How to Select the Right Centrifugal Pump for Your Industrial Applications

Choosing the appropriate centrifugal pump is critical for optimizing efficiency and performance in various industrial applications. According to the "Global Centrifugal Pump Market" report by MarketsandMarkets, the centrifugal pump market is projected to reach $40.5 billion by 2025, growing at a CAGR of 4.6% from 2020. This growth underscores the importance of selecting the right pump to reduce operational costs and enhance productivity.

Factors such as flow rate, fluid characteristics, and system requirements play vital roles in this selection process. With a multitude of options available, industries must navigate technical specifications and application suitability to ensure reliable and efficient pumping solutions.

Understanding these elements not only aids in minimizing maintenance costs but also contributes to sustainable operational practices.

Understanding Centrifugal Pump Operating Principles for Optimal Performance

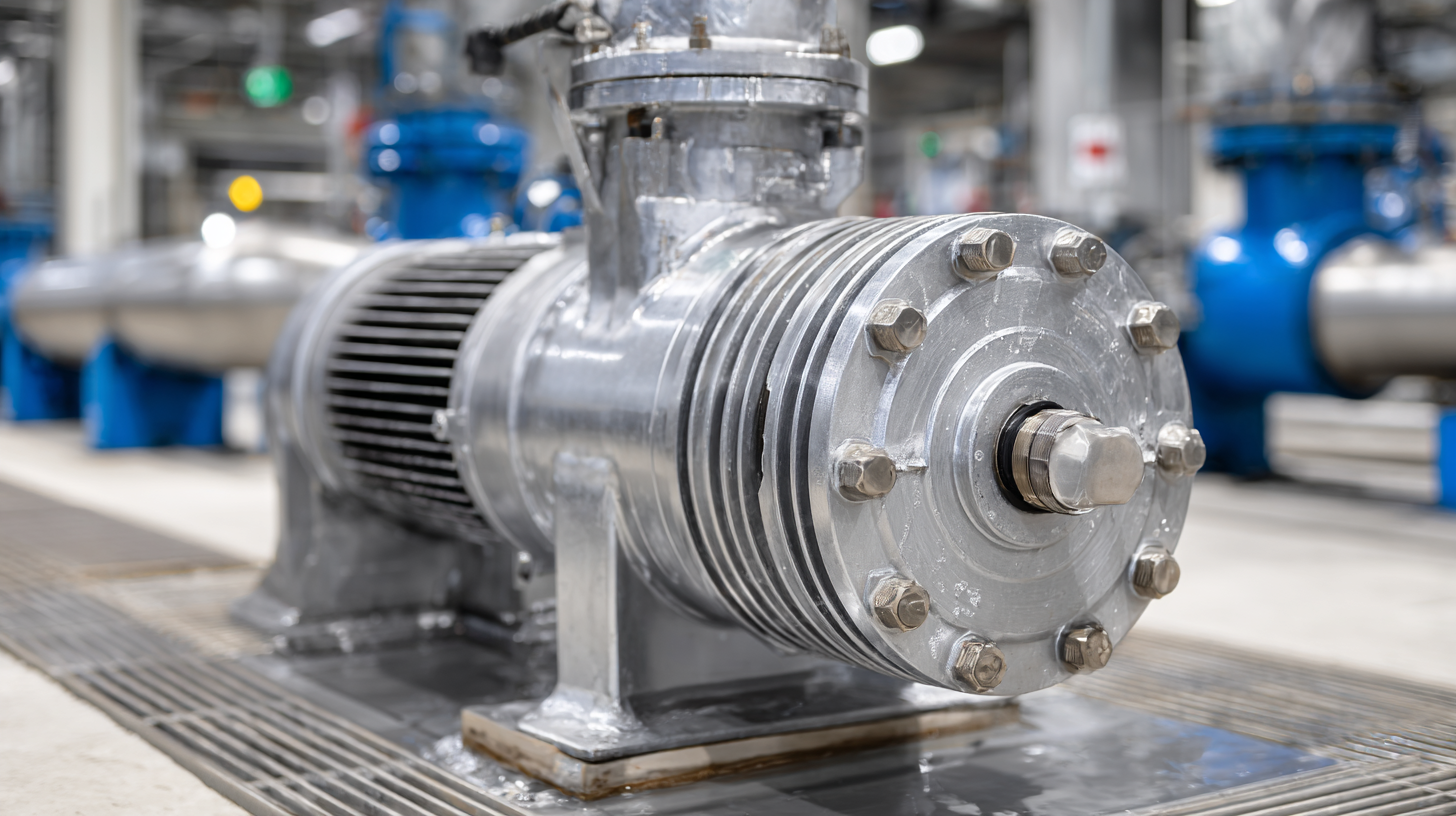

Centrifugal pumps are essential in various industrial applications due to their efficient movement of fluids. Understanding their operating principles is key to optimizing performance. At the core of a centrifugal pump's operation is its impeller, which rotates rapidly to impart kinetic energy to the fluid. This energy causes the fluid to move outward from the center of the impeller, converting kinetic energy into pressure. Thus, the design and material of the impeller play a crucial role in determining the pump's efficiency and suitability for specific fluids.

