Understanding the Role of Suction Pumps in Modern Industrial Applications and Their Efficiency Metrics

In the modern industrial landscape, suction pumps have become indispensable tools, significantly enhancing the efficiency and effectiveness of various applications, from construction to wastewater management. According to a report by Grand View Research, the global suction pump market was valued at approximately $4.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 3.5% from 2023 to 2030. This growth highlights the increasing reliance on suction pumps in critical sectors requiring reliable fluid handling solutions. Their ability to create a vacuum effect allows for the efficient transfer of liquids and slurries, contributing to improved operational productivity and reduced downtime. As industries adapt to evolving technological demands, understanding the performance metrics and optimal applications of suction pumps will be essential for engineers and operators aiming to leverage their full potential in contemporary industrial practices.

The Importance of Suction Pumps in Industrial Settings and Their Usage Statistics

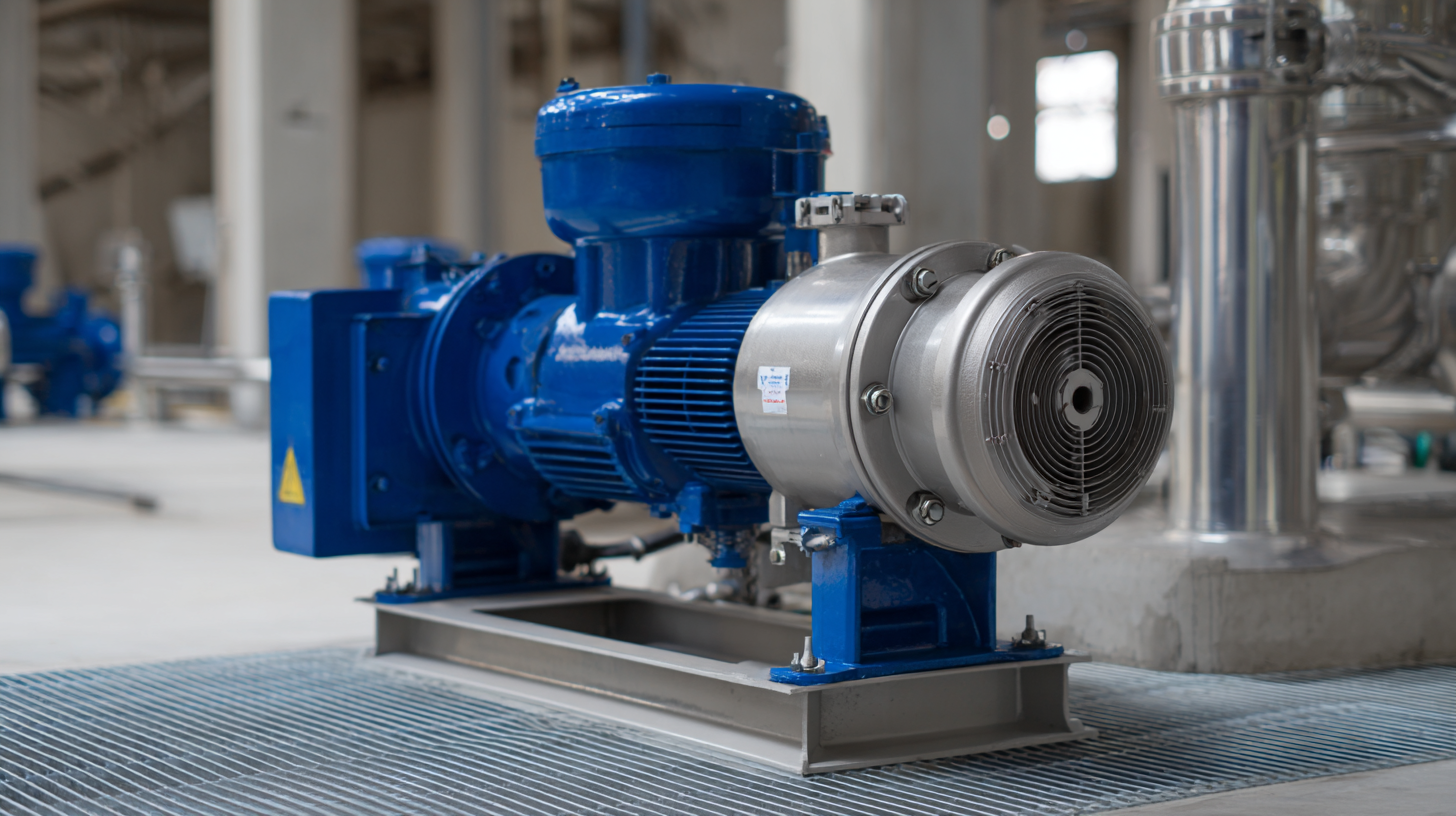

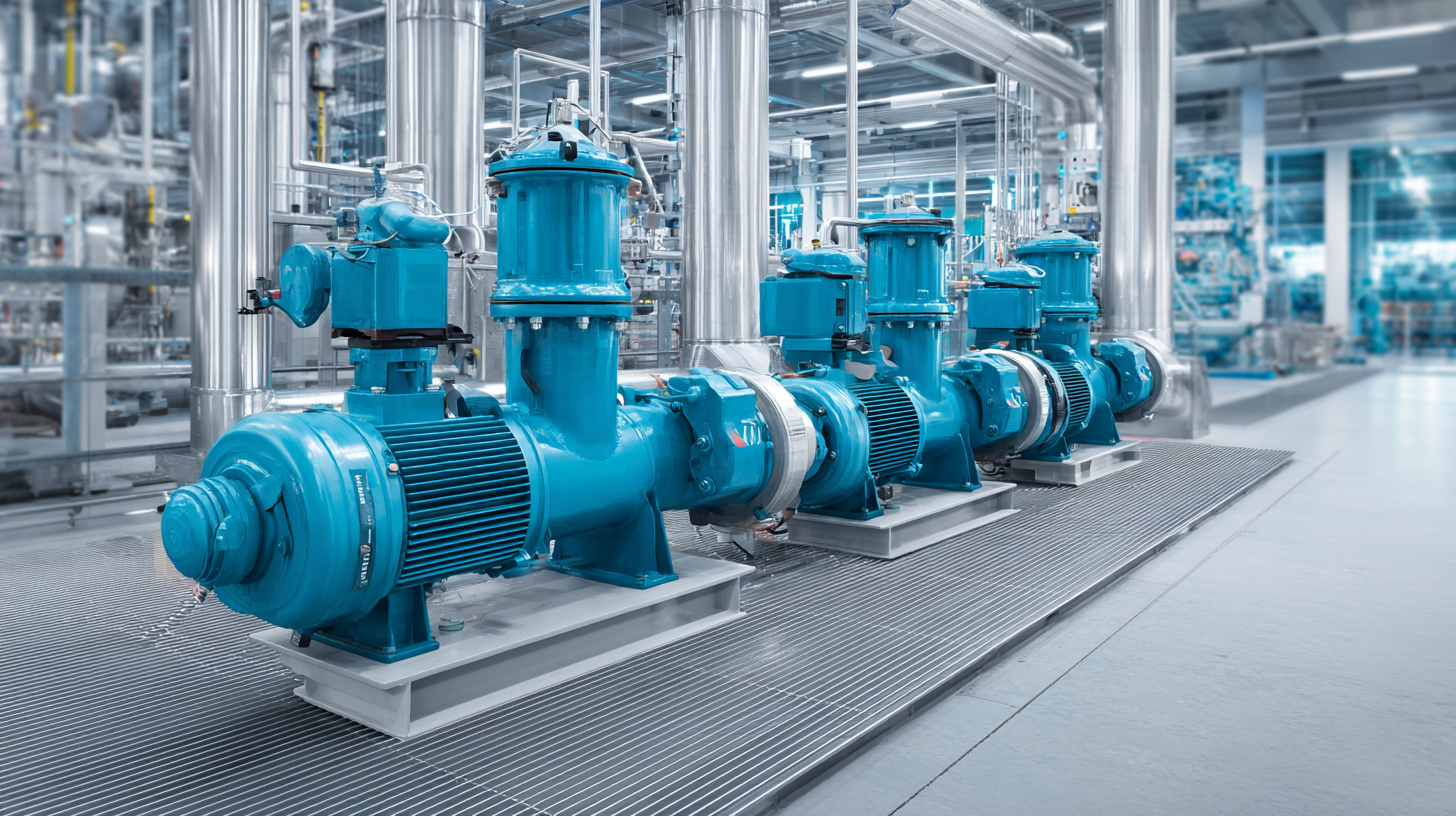

Suction pumps play a critical role in various industrial applications, significantly contributing to operational efficiency. These devices are designed to create a vacuum that enables the withdrawal of fluids and particulates from a designated area. In industries such as wastewater treatment, food processing, and manufacturing, suction pumps ensure the effective movement of liquids and sludges, thereby optimizing production processes and maintaining safety standards. This versatility showcases their essential nature across multiple sectors.

Usage statistics reveal that suction pumps account for a substantial percentage of equipment in industrial settings, with growth projected in the coming years. For instance, in the water treatment industry, a staggering amount of water is processed daily, and the efficiency of suction pumps directly impacts the overall system performance. Additionally, advancements in technology continue to enhance the efficiency metrics of these pumps, reducing energy consumption while increasing reliability and longevity. As industries strive for sustainable practices, the demand for advanced suction pump solutions that can handle diverse applications is higher than ever.

