Top 5 Tips for Choosing an Industrial Vacuum Pump?

When selecting an industrial vacuum pump, it's crucial to understand your specific needs. Dr. Emily Smith, an expert in industrial vacuum technology, emphasizes, "Choosing the right pump can greatly impact efficiency and safety." This statement resonates deeply in a world where effective vacuum solutions are essential for various industries.

Considerations like pump size, application type, and maintenance are key. An industrial vacuum pump needs to fit your operational requirements. Additionally, understanding the type of materials you will handle is vital. This process exposes many potential pitfalls, like oversizing a pump or neglecting serviceability. Such mistakes could lead to reduced efficiency or increased costs.

Navigating through the options available can feel overwhelming. Each pump has its unique specifications, which can create confusion. Take the time to assess your environment and specific operational demands. The right industrial vacuum pump should not only perform well but also integrate seamlessly into your workflow. Aim for a choice that enhances productivity while minimizing unexpected downtime.

Understanding the Different Types of Industrial Vacuum Pumps

When selecting an industrial vacuum pump, understanding the various types is essential. There are positive displacement pumps, which are known for their efficiency in handling large volumes of air and gases. These pumps are great for heavy-duty applications. On the other hand, momentum transfer pumps, like rotary vane pumps, are commonly used in smaller areas where precision is needed. They provide a cleaner and quieter operation.

Consider the application carefully. Assess if you need a pump for continuous operation or intermittent use. Vacuum levels also matter. Some processes might require a rough vacuum, while others demand high vacuum levels. Devices like oil-sealed pumps can deliver better performance but may require more maintenance.

When making your choice, remember to evaluate the maintenance and operational costs. Less maintenance could save time, but might come with a higher initial cost. Reflect on how often you will use the pump. More frequent use demands better quality. Test different options. Not every model will work for your needs, and sometimes, trial and error is necessary to find the right fit. Choose wisely, as the right pump can enhance your operational efficiency significantly.

Evaluating Performance Specifications for Your Application Needs

Choosing the right industrial vacuum pump is crucial for efficiency and cost-effectiveness. Evaluating performance specifications is essential to match your application needs. According to industry reports, optimal vacuum levels can significantly impact productivity. Certain applications prefer levels as low as 1 mbar. However, not all pumps achieve this efficiency.

When assessing vacuum pumps, focus on CFM ratings. A pump with a higher CFM efficiently moves air and maximizes throughput. If your application requires consistent operation, a pump with a robust motor may be necessary. Ensure the motor can handle prolonged use without overheating.

Consider the material used in the pump construction. The right material prevents corrosion, extending the pump’s lifespan. For example, stainless steel is often recommended for harsh environments. Avoid cost-cutting on materials; it can lead to premature failures.

Take time to reflect on your specific needs. Choosing a vacuum pump isn't one-size-fits-all. The wrong choice can lead to inefficiencies and dissatisfaction. Prioritize researching industry benchmarks and performance metrics for informed decisions.

Considering Noise Levels and Operating Environment

Choosing an industrial vacuum pump involves careful consideration of noise levels and the operating environment. Noise is often an overlooked factor. A pump might perform well but create a high level of noise, which can disrupt work. This is especially important in settings requiring focus or in environments where noise regulations are strict. Always check the decibel ratings. A quieter model can improve workplace comfort significantly.

The operating environment plays a crucial role. Dusty or wet conditions may require a more robust design. In some cases, pumps will need to be explosion-proof or resistant to chemicals. Consider the space available for the vacuum pump. Ensure it can be installed without overcrowding. Installing in tight or unsuitable spaces might lead to malfunctions. Evaluate maintenance access, too. Regular upkeep is essential for performance.

When evaluating options, reflect on how these factors balance with your needs. A vacuum pump that is perfect in one context may fail in another. Assessing your specific requirements can save time and money. Don't rush the decision. Take the time to gather feedback and analyze different models. What works best for one business may not be ideal for yours.

