Maximizing Efficiency: The Ultimate Guide to Choosing the Right Diesel Transfer Pump for Your Needs

In the modern industrial landscape, the efficiency of fuel management systems is crucial for operational success, particularly in sectors heavily reliant on diesel fuel. According to a report by the Diesel Technology Forum, the diesel engine population is expected to reach over 36 million by 2025, underscoring the growing need for effective fuel transfer solutions.

The diesel transfer pump plays a pivotal role in this context, enabling seamless fuel transfer while minimizing wastage and enhancing safety. As businesses expand and fuel consumption increases, selecting the right diesel transfer pump becomes essential for optimizing workflow and reducing downtime.

With numerous options available on the market, understanding the specific requirements of your operations is key to maximizing efficiency and achieving cost-effectiveness. This guide aims to navigate you through the complexities of choosing the appropriate diesel transfer pump tailored to your needs, ensuring you make an informed decision that aligns with industry standards and your operational goals.

Understanding Diesel Transfer Pump Types and Their Applications

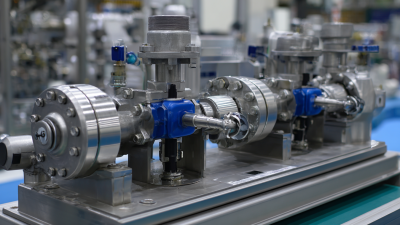

When selecting a diesel transfer pump, it's essential to understand the various types available and their specific applications. Positive displacement pumps are often favored for their ability to move diesel at high pressure, making them ideal for heavy-duty tasks such as refueling vehicles or large equipment. On the other hand, centrifugal pumps offer higher flow rates and are suitable for transferring diesel over longer distances or in bulk applications, providing efficiency for commercial operations.

In addition to pump types, you must consider the operational environment. Submersible pumps are designed for underground or tank installations, ensuring safe and effective fuel transfer without exposure to the elements. Portable options, like diaphragm pumps, provide flexibility for on-site operations, allowing users to easily move the pump where it’s needed most. Understanding these differences and the specific capabilities of each pump type will enable you to make an informed decision that aligns with your operational needs and enhances overall efficiency.

Maximizing Efficiency: The Ultimate Guide to Choosing the Right Diesel Transfer Pump for Your Needs

| Pump Type | Flow Rate (GPM) | Max Head (ft) | Typical Application | Power Source |

|---|---|---|---|---|

| Transfer Pump | 15 - 30 | 25 | Fuel Transfer | Electric or Diesel |

| Submersible Pump | 10 - 40 | 30 | Tank Emptying and Filling | Electric |

| Diaphragm Pump | 5 - 15 | 20 | Chemical Transfer | Air or Electric |

| Gear Pump | 10 - 25 | 15 | Oil Transfer | Electric or Hydraulic |

| Centrifugal Pump | 20 - 100 | 50 | High Volume Transfer | Electric or Diesel |

Key Performance Metrics: Flow Rate, Pressure, and Efficiency

When selecting a diesel transfer pump, understanding key performance metrics such as flow rate, pressure, and efficiency is crucial for optimizing operation. Flow rate, typically measured in gallons per minute (GPM), indicates how quickly the pump can move diesel fuel. Industry standards suggest that an efficient diesel transfer pump should achieve a flow rate of at least 20 GPM for mobile applications. According to a recent report by the Diesel Fuel Pump Manufacturers Association, pumps that operate within this range can significantly reduce downtime during fuel transfers, thus enhancing overall productivity.

Pressure is another critical factor that affects the effectiveness of a diesel transfer pump. It is essential to match the pump's pressure capabilities to the requirements of the specific application, whether it be for transferring fuel to equipment on construction sites or for refueling fleets. A study by FuelTech Insights shows that pumps operating with an optimal pressure range of 15 to 30 PSI can minimize leaks and ensure reliable performance during high-demand periods. This correlation between pressure and pump reliability underscores the importance of selecting a model that offers both adequate pressure and flow rate to meet operational needs efficiently.

