In a production process not yet recognized of any potential for plastic pumps operators turn out to be very grateful when MUNSCH pumps successfully substitute a none-clogging wastewater pump from cast iron and reduce the cost of pump repair significantly. The Munsch pump from Polyethylene not only turns out to be inert against the acidic water but also more abrasion resistant while handling fairly large amounts of glass fiber, limestone and other contaminations – without showing any sign of wear. It all started with a curious Munsch engineer having a pump chat …

Because at MUNSCH they are all curious people, one day one of them stumbled into a factory producing kilometers of mineral wool mat from glass fibers every day. In a general discussion about pumps, it turned out to be a production line with not many chemicals involved and no obvious need for corrosion resistant plastic pumps. Just water and fibers.

Fig. 1 – Large contents of glass fiber and

particles work heavily on all equipment involved.

Task

A major manufacturer for the insulation material is struggling with streams of glass fiber slurries that frequently ruin metallic heavy-duty wastewater pumps. A simple solution with Munsch plastic pumps appears futile at the beginning but surprisingly turns out as a real cost saver.

When the plant operators mention serious wear problems with heavy-duty wastewater pumps from cast iron however, the Munsch engineer starts digging and reveals that it is not only the massive amount of glass fiber and particles damaging those pumps but also its combination with corrosion induced by the slightly acidic process water. This lead to a form of corrosion also known as erosion corrosion. The combined attack of corrosion and abrasion results frequently in a total loss or extensive repair work within less than three months for many of the numerous pumps throughout the plant.

Repair and replacement cost for the large non-clogging pumps and considerable amounts of caustic soda for partial neutralization of water were unreasonably high at that time.

The operators agree without hesitation when MUNSCH offers a test pump from wear resistant Polyethylene even though they have some doubts if the plastic could handle the huge amounts of fibers and particles.

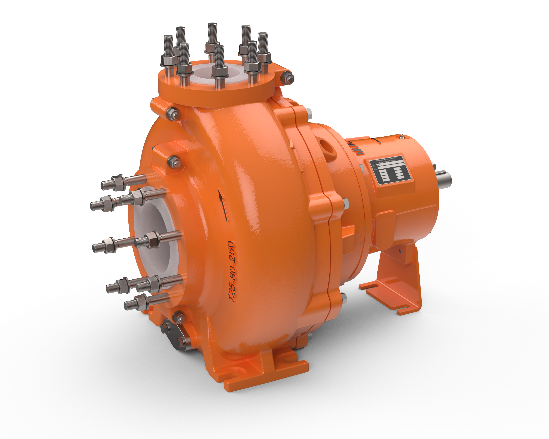

Fig. 2 – MUNSCH Heavy Duty Plastic Centrifugal Pump – Series NCP

Solution

MUNSCH decided to offer a specialized centrifugal pump hydraulic with a rugged single mechanical seal. The pump is installed shortly after and – much to the operator’s surprise – the plastic pump accomplishes its task instantly without any struggles.

It was agreed to open the pump for inspection after six month of continuous operation and, in fact, it showed hardly any wear on any of the wetted parts. Even the mechanical seal area was nice and clean. Within two years, the customer has replaced eleven large non-clogging pumps from cast iron and stainless steel and plans further substitutes throughout the plant.

MUNSCH designs and produces efficient centrifugal plastic pumps – not just for acids and toxic chemicals. Sometimes these pumps are just a big help in process water being at ease with amounts of chlorides, fluorides or solids. These pumps are industrial grade from small to XXL, meaning 2-3000 m3/h.

Fig. 3 – MUNSCH NP 200-150-250 made of polyethylene (UHMW-PE)

without wear after 6 months