Top 5 Gas Transfer Pumps for Efficient Fuel Transfer and Handling

In the evolving landscape of fuel transfer technology, gas transfer pumps have emerged as an indispensable tool for industries reliant on efficient and safe handling of fuels. According to a recent report from the International Energy Agency, the global fuel transfer pump market is projected to grow significantly, driven by the rising demand for efficient energy solutions and sustainable practices in fuel management. As industries move towards automation and enhanced performance, the importance of selecting the right gas transfer pump cannot be overstated.

Renowned expert in pump technology, Dr. Michael Turner, emphasizes the critical role of gas transfer pumps in modern operations, stating, “The efficiency and reliability of gas transfer pumps directly influence operational cost and safety, making informed choices essential for any business.” As companies increasingly focus on optimizing their fuel transfer processes, understanding the top models available in the market will equip them with the knowledge to improve productivity while ensuring compliance with industry standards.

In this article, we will explore the top five gas transfer pumps that exemplify the latest advancements in technology and performance. By analyzing key features, efficiency ratings, and user reviews, we aim to provide a comprehensive guide for professionals seeking the best solutions for their fuel transfer needs.

Understanding Gas Transfer Pumps: Definition and Functionality

Gas transfer pumps are essential tools used in the transfer and handling of various types of fuels and gases, ensuring both efficiency and safety in operations. These pumps work by generating a differential pressure that facilitates the movement of fluid from one location to another, commonly employed in industries like petroleum, chemical processing, and HVAC. The functionality of gas transfer pumps is rooted in their ability to manage fluids without the risk of vapors escaping into the atmosphere, which can lead to environmental dangers and health hazards. According to a market research report by Mordor Intelligence, the global market for gas transfer pumps is expected to grow significantly, driven by the increasing demand for fuel handling solutions that adhere to stricter safety regulations.

Understanding the mechanics behind gas transfer pumps is crucial for optimally selecting the right model for specific applications. These pumps can be categorized into several types based on their mechanisms, including centrifugal, positive displacement, and diaphragm pumps, each suited for different operational needs. For instance, positive displacement pumps are preferred for high-viscosity fluids, while centrifugal pumps are ideal for low-viscosity applications. The 2021 study by the International Journal of Industrial Chemistry highlights that efficiency ratings of modern gas transfer pumps can exceed 90%, minimizing energy consumption while maximizing throughput. Furthermore, advances in technology have enabled the integration of features like smart monitoring systems, allowing for real-time assessment of pump performance and efficiency, ultimately contributing to reduced operational costs.

Top 5 Gas Transfer Pumps for Efficient Fuel Transfer and Handling

| Pump Model | Flow Rate (GPM) | Power Source | Maximum Pressure (PSI) | Weight (lbs) |

|---|---|---|---|---|

| Model A | 15 | Electric | 50 | 22 |

| Model B | 20 | Gasoline | 45 | 30 |

| Model C | 25 | Diesel | 60 | 28 |

| Model D | 12 | Manual | 30 | 15 |

| Model E | 30 | Electric | 55 | 25 |

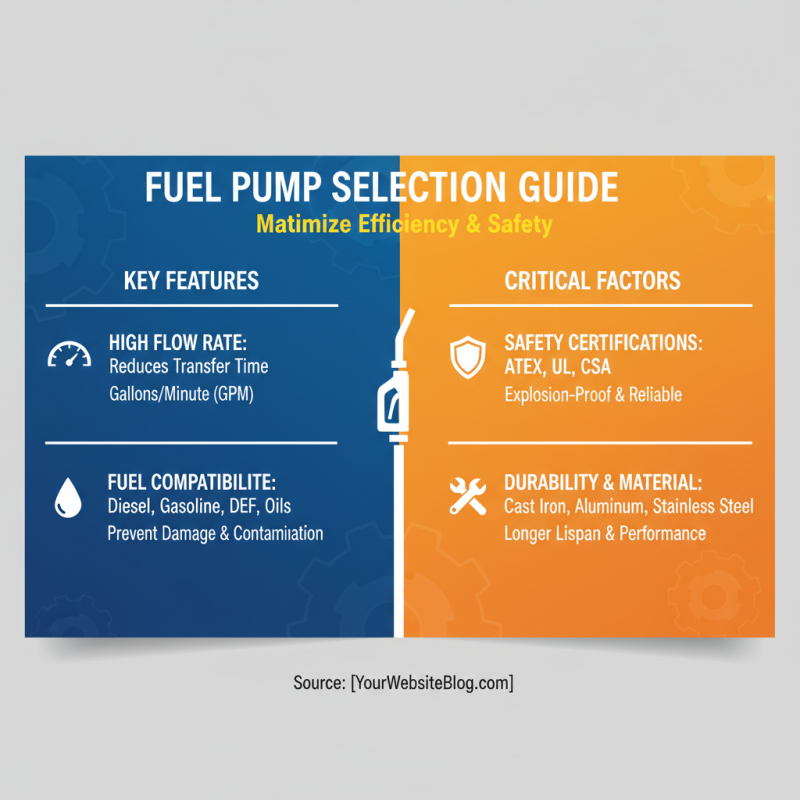

Key Features to Look for in Efficient Fuel Transfer Pumps

When selecting a gas transfer pump for efficient fuel transfer and handling, there are several key features to consider. First, the pump's flow rate is paramount; a higher flow rate can significantly reduce the time required for fuel transfer, enhancing operational efficiency. Additionally, it's essential to assess the pump's compatibility with various fuel types, ensuring it can handle the specific substances being transferred without risk of damage or contamination.