Understanding the Role of Suction Pumps in Modern Industrial Applications and Their Efficiency Metrics

| Application Area | Pump Type | Efficiency Metric (%) | Flow Rate (L/min) | Usage Percentage (%) |

|---|---|---|---|---|

| Chemical Processing | Positive Displacement | 85 | 150 | 30 |

| Water Treatment | Centrifugal | 90 | 200 | 25 |

| Food and Beverage | Diaphragm | 80 | 120 | 20 |

| Mining | Submersible | 88 | 300 | 15 |

| Pharmaceuticals | Peristaltic | 93 | 100 | 10 |

Key Efficiency Metrics for Evaluating Suction Pump Performance

When evaluating the performance of suction pumps in industrial applications, several key efficiency metrics come into play. One of the primary metrics is the pump's overall efficiency, which is defined as the ratio of the useful hydraulic energy delivered by the pump to the mechanical energy supplied to it. This efficiency is critical as it directly impacts energy consumption, operational costs, and overall system performance.

Another vital metric is the Net Positive Suction Head Available (NPSHa), which must exceed the Net Positive Suction Head Required (NPSHr) to avoid cavitation. Cavitation can severely damage the pump and reduce efficiency. Additionally, flow rate, typically measured in gallons per minute (GPM) or liters per second (L/s), is essential in determining how well a pump meets the demands of a given application. By analyzing these efficiency metrics, industries can optimize their suction pump operations, ensuring reliability and cost-effectiveness in their processes.

Innovative Technologies Enhancing Suction Pump Functionality

In recent years, innovative technologies have significantly enhanced the functionality of suction pumps, making them more efficient and versatile for various industrial applications. Features such as variable speed drives, smart sensors, and advanced materials are redefining how suction pumps operate. These enhancements not only improve the performance of pumps but also help reduce energy consumption, leading to lower operational costs.

Tips: When selecting a suction pump, consider the application requirements and the specific characteristics of innovative models. Look for features like real-time monitoring capabilities, as they can provide valuable data on pump performance and alert you to potential issues before they escalate.

Moreover, the integration of IoT technologies allows for better data management and predictive maintenance strategies. This empowers operators to make informed decisions about their systems, maximizing both reliability and efficiency. The ability to remotely monitor pumps ensures that any anomalies are detected early, further optimizing maintenance schedules and extending the lifespan of the equipment.

Tips: Regularly reviewing performance metrics can help identify trends and areas for improvement. Employing predictive analytics can further refine the operation of your suction pumps, ultimately enhancing their efficiency and reliability in industrial settings.

Common Applications of Suction Pumps Across Various Industries

Suction pumps play a pivotal role in a wide range of industrial applications, demonstrating their versatility across various sectors. In the oil and gas industry, for instance, suction pumps are employed to transport crude oil from extraction sites to refineries. According to a report by the International Energy Agency, the efficiency of suction pumps in these applications can reach up to 80%, significantly reducing operational costs compared to traditional transport methods.

In the manufacturing sector, suction pumps are instrumental in handling liquids, sludges, and even heavy materials. For example, in the food and beverage industry, they are utilized for transferring viscous substances like oils and sauces, where maintaining hygiene is crucial. A study by MarketsandMarkets indicates that the global suction pump market is projected to grow at a CAGR of 4.5% from 2021 to 2026, underscoring their increasing importance and application across diverse industries.

Furthermore, in the construction industry, suction pumps are essential for dewatering operations on construction sites, ensuring worker safety and project efficiency. With advancements in technology, modern suction pumps offer enhanced features, such as automated controls and energy-saving designs, leading to improved performance and lower energy consumption. The continuous evolution of suction pump technology ensures their relevance and effectiveness in meeting the complex demands of contemporary industrial operations.

Tips for Optimizing Suction Pump Efficiency and Reducing Downtime

Suction pumps play a crucial role in various industrial applications, emphasizing the need for efficiency and reliability. To optimize suction pump performance, operators should focus on regular maintenance, ensuring that components such as seals and filters are in good condition to prevent leaks and blockages. Additionally, the selection of the appropriate pump size for the specific application can significantly affect energy consumption and operational effectiveness.

Monitoring performance metrics like flow rate, pressure levels, and energy usage is essential for identifying potential issues before they lead to downtime. Implementing automated monitoring systems can aid in real-time analysis, allowing for timely adjustments and interventions.

With the projected growth in sectors such as solar water pumps and utility pumps in North America, companies must prioritize these optimization strategies to maintain a competitive edge while minimizing operational costs and maximizing efficiency.

Related Posts

-

How to Choose the Right Suction Pump for Your Industrial Needs

-

The Essential Guide to Choosing the Right Air Diaphragm Pump for Your Application Needs

-

Unlocking Efficiency: The Advantages of Advanced Fuel Storage Tanks for Your Business

-

How to Select the Right Chemical Pump for Your Industrial Needs

-

Efficient Fuel Transfer Tank Pump Solutions for Every Need

-

How to Choose the Right Double Diaphragm Pump for Your Application