2026 Top Dosing Pump Innovations for Various Industries?

In recent years, the dosing pump industry has experienced remarkable innovations. Experts, like John Smith, a leading figure in fluid dynamics, emphasize the significance of these advancements. He states, "Dosing pumps are revolutionizing how we manage chemical processes."

Innovation is crucial across various industries. From water treatment to pharmaceuticals, dosing pumps play a vital role. They ensure precise chemical distribution, enhancing efficiency and safety. The introduction of smart technology has taken these pumps to a new level. Automated systems now track usage in real-time, allowing for better adjustments and waste reduction.

However, not every new technology has been flawless. Some innovations have led to unexpected challenges. Companies must adapt to these changes, ensuring their workers are trained adequately. The dosing pump market continues to evolve, offering both opportunities and hurdles. This dynamic landscape invites industry leaders to rethink their strategies as they embrace the future.

Latest Advances in Dosing Pump Technology for 2026 Across Major Industries

The dosing pump industry is witnessing remarkable advancements in 2026. New technologies are emerging to enhance efficiency and precision. These innovations cater to various sectors, such as pharmaceuticals, food and beverage, and chemical processing.

New dosing mechanisms are being developed for accurate flow rates. Digital controls are improving user interfaces. This allows operators to adjust settings quickly. However, not all innovations achieve the expected performance. Some users report inconsistencies. Reliability remains a significant concern as the industry evolves.

Moreover, the integration of IoT technology is transforming operations. Real-time data monitoring helps predict maintenance needs. It reduces downtime but can be complex to implement. Training is necessary for staff to adapt to these changes. As the market expands, the need for robust solutions continues to grow.

Key Innovations in Chemical Processing Dosing Pumps: A 2026 Overview

Chemical processing industries are witnessing remarkable innovations in dosing pump technologies for 2026. One key advancement is the introduction of smart dosing pumps. These devices utilize IoT technologies for real-time monitoring. Operators can adjust settings remotely, improving efficiency. Additionally, these pumps can provide alerts for maintenance, thus minimizing downtime. However, reliance on technology raises concerns about cybersecurity.

Another noteworthy trend is the development of more efficient pump designs. Improved materials and engineering techniques enhance durability. This reduces the need for frequent replacements and lower operational costs. Yet, some companies may overlook the importance of proper training in using these new systems. Misuse can lead to accidents or inefficiencies.

Moreover, sustainable practices are shaping the industry. Pumps that minimize waste and energy use are becoming standard. This shift often requires a cultural change within organizations, which can be challenging. Some employees may resist new methods or feel overwhelmed by the transition. It’s crucial to address these challenges to maximize the potential of innovations in dosing pumps.

2026 Top Dosing Pump Innovations Overview

| Innovation | Industry Application | Key Features | Expected Impact |

|---|---|---|---|

| Smart Pump Monitoring | Chemical Processing | Real-time data analytics, remote monitoring | Reduction in downtime, improved efficiency |

| Eco-Friendly Materials | Water Treatment | Sustainable construction, recyclable components | Lower environmental impact, cost savings |

| Variable Speed Control | Pharmaceuticals | Precise flow rate adjustments, energy efficiency | Increased accuracy, reduced energy costs |

| Modular Pump Design | Food Processing | Customizable setups, easy maintenance | Flexibility in production, lower maintenance time |

| AI-Driven Optimization | Oil & Gas | Predictive analytics, fault detection | Enhanced safety, improved production rates |

2026 Trends in Dosing Pump Efficiency: Energy Savings and Performance Metrics

As industries evolve, dosing pump technology aims to enhance efficiency. Energy savings become crucial. Companies look for ways to minimize waste. Modern pumps offer precise flow rates. This precision reduces overuse of resources. However, some systems require regular maintenance, which can offset savings.

In 2026, performance metrics will focus on energy consumption. Users will need to analyze data more frequently. Software tools will help track efficiency over time. This insight reveals patterns that may need adjustments. Yet, not all equipment delivers expected results. Some users may overlook key factors in optimization.

Integration of smart technology will shape future trends. Automation will streamline processes, but it demands precise programming. Not all operators will adapt quickly. Continuous training is essential to harness these innovations effectively. The road ahead is filled with potential, yet challenges remain.

