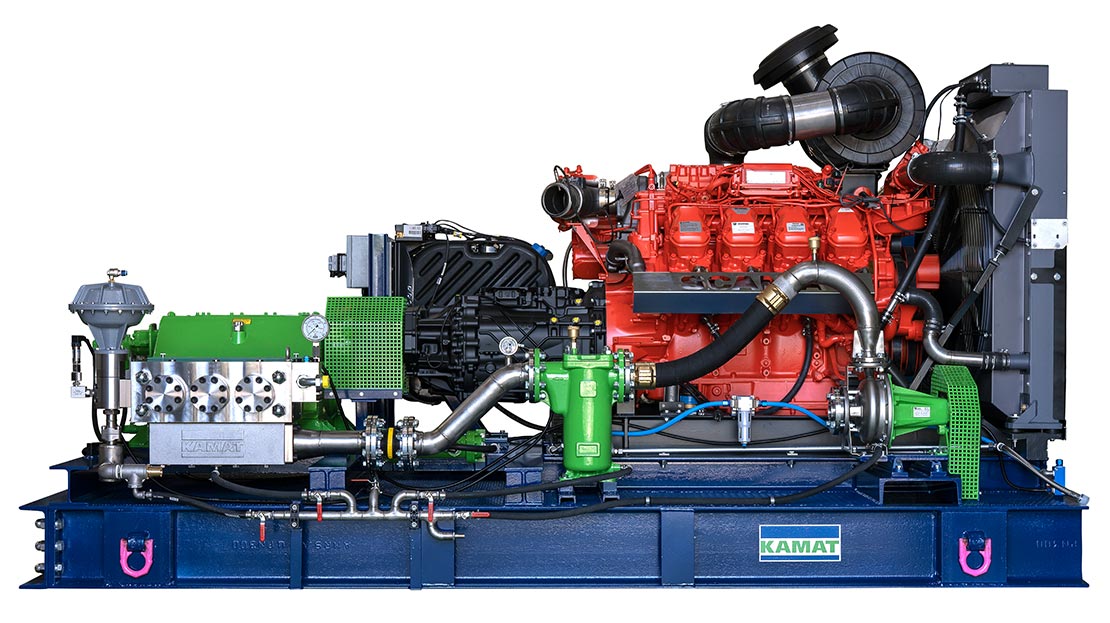

KAMJET 450 Ca – fully automated high-pressure unit with intelligent control, engineered for demanding industrial cleaning applications.

Automation under high pressure: KAMJET 450 Ca

The KAMJET 450 Ca sets the standard for intelligent cleaning systems

Automation is becoming increasingly important in industrial high-pressure cleaning. With the KAMJET 450 Ca, KAMAT presents an intelligent high-pressure system that not only delivers performance, but also thinks ahead – efficiently, safely and reliably.

Fully automatic control for maximum reliability

The heart of the KAMJET 450 Ca is not only the powerful K45000-3G plunger pump – it is the highly developed KAMAT 2025 control system that turns the unit into a networked cleaning solution. It regulates pressure and flow in real time and reacts dynamically to changing process conditions – fully automatically.

The technological highlights at a glance:

- Intelligent pressure and flow control: Automatic adjustment to actual demand reduces energy consumption and mechanical wear.

- Variable motor control: The drive always operates at the optimum load point for maximum efficiency and up to 30% diesel savings.

- Predictive maintenance: Built-in sensors monitor oil level, temperature, pressure and flow. Faults are detected at an early stage, minimising downtime.

- Cleaning profiles at the touch of a button: Repeatable results thanks to storable process parameters – ideal for frequently changing applications.

- Industry 4.0 ready: Remote diagnostics, trend analysis, online monitoring – the control system can be seamlessly integrated into existing process control systems.

- High safety: Automatic emergency shutdown, pressure relief and configurable limits provide reliable protection for the operator and the system.

Modular and easy to service – even under extreme conditions

With a control range of 1:10, the unit can handle a wide range of cleaning requirements – with viscosities up to 2000 mPas and media temperatures up to 200°C. The robust system design is based on the proven KAMAT modular principle. All components are easily accessible – no lifting equipment or special tools required.

Made in Germany – for an automated future

Like all KAMAT products, the KAMJET 450 Ca is manufactured entirely in Germany, including local castings and forgings. The combination of intelligent control, robust machine construction and sustainable energy efficiency makes it the ideal solution for automated high-pressure applications worldwide.

Applications include

- Automated tank, pipe and surface cleaning

- Large plant cleaning with fixed cleaning profiles

- High pressure cleaning in hazardous areas (ATEX option)

- Robotic cleaning systems in 24/7 operation

The KAMJET 450 Ca represents a new generation of automated high-pressure cleaning systems – powerful, networked and future-proof. A clear statement for modern industrial processes that intelligently combine efficiency, safety and sustainability.

Don't hesitate and contact KAMAT now without obligation!

For further information please visit

👉 www.kamat.de

👉 KAMJET Brochure

👉 Member profile at Star Pump Alliance

Source & Pictures: KAMAT