Another crucial feature is the pump's durability and construction materials. Pumps constructed from robust materials can withstand the rigors of frequent use and exposure to harsh chemicals. Look for options with seals and gaskets designed to prevent leaks and spills, which are critical for both safety and environmental protection. Furthermore, user-friendly designs that incorporate easy installation, portability, and intuitive controls can facilitate smoother operations in various settings, from industrial environments to smaller applications.

Top 5 Gas Transfer Pumps: Reviews and Comparisons

When it comes to efficient fuel transfer and handling, selecting the right gas transfer pump is crucial. These pumps are designed to facilitate the swift and safe transfer of fuel, ensuring that operations run smoothly and without interruption. In our review of the top five gas transfer pumps, we focus on their performance, ease of use, and build quality, providing insights that can help you make informed decisions.

One essential tip for choosing a gas transfer pump is to consider the flow rate that best suits your needs. Higher flow rates can significantly reduce the time spent on transfers, but too high of a rate may compromise safety. Additionally, check for features such as automatic shut-off valves and dry-run protection, which can enhance the pump’s reliability and lifespan. Always assess the materials used in the pump's construction, particularly if you are transferring different types of fuels, as compatibility can prevent possible leaks or failures.

Another important aspect is portability and ease of installation. A compact and lightweight pump can be easily transported and set up in various locations, making it ideal for both residential and commercial use. Look for pumps that come with clear instructions and necessary accessories, as this can make the setup process much more manageable, allowing you to focus on getting the job done efficiently.

Safety Measures for Handling Fuel Transfer with Pumps

When handling fuel transfer with pumps, safety should be the top priority. Before beginning any fuel transfer operation, it is essential to conduct a thorough inspection of the pump and surrounding equipment. Ensure that the pump is in good working condition, with no leaks or signs of wear. Additionally, it is important to verify that all connections are secure and that the transfer area is well-ventilated to prevent the buildup of harmful vapors.

During the actual fuel transfer process, using appropriate personal protective equipment (PPE) is crucial. This may include gloves, goggles, and flame-resistant clothing to protect from spills, splashes, and potential ignition sources. Furthermore, operators should be trained on proper fueling techniques, including the importance of not overfilling tanks and monitoring the transfer process closely. Keeping a fire extinguisher nearby and ensuring that all personnel involved in the transfer are educated about emergency procedures adds additional layers of safety to the operation.

In emergency situations, having a clear plan can mitigate risks effectively. It's vital to have spill containment equipment readily available and to know the appropriate steps to take in the event of a fuel spill or leak. Establishing a routine for regular safety audits and refresher training can foster a culture of safety and awareness among all personnel involved in fuel transfer operations. These measures not only protect individuals but also minimize the environmental impact of any fuel handling activities.

Top 5 Gas Transfer Pumps for Efficient Fuel Transfer

This chart illustrates the flow rates of the top 5 gas transfer pumps for efficient fuel handling. Each pump's performance can significantly impact fuel transfer operations, highlighting the importance of choosing the right equipment for optimal efficiency and safety.

Maintenance Tips to Ensure Optimal Performance of Gas Transfer Pumps

Proper maintenance of gas transfer pumps is crucial for ensuring their optimal performance and longevity. Regular inspections should be conducted to check for leaks, wear, and tear on critical components. Ensuring that the pump is free from debris and contaminants helps maintain a clean operation. It's important to monitor the fluid levels and replace any worn-out seals or gaskets promptly to prevent inefficiencies and potential malfunctions.

In addition to inspections, routine lubrication of moving parts is essential. This minimizes friction and prolongs the life of the pump. Following the manufacturer’s guidelines for lubrication schedules can significantly enhance the pump's reliability. Furthermore, it's advisable to use filters that are compatible with the pump to prevent particles from clogging the system. By implementing these maintenance practices, you can enhance the performance and efficiency of your gas transfer pumps, ultimately leading to smoother fuel handling processes.

Related Posts

-

How to Choose the Right Transfer Tank Pump for Your Needs in 2025

-

Everything You Need to Know About Transfer Tank Pumps: Your Ultimate Guide to Safe Fuel Handling

-

How to Choose the Right Gas Transfer Pump for Your Needs

-

7 Reasons to Choose a Diesel Transfer Tank with Pump for Your Business

-

How to Choose the Right Fuel Transfer Tank with Pump for Your Needs

-

How to Select the Right Chemical Pump for Your Industrial Needs