Exploring Vacuum Pump Innovations at the 138th Canton Fair 2025: Trends and Data Insights

The 138th Canton Fair in 2025 presents a remarkable opportunity to delve into the latest trends and innovations in the vacuum pump industry. As a pivotal platform for global trade, this biennial event will showcase cutting-edge technologies and solutions that are shaping the future of vacuum systems. With industries increasingly relying on vacuum pumps for a variety of applications, including manufacturing, healthcare, and environmental management, the Fair is set to highlight the significant advancements that are improving efficiency and sustainability.

Attendees can expect to gain valuable data insights and engage with industry leaders who are pioneering developments in vacuum pump technology. This introduction will explore the prevailing innovations and set the stage for a comprehensive understanding of how these advancements are influencing market dynamics and driving growth in the vacuum pump sector.

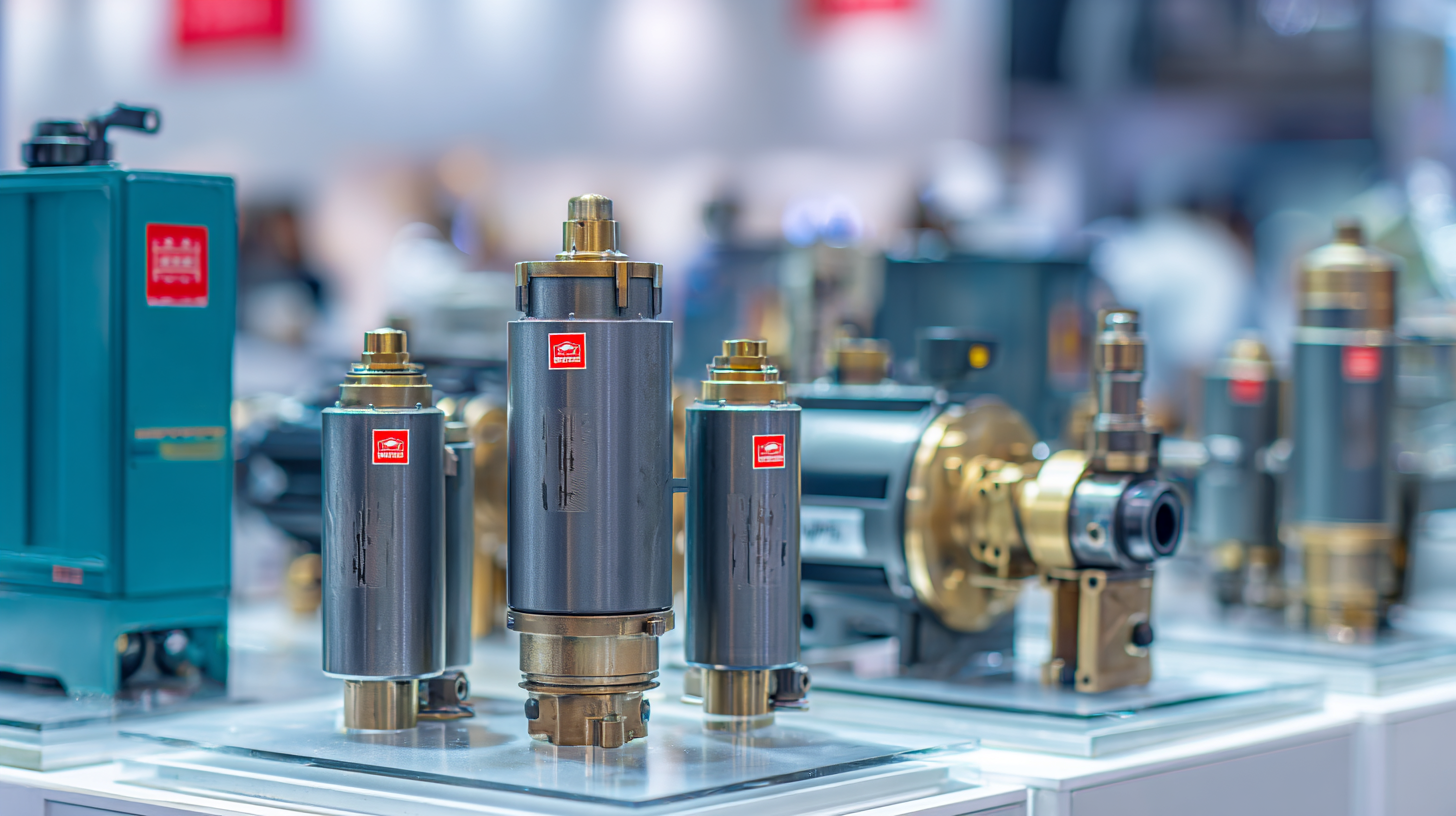

Innovative Vacuum Pump Technologies Showcased at the 138th Canton Fair 2025

At the 138th Canton Fair 2025, the spotlight was cast on innovative vacuum pump technologies that are reshaping industrial applications and enhancing efficiency. Key exhibitors unveiled advancements in high-performance pumps that utilize cutting-edge materials and designs to improve energy efficiency. According to a recent industry report by Market Research Future, the global vacuum pump market is projected to reach $5.8 billion by 2027, growing at a CAGR of 6.1%. This growth underscores the increasing demand for advanced vacuum solutions in various sectors, including pharmaceuticals, food processing, and semiconductor manufacturing.

Notably, manufacturers showcased smart vacuum pumps equipped with IoT capabilities, enabling real-time monitoring and predictive maintenance. This shift towards intelligent systems reflects a broader trend highlighted in a survey by the International Society for Automation, which found that over 70% of industries are integrating smart technologies to enhance operational efficiency. These innovations presented at the Canton Fair promise to not only reduce operational costs but also minimize environmental impact, aligning with the global push for sustainable practices in manufacturing.

Market Growth Projections for Vacuum Pump Industry: A Deep Dive into 2025 Trends

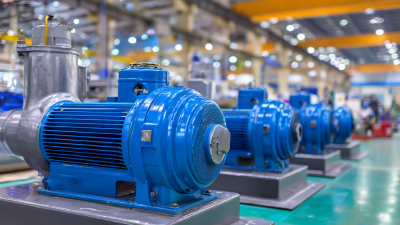

The vacuum pump industry is poised for significant growth, with projections indicating robust market expansion through 2025. As pharmaceutical manufacturing continues to evolve, the demand for specialized equipment, including vacuum pumps, is expected to rise. This trend is closely tied to advancements in production technologies and increasing regulatory standards, which drive manufacturers to integrate efficient and reliable systems into their operations. The market's growth is underscored by the increasing need for automation and precision in drug manufacturing processes.

In addition to the vacuum pump market, related sectors such as air compressor and vacuum cooling equipment are also experiencing upward trends. The global air compressor market is projected to grow from $18.96 billion in 2025 to $29.31 billion by 2032, reflecting a compound annual growth rate (CAGR) of 6.4%. Similarly, the vacuum cooling equipment market is forecasted to increase, reaching approximately $115.8 million by 2032. These trends highlight a broader movement towards innovation and efficiency in industrial applications, particularly within the pharmaceutical sector, where the integration of such equipment is critical for enhancing productivity and quality control.

Vacuum Pump Market Growth Projections (2023-2025)

The global vacuum pump market is projected to grow steadily from 2023 to 2025, reaching $5.8 billion by 2025. This growth is driven by increasing industrial applications, technological advancements, and expanding end-use sectors.

Sustainability in Vacuum Pump Design: Eco-Friendly Solutions at the Canton Fair

The 138th Canton Fair in 2025 is set to showcase groundbreaking innovations in vacuum pump technology, with a significant focus on sustainability. Eco-friendly design is becoming increasingly essential, as manufacturers aim to minimize their environmental impact. Modern vacuum pumps are now integrating sustainable materials and energy-efficient components, aligning with global trends toward greener practices. Exhibitors at the fair will highlight advancements that not only enhance performance but also reduce carbon footprints.

**Tips:** When exploring eco-friendly vacuum pump options, look for models made from recyclable materials and those that employ energy-efficient operation modes. Additionally, consider the manufacturer's commitment to sustainable practices in their production processes.

As we delve deeper into the eco-friendly solutions presented at the fair, it’s important to note that innovation in this area enables businesses to operate more responsibly. From utilizing solar power to developing biodegradable parts, the industry is shifting toward sustainable solutions that cater to the burgeoning demand for environmentally conscious products. Attendees can expect to see a variety of designs that prioritize both functionality and eco-sensitivity, providing a glimpse into the future of vacuum pump technology.

**Tips:** Investigate companies that offer transparent sustainability reports and certifications for their products to ensure you are making an environmentally friendly choice.

Exploring Vacuum Pump Innovations at the 138th Canton Fair 2025

| Vacuum Pump Type | Energy Efficiency (%) | Noise Level (dB) | Weight (kg) | Sustainability Rating |

|---|---|---|---|---|

| Single Stage Rotary Vane | 85 | 60 | 20 | A |

| Dual Stage Scroll Pump | 90 | 55 | 15 | A+ |

| Oil-Free Diaphragm Pump | 80 | 50 | 12 | A++ |

| Liquid Ring Vacuum Pump | 75 | 70 | 25 | B |

Data-Driven Insights: Analyzing Consumer Preferences for Vacuum Pumps in 2025

At the 138th Canton Fair 2025, the spotlight on vacuum pump innovations offers a unique opportunity to analyze consumer preferences driven by significant data insights. Throughout the event, trends indicate a growing demand for energy-efficient models that not only minimize operational costs but also enhance overall performance. Consumers increasingly prioritize sustainability and are gravitating toward vacuum pumps that incorporate eco-friendly technologies, reflecting a broader shift towards green practices in industrial applications.

Moreover, data analytics reveal that users are interested in advanced features such as IoT connectivity and remote monitoring capabilities. These technological advancements allow for more efficient maintenance and operation, appealing to a demographic that values not only functionality but also ease of use. The integration of smart technology in vacuum pumps resonates particularly well with the younger, tech-savvy consumers who prioritize innovation and adaptability in industrial equipment. This evolving landscape underscores the importance of understanding consumer preferences in shaping the future of vacuum pump manufacturing and marketing strategies.

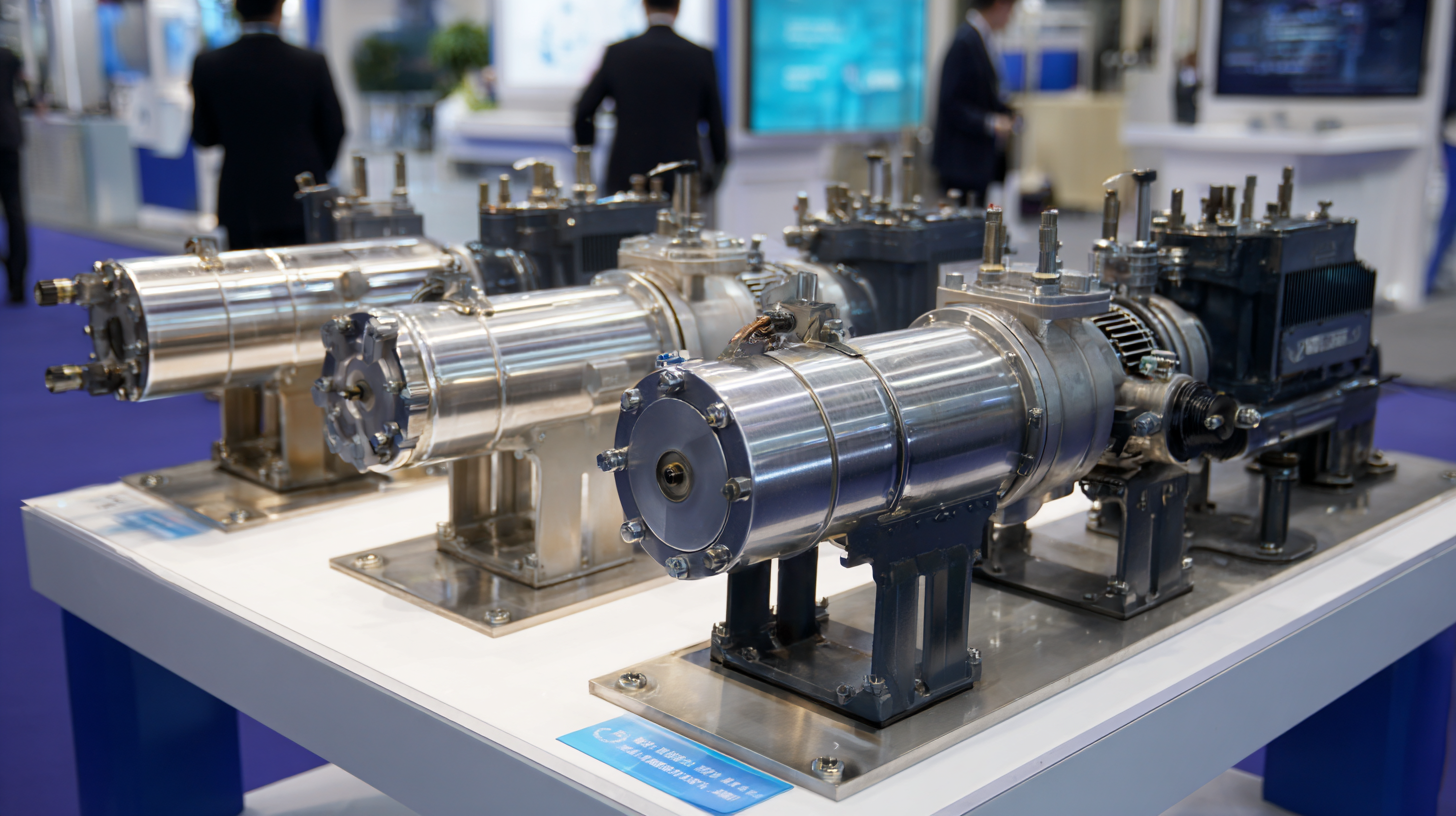

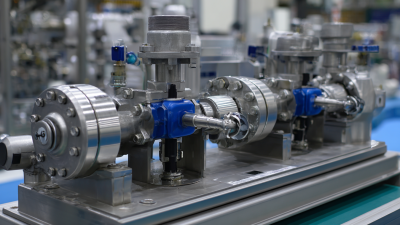

The Role of Automation in Vacuum Pump Innovations: Enhancing Efficiency and Performance

The 138th Canton Fair 2025 highlighted the transformative role of automation in vacuum pump innovations, marking a pivotal shift in efficiency and performance metrics within the industry. According to a recent report by MarketsandMarkets, the global vacuum pump market is projected to reach $4.6 billion by 2026, growing at a CAGR of 4.1%.

This growth is largely attributed to the integration of advanced automation technologies that streamline operations, reduce downtime, and enhance product reliability.

Automation in vacuum pump systems not only optimizes operational efficiency but also minimizes energy consumption. Data from the International Energy Agency shows that automated systems can lead to energy savings of up to 30% compared to traditional methods. In sectors like pharmaceuticals and semiconductor manufacturing, where precision and reliability are paramount, these innovations have become indispensable.

The use of IoT-enabled sensors and real-time monitoring ensures that any anomalies are detected swiftly, allowing for predictive maintenance and significantly reducing the risk of unexpected failures. As the industry continues to evolve, the intersection of automation and vacuum technology is set to play a crucial role in driving performance advancements.

Related Posts

-

How to Select the Right Chemical Pump for Your Industrial Needs

-

How to Choose the Right Gas Transfer Pump for Your Industrial Needs

-

How to Select the Right Diaphragm Pump for Your Industrial Needs

-

How to Choose the Right Suction Pump for Your Industrial Needs

-

Mastering Dosing Pumps: A Step-by-Step Guide to Optimal Use and Maintenance

-

How to Choose the Right Centrifugal Pump for Your Industrial Needs