Moreover, efficiency plays a pivotal role in long-term cost-effectiveness. A study from the National Association of Fuel Distributors indicates that high-efficiency pumps, defined as those converting at least 85% of engine power into transfer power, not only reduce energy consumption but also lower the total cost of ownership. Such pumps often have enhanced sealing technology and improved design features, which further minimize maintenance costs and enhance durability. Choosing the right diesel transfer pump, therefore, requires a thorough evaluation of these performance metrics to ensure maximum efficiency and reliability in fuel transfer operations.

Assessing Pump Compatibility with Various Diesel Storage Systems

When selecting a diesel transfer pump, compatibility with your existing diesel storage systems is crucial to ensure optimal performance and efficiency. Various factors, such as tank size, design, and location, can greatly impact the pump's effectiveness. For example, a submersible pump may be ideal for underground tanks, while a suction pump is better suited for above-ground storage. Understanding these compatibility issues can help you make an informed choice that maximizes your operational efficiency.

In addition to tank design, consider the type of diesel fuel being stored. Some pumps are specifically designed to handle biodiesel or ultra-low sulfur diesel, which may require different materials and construction to prevent corrosion or wear. Moreover, the flow rate of the pump should match the rate at which diesel is being dispensed, as faster pumps might not be suitable for all applications. By carefully assessing these compatibility factors, you can select a pump that not only meets your operational requirements but also enhances the overall functionality of your diesel storage system.

Cost-Effectiveness Analysis: Upfront Investment vs. Long-Term Savings

When considering the acquisition of a diesel transfer pump, a thorough

cost-effectiveness analysis is paramount.

Upfront investment is often the first consideration, with prices of quality diesel transfer pumps ranging from

$200 to over $4,000 depending on their capacity and features. According to a report

from the Diesel Pump Association, selecting a pump that meets your specific needs can save businesses up to

30% in operational costs over time by minimizing energy consumption and

reducing maintenance frequency.

Long-term savings should also be weighed alongside the initial cost. High-efficiency diesel transfer pumps can

deliver savings through reduced fuel expenses and labor costs associated with outdated models. For example,

businesses adopting modern, energy-efficient pumps can see

return on investment (ROI) within the first two years, primarily due to

decreased fuel wastage. Industry studies indicate that over the lifespan of the equipment, companies can save

as much as 50% in operational costs compared to traditional pumps,

highlighting the importance of considering long-term benefits over short-term expenditures.

Regulatory Compliance: Choosing Pumps That Meet Industry Standards

When selecting a diesel transfer pump, regulatory compliance is a crucial factor that cannot be overlooked. Many industries are governed by stringent regulations aimed at ensuring safety and environmental sustainability. According to a report from the American Petroleum Institute (API), over 65% of major spills in the oil and gas sector are directly linked to improper handling and transfer of fuels. This underscores the importance of choosing pumps that are designed and certified to meet relevant industry standards, such as those set by the Environmental Protection Agency (EPA) and Occupational Safety and Health Administration (OSHA).

Compliance with these regulations not only mitigates risks associated with fuel transfer but also enhances operational efficiency. A study from the National Institute of Standards and Technology (NIST) reveals that businesses adhering to regulatory standards can achieve up to a 30% increase in operational efficiency due to reduced downtime and improved safety practices. Therefore, investing in a diesel transfer pump that meets industry requirements is not merely a compliance issue; it is a strategic decision that can lead to significant long-term benefits, both financially and environmentally.

Maximizing Efficiency: Diesel Transfer Pump Types and Their Efficiency Ratings

This chart displays the efficiency ratings of various diesel transfer pump types based on industry standards. Each bar represents a different type of pump, showcasing their performance in terms of efficiency. Selecting the right pump according to these ratings can enhance operational productivity and ensure compliance with regulatory standards.

Related Posts

-

Top Strategies for Enhancing Efficiency with Metering Pumps

-

Exploring the Impact of Diesel Tank Innovations at the 138th Canton Fair 2025 in China

-

Understanding the Different Types of Vacuum Pumps and Their Applications

-

How to Choose the Right Gas Transfer Pump for Your Industrial Needs

-

Unlocking Efficiency and Cost Savings with Advanced Fuel Transfer Pump Solutions

-

7 Reasons to Choose a Diesel Transfer Tank with Pump for Your Business