Impact of Smart Technology and IoT on Dosing Pump Applications in 2026

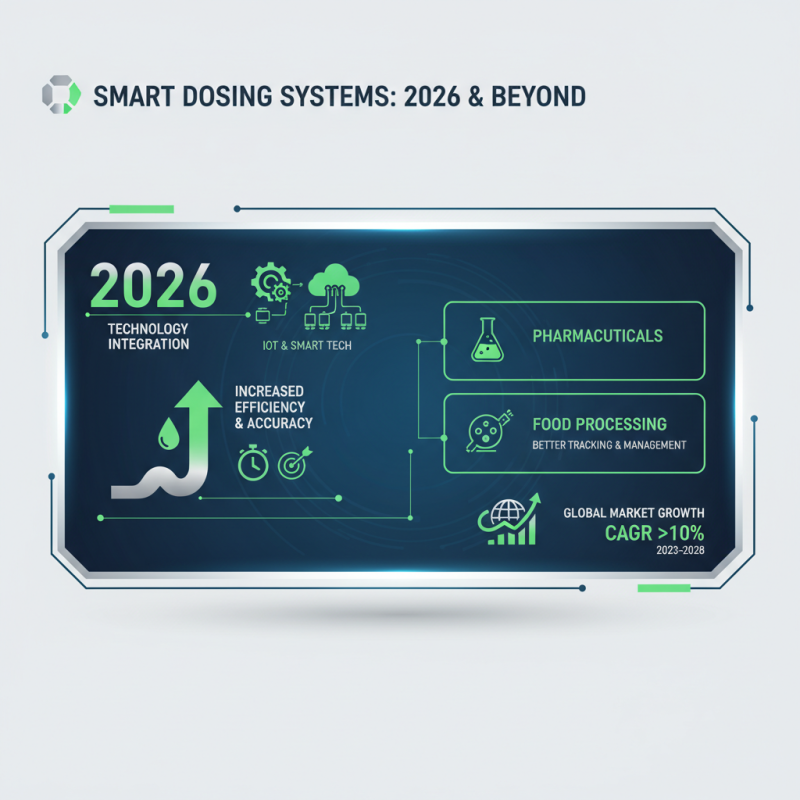

In 2026, the integration of smart technology and IoT in dosing pumps will lead to significant advancements. These innovations promise increased efficiency and accuracy in fluid dispensing across various industries. Industries like pharmaceuticals and food processing can expect better tracking and management of their dosing systems. The global market for smart dosing systems is projected to grow substantially, with an expected CAGR of over 10% from 2023 to 2028.

Dosing pumps equipped with IoT features will enable real-time monitoring. This capability ensures that any deviations in fluid measurements are immediately detected. For instance, predictive maintenance alerts can prevent downtimes, optimizing operational costs. A recent industry report highlights that companies utilizing smart dosing technology could reduce fluid waste by 20%. This efficiency leads to both cost savings and environmental benefits.

Tip: Regularly assess the performance of dosing pumps in your operations. Monitoring real-time data helps in identifying inefficiencies early.

Moreover, challenges still exist with smart dosing technology. Integration with existing systems may require significant investment. Many companies face hurdles in training staff to handle advanced features. Overcoming these challenges is crucial for maximizing benefits. Continuous adaptation and learning will be vital as the industry evolves.

Tip: Invest in staff training to fully utilize new technologies. Engaged employees can better implement and maintain smart dosing solutions.

Comparative Analysis of Dosing Pump Solutions for Food and Beverage Industries

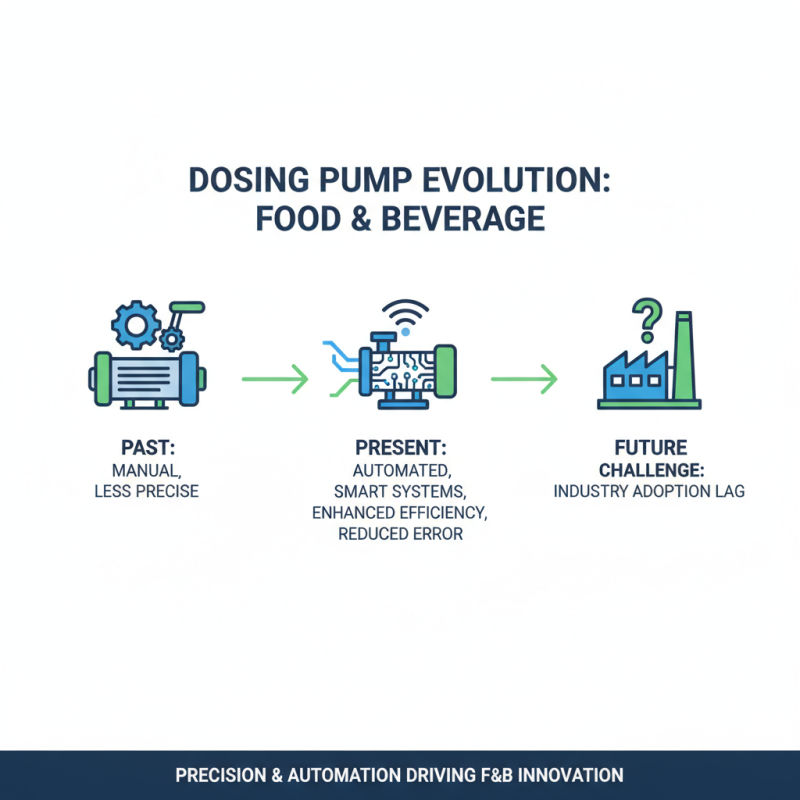

In recent years, dosing pumps have evolved significantly in the food and beverage industry. These innovations enhance precision and efficiency. The drive for automation is strong. Many solutions now integrate with smart systems. This reduces human error. However, some industries still lag behind in adopting these technologies.

One key innovation is the use of sanitary materials. These materials prevent cross-contamination, ensuring product safety. Many pumps now feature easy-clean designs. This is crucial for maintaining hygiene. The ability to quickly disassemble pumps can save valuable time. Nonetheless, not every facility has adopted these practices. Some companies hesitate to invest in upgrades.

**Tips:** Regular maintenance is essential. Check for wear and tear on seals. An overlooked small issue can lead to bigger problems. Also, training staff on proper use is vital. Misuse can compromise the entire system. Different types of dosing pumps serve various needs. Choose the right one for your application.

Related Posts

-

Top 5 Dosing Pumps for 2023 Boost Efficiency and Precision in Fluid Management

-

Top 10 Chemical Dosing Pump Questions Answered

-

Mastering Dosing Pumps: A Step-by-Step Guide to Optimal Use and Maintenance

-

How to Choose the Right Chemical Dosing Pump for Your Industrial Needs

-

Top Strategies for Enhancing Efficiency with Metering Pumps

-

How to Select the Right Chemical Pump for Your Industrial Needs