ipp Pump Products GmbH announces the expansion of their product range with the Aqueous centrifugal pump. In addition to their proven premium rotary lobe pumps, ipp Premiumlobe and ipp iLobe, they now also offer a first-class solution for pumping low-viscosity media.

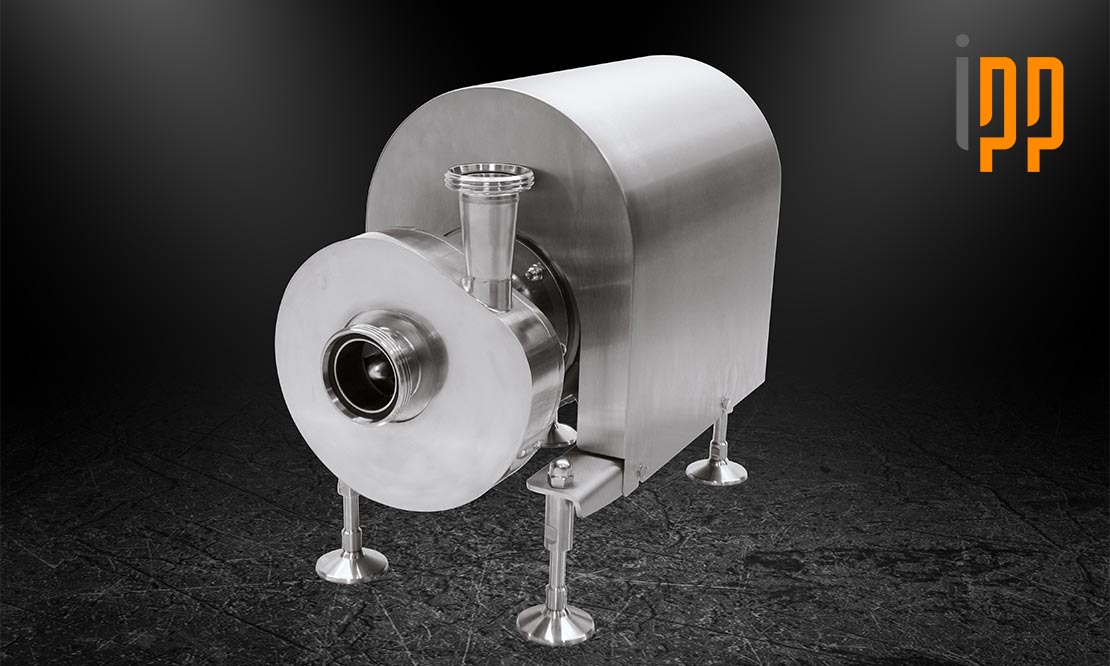

The Aqueous centrifugal pump is characterized by its hygienic design, a flow rate of up to 300 m³/h (1230 gpm) and delivery heads of up to 120 m (393 ft). With its unrestricted CIP and SIP capability, ATEX certification and suitability for high system pressures, it sets new standards in terms of robustness, flexibility and quality.

The components of the Aqueous centrifugal pump are machined from rolled material. This has decisive advantages over conventional pump systems. The standard surface quality of Ra ≈ 0.8 µm ensures easy cleaning and therefore reliable processes. This surface quality has a positive influence on efficiency. The dimensional accuracy ensures consistent quality in terms of the reproducibility of the hydraulic operating points and in relation to the rotational dynamics. Imbalances are minimised by design.

At the same time, there are no dependencies with regard to cast or sheet metal semi-finished products, which results in maximum flexibility in terms of material selection and geometric requirements in order to meet the needs in the field.

In the system, the hygienic centrifugal pump has a minimal footprint as a short block pump. For easy maintenance, the housing can remain connected to the pipework so that only the back pull-out unit (BPU) is retracted. All relevant parts are then accessible from the front.

Thanks to its modular design and high-quality materials, such as stainless steel 1.4404, the Aqueous centrifugal pump meets the highest hygiene standards and offers a wide range of equipment options for individual customer solutions. Ideal for applications in the beverage, food and pharmaceutical industries, it ensures reliable and long-lasting operation.