Another critical aspect is the pump's operating point, which is determined by the system's resistance and the pump's characteristic curve. Matching these two elements ensures optimal flow and pressure, preventing issues such as cavitation and excessive wear. Additionally, factors like fluid viscosity, temperature, and the presence of solids must be considered when selecting a pump. By thoroughly understanding these operating principles, industrial users can make informed decisions, ultimately enhancing the longevity and reliability of their pumping systems.

Key Factors in Determining Pump Capacity and Flow Rate Requirements

Selecting the right centrifugal pump for industrial applications hinges on understanding key factors that influence pump capacity and flow rate requirements. According to market research, the global industrial pumps market was valued at approximately USD 46.4 billion in 2024 and is projected to grow significantly, reaching USD 77.1 billion by 2034. This growth highlights the increasing demand for efficient and reliable pumping solutions across various industrial sectors.

One critical aspect when determining pump capacity is the specific application environment. For instance, the handling of sewage and wastewater necessitates pumps designed to manage solids and variable flow rates efficiently. Recent studies, such as the demand analysis from Custom Market Insights, reveal that the global sewage pump market is becoming increasingly robust, reflecting a growing need for specialized pumping equipment. Understanding the nature of the fluid—whether it’s viscous, contains solids, or has corrosive properties—is essential for selecting a pump that can maintain both optimal flow rates and energy efficiency.

Additionally, factors like the required flow rate, head height, and efficiency ratings must be evaluated meticulously. Optimal pump selection can lead to enhanced operational efficiency and reduced long-term costs. As the industrial sector continues to evolve, leveraging data-driven insights becomes crucial for selecting pumps that meet the burgeoning demands while ensuring performance and sustainability.

Evaluating Material Compatibility and Corrosion Resistance in Pump Selection

When selecting a centrifugal pump for industrial applications, one crucial aspect to consider is material compatibility and corrosion resistance. The pump's components must withstand the specific chemicals and operating conditions they will encounter to prevent failures or reduced efficiency over time. For instance, when handling acidic or caustic fluids, materials such as stainless steel or specialized alloys may be necessary to ensure longevity and reliability.

Tips for evaluating material compatibility include reviewing the chemical properties of the fluids involved and consulting with manufacturers about suitable materials. Understanding the environment where the pump will operate, including temperature and pressure conditions, is also essential for selecting the right materials. Moreover, consider the pump’s exposure to abrasive particles, which can accelerate wear and lead to premature failure if the wrong materials are chosen.

In addition to material compatibility, assess the pump's corrosion resistance features. Look for pumps with protective coatings or those designed to minimize corrosion through innovative engineering approaches. This will not only enhance the pump's lifespan but also improve overall system safety and efficiency in various industrial applications. Always remember that investing time and resources in proper pump selection can yield significant long-term benefits.

Assessing Energy Efficiency and Operating Costs for Long-term Savings

When selecting a centrifugal pump for industrial applications, energy efficiency and operating costs must be prioritized for long-term savings. According to the U.S. Department of Energy, pumps account for nearly 20% of the total industrial electricity consumption, making it essential to choose a pump that minimizes power usage while delivering optimal performance. Energy-efficient models can save facilities significant costs over time; a pump operating at 75% efficiency versus one at 55% can represent thousands of dollars in annual savings, especially in larger-scale operations.

**Tip:** Always consider the pump's efficiency curve, ensuring you select a model that operates close to its Best Efficiency Point (BEP) under your specific conditions. This not only boosts energy savings but also extends the pump's lifespan due to reduced mechanical stress.

Additionally, operational costs extend beyond energy consumption. Maintenance and repair expenses can significantly impact the total cost of ownership. The Hydraulic Institute report indicates that up to 70% of pump maintenance issues stem from improper selection and installation. Engaging with a knowledgeable supplier to assess your specific requirements can mitigate these risks.

**Tip:** Regularly scheduled maintenance and monitoring can prevent unexpected downtimes and costly repairs, so incorporate a thorough maintenance plan into your operational strategy for sustaining efficiency.

Choosing the Right Pump Design for Specific Industrial Applications and Conditions

