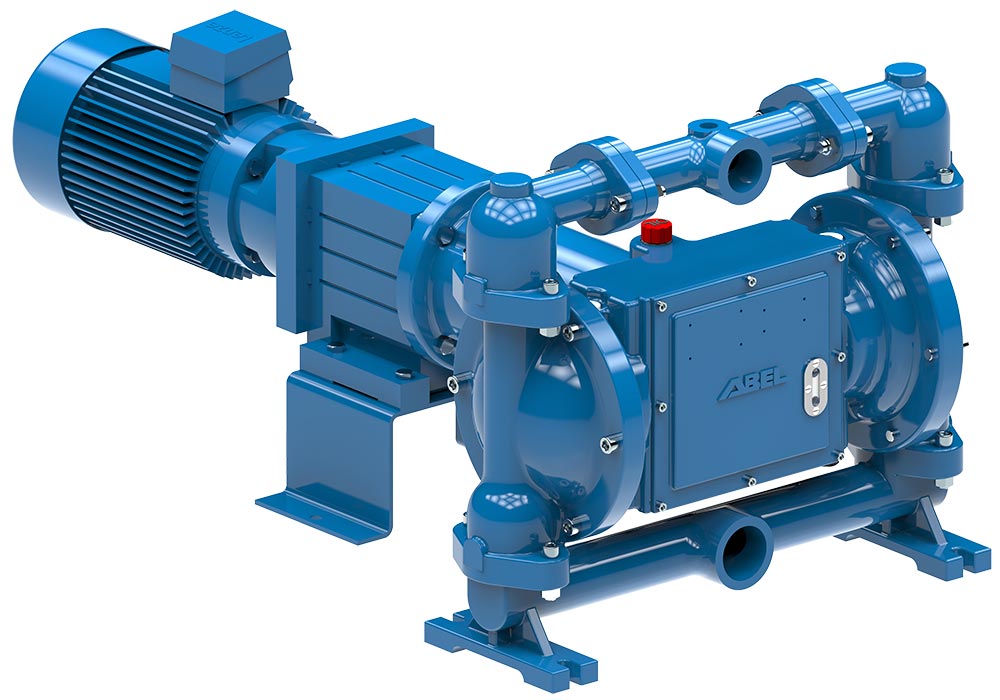

Electromechanical Diaphragm Pump in Metal:

The metal version is particularly robust and durable, ideal for applications with high mechanical loads. It offers high resistance to abrasion and corrosion, making it suitable for demanding environments. It is also versatile and can pump a wide range of media, including abrasive and viscous liquids.

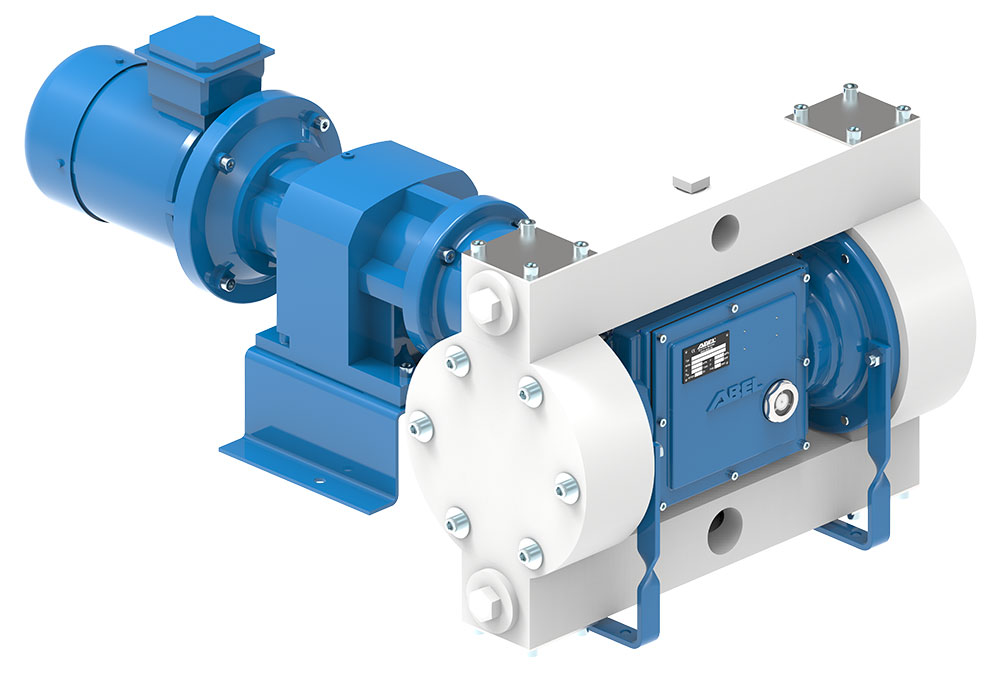

Electromechanical Diaphragm Pump in Plastic:

The plastic version is specially designed for handling aggressive media. High-quality plastics such as polypropylene (PP) ensure high chemical resistance. This version is ideal for applications in the chemical industry and other areas of process technology where aggressive chemicals need to be pumped.

Electromechanical Diaphragm Pumps (EM) are extremely energy-efficient as they do not require compressed air or hydraulic fluid and can reduce energy consumption by up to 80% compared to compressed air pumps. They are safe to run dry, which increases operational safety and minimizes wear. These pumps ensure gentle pumping, ideal for sensitive media. They are versatile, as they can pump abrasive, corrosive, viscous and granular media.

EM pumps are available in different materials such as metal and plastic, making them suitable for a wide range of applications. By dispensing with compressed air, the operating costs are considerably lower compared to pneumatic pumps. The metal versions in particular are characterized by their robustness and durability, which makes them ideal for demanding applications. Electromechanical diaphragm pumps also offer a stable delivery characteristic. The flow rate is therefore independent of the back pressure, which distinguishes them from other pump types.

- Waste water treatment: Used in municipal and industrial waste water treatment plants for conveying sludge with fibrous components.

- Chemical industry: Ideal for transporting corrosive and abrasive chemicals due to its resistance to aggressive media.

- Ceramics industry: Suitable for conveying ceramic bodies and other viscous media.

- Paper manufacturing: Used for conveying fillers and glue

- General process technology: Versatile use in various processes for conveying abrasive, corrosive, viscous and granular media.

The electromechanical diaphragm pump is the reliable and cost-effective solution for small output ranges in various industrial applications. You can easily request here: