Everything You Need to Know About Transfer Tank Pumps: Your Ultimate Guide to Safe Fuel Handling

When it comes to safely handling and transferring fuel, understanding the mechanics and best practices of a transfer tank pump is essential. This ultimate guide is designed to equip you with everything you need to know about these vital tools. From the types of transfer tank pumps available on the market to their specific uses and safety measures, we will cover all aspects that ensure efficient fuel management while preventing spills and accidents. Whether you are a contractor, fleet manager, or a DIY enthusiast, knowing how to properly select, operate, and maintain your transfer tank pump will not only enhance your workflow but also contribute to a safer environment. Dive into this comprehensive resource to unlock the potential of your fuel transfer operations and safeguard your assets.

Understanding Transfer Tank Pumps and Their Importance

Transfer tank pumps play a crucial role in the safe handling of fuel, ensuring that the transfer process is both efficient and compliant with safety regulations. These pumps allow users to manage fuel transferring from one tank to another without the risk of spills or leaks, thus minimizing environmental impact. Understanding the functionality and importance of transfer tank pumps can enhance safety measures in various industries, particularly in terms of preventing hazardous situations.

When setting up a fuel transfer system, it is fundamental to consider a few tips: First, ensure the pump you're choosing is compatible with the type of fuel you plan to transfer, as different fuels require different pump insights. Second, regularly check all fittings and hoses to confirm they are secure and free of leaks, as even minor issues can lead to significant problems. Lastly, always monitor the fuel quantity and maintain proper documentation to create a transparent operation that secures trust among users and regulations alike.

Key Features to Look for in Transfer Tank Pumps

When selecting transfer tank pumps, it's crucial to focus on key features that ensure both safety and efficiency in fuel handling. Firstly, consider the pump's flow rate, usually measured in gallons per minute (GPM). According to a recent report by the Petroleum Equipment Institute, pumps with a flow rate of 15-20 GPM are optimal for most applications, providing a balance between speed and control. Additionally, pumps equipped with automatic shut-off systems can significantly reduce the risk of spills, a critical factor given that the Fuels Institute reported that over 5,000 fuel spills occur annually, leading to environmental hazards and costly fines.

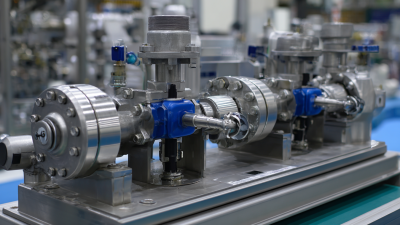

Another essential feature is the construction material of the pump. Opting for high-quality, corrosion-resistant materials—such as aluminum or stainless steel—can enhance the longevity and durability of the pump. Furthermore, look for pumps that have undergone rigorous testing and certification, like those approved by Underwriters Laboratories (UL). These certifications ensure that the pumps meet essential safety standards, reducing the risk of hazardous incidents. As the market for transfer tanks continues to grow, with projections showing a rise to $3.5 billion by 2025, prioritizing these features will be vital for operators looking to protect both their assets and the environment.

Best Practices for Safe Fuel Handling and Transfer

When managing fuel transfers, adhering to best practices is essential for ensuring safety and compliance. According to the National Fire Protection Association (NFPA), improper fueling practices lead to over 3,000 incidents annually, highlighting the importance of proper procedures. To mitigate risks, users should always work within a well-ventilated area away from ignition sources, as vapors can easily ignite in confined spaces.

Tips: Always wear appropriate personal protective equipment (PPE) like gloves and goggles when handling fuel. Regularly inspect transfer tank pumps for leaks and ensure they are mechanically sound to prevent spills.

Tips: Always wear appropriate personal protective equipment (PPE) like gloves and goggles when handling fuel. Regularly inspect transfer tank pumps for leaks and ensure they are mechanically sound to prevent spills.

Additionally, familiarize yourself with local regulations regarding fuel handling. Industry reports indicate that compliance with these regulations not only minimizes risks but can also enhance operational efficiency. Keeping a spill kit on hand is also vital in case of accidents, ensuring a prompt response to fuel spills to minimize environmental impact and adhere to legal obligations.

Tips: Document your fuel transfer procedures and conduct regular training sessions for employees to reinforce safe handling techniques. Engaging staff in safety checks can create a culture of safety and accountability.

Common Mistakes to Avoid When Using Transfer Tank Pumps

When using transfer tank pumps for fuel handling, it's crucial to avoid common mistakes that can lead to safety hazards or equipment failure. One frequent error is overfilling the tank. Operators often underestimate the amount of fuel being transferred, risking spills that can cause environmental damage and violate regulations. To prevent this, it's important to monitor the flow closely and set up an automatic shut-off system if possible.

Another common mistake is neglecting proper maintenance of the pump and associated equipment. Many users overlook regular inspections and repairs, which can lead to decreased efficiency and malfunction during critical operations. It's vital to follow a maintenance schedule that includes checking for leaks, ensuring filter cleanliness, and testing emergency shut-off features. By taking these precautions, users can significantly enhance safety and efficiency in their fuel transfer processes.

Regular Maintenance Tips for Long-Lasting Performance of Transfer Tank Pumps

Regular maintenance of transfer tank pumps is essential for ensuring their longevity and optimal performance. One crucial aspect of this maintenance involves regularly cleaning the fuel tank. Contaminants can accumulate over time, leading to clogs and reduced efficiency. A clean tank not only extends the life of the fuel pump but also helps prevent potential issues caused by ethanol-blended fuels, such as E10, which can cause damage to fuel systems if not properly managed.

Additionally, checking the pump's seals and hoses for any signs of wear or leaks can prevent costly repairs and enhance safety during fuel transfer. Given the increasing use of biofuels and their effects on fuel systems, it’s vital to adapt maintenance strategies accordingly. By adhering to proper upkeep practices, users can mitigate the risks associated with 'dreaded villains' like ethanol-blended petrol and ensure their transfer tank pumps operate smoothly and effectively.

Fuel Transfer Tank Pump Maintenance: Performance Over Time

This bar chart illustrates the correlation between regular maintenance frequency and the performance longevity of transfer tank pumps. As maintenance frequency increases, the average lifespan of the pumps also improves significantly.

Related Posts

-

7 Reasons to Choose a Diesel Transfer Tank with Pump for Your Business

-

How to Choose the Right Fuel Transfer Tank with Pump for Your Needs

-

How to Select the Right Chemical Pump for Your Industrial Needs

-

How to Choose the Right Chemical Pump for Your Industry Needs

-

How to Choose the Right Gas Transfer Pump for Your Industrial Needs

-

Exploring the Benefits of Air Operated Diaphragm Pumps: A Comprehensive Guide for Industrial Applications