Assessing Maintenance and Service Requirements

When choosing an industrial vacuum pump, assessing maintenance and service requirements is crucial. A well-designed pump must be easy to maintain. Check whether the pump has accessible components for routine servicing. If not, it may lead to long downtimes. Regular inspections can identify small issues before they become significant problems.

Consider the availability of service technicians in your area. A lack of qualified service could hinder timely repairs. It's essential to evaluate if spare parts are easily obtainable. Some pumps may require specialized components, which can lead to delays. A proactive maintenance schedule is vital. It can extend the life of your pump.

Don't overlook the manufacturer’s support. They should provide clear guidelines for maintenance. An unclear manual can create confusion during service. This might affect efficiency and result in costly mistakes. Assessing these aspects is as important as the pump's specifications. Reflect on potential challenges before making a decision.

Budgeting for Initial Costs and Long-Term Investments

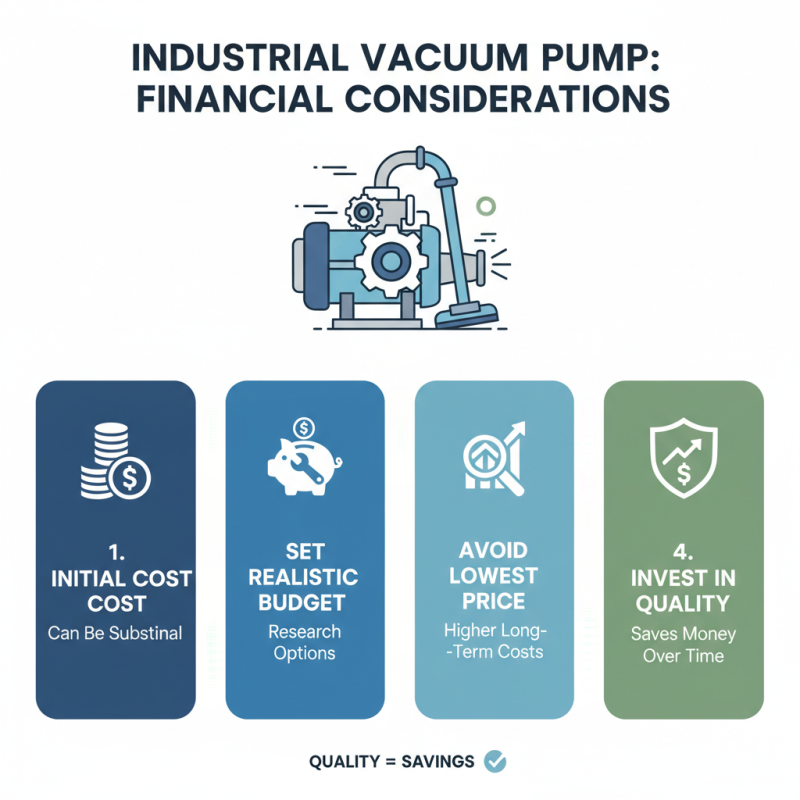

Choosing the right industrial vacuum pump involves significant financial considerations. Initial costs can be substantial. Thus, it's essential to set a realistic budget. Take your time to research various options. Avoid falling for the lowest price, as it may lead to higher long-term expenses. Invest a bit more upfront for quality.

Consider the long-term implications of your choice. An efficient pump can save you on maintenance. It might reduce energy costs over time as well. Understand that not all features are necessary. Delve into what fits your operations best.

Tip: Always evaluate the efficiency ratings. A more efficient pump can mean lower operational costs later on. Think about the environment too. Select a model that minimizes noise and vibration. These factors can impact your workspace. Reflect on how much you plan on using the pump. Will it serve a temporary project or be a long-term asset?

Related Posts

-

2026 Best Industrial Vacuum Pump Options for Your Needs?

-

Understanding the Importance of Proper Maintenance for Your Diesel Tank System

-

How to Choose the Right Gas Pump for Your Business Needs

-

How to Choose the Right Suction Pump for Your Industrial Needs

-

Unleashing the Power of Air Diaphragm Pumps: How They Revolutionize Fluid Handling in Various Industries

-

10 Essential Tips for Choosing the Right Gear Pump for Your Applications