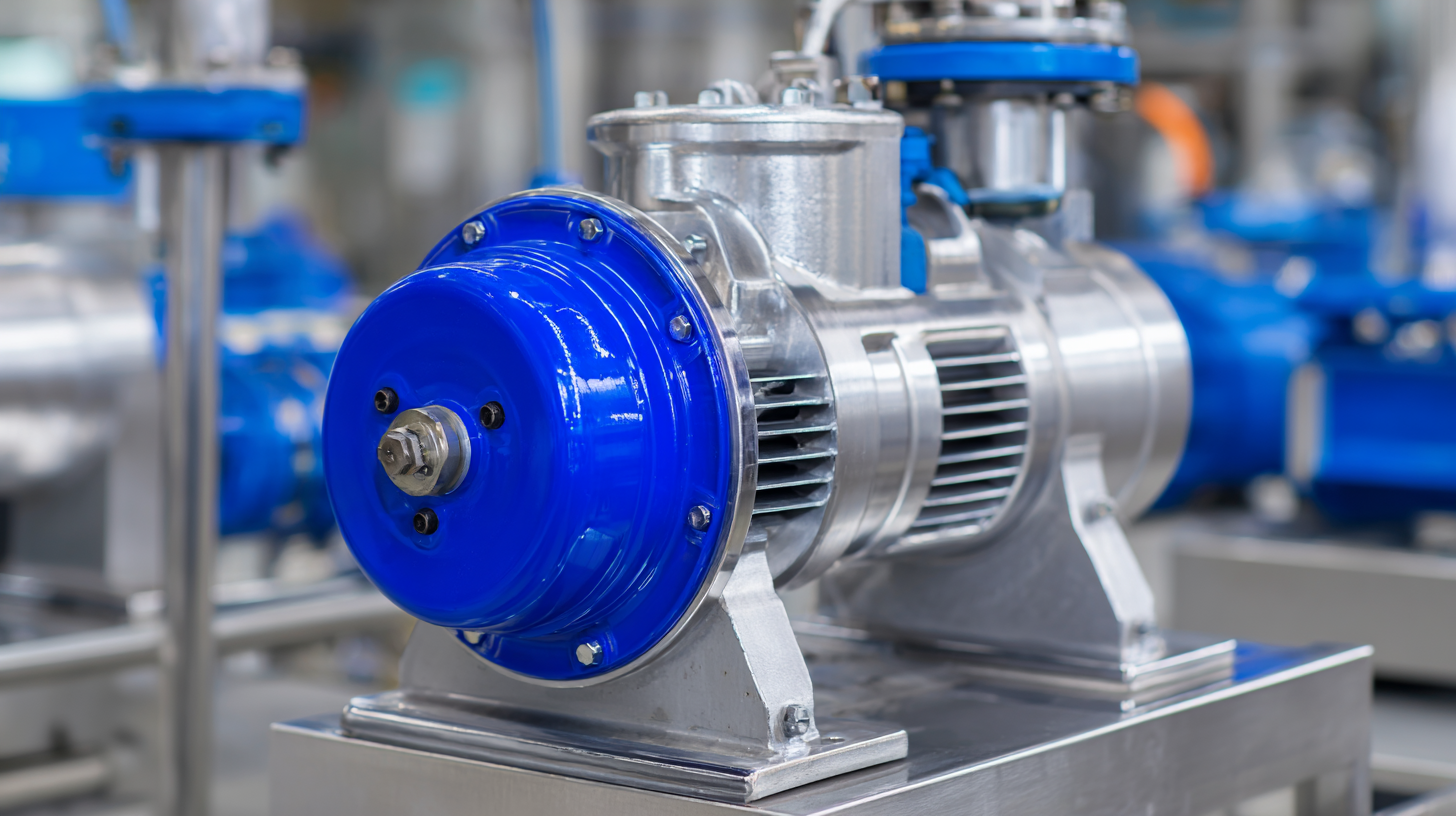

When selecting the right centrifugal pump for industrial applications, it is crucial to consider specific pump designs suited for varying operational conditions. According to the Hydraulic Institute’s 2022 report, nearly 70% of industrial processes rely on centrifugal pumps, emphasizing the importance of making informed choices. For applications involving high viscosity fluids, opting for a pump with a side-channel design can significantly enhance efficiency, offering better flow control and reduced maintenance needs.

Additionally, the operating environment plays a critical role in pump selection. For example, in applications with abrasive materials, such as those found in mining or wastewater treatment, using a centrifugal pump made from materials like hardened stainless steel or with a protective coating can prolong service life and minimize downtime. The American Society of Mechanical Engineers (ASME) suggests that the correct selection of material can reduce wear by up to 30%, leading to a more sustainable operation. By carefully assessing both the fluid characteristics and environmental conditions, industries can ensure they choose a centrifugal pump that meets their specific needs, ultimately improving performance and reliability.

How to Select the Right Centrifugal Pump for Your Industrial Applications

| Pump Type | Application | Flow Rate (GPM) | Head (ft) | Material |

|---|---|---|---|---|

| End Suction Pump | Water Supply | 50 | 60 | Cast Iron |

| Vertical Turbine Pump | Deep Well | 100 | 200 | Stainless Steel |

| Multistage Pump | High Pressure Applications | 25 | 300 | Bronze |

| Self-Priming Pump | Wastewater Management | 70 | 40 | Polypropylene |

| Chemical Pump | Chemical Processing | 40 | 100 | PTFE |

Related Posts

-

How to Choose the Right Suction Pump for Your Industrial Needs

-

Unlocking Efficiency and Cost Savings with Advanced Fuel Transfer Pump Solutions

-

How to Select the Right Chemical Pump for Your Industrial Needs

-

Mastering Dosing Pumps: A Step-by-Step Guide to Optimal Use and Maintenance

-

Unlocking Efficiency: The Advantages of Advanced Fuel Storage Tanks for Your Business

-

Progressive Cavity Pumps Exposed: A Comprehensive Comparison of Efficiency and Cost-Effectiveness