Maximizing Efficiency and Safety with Diesel Transfer Tanks Featuring Pumps in the Fuel Industry

In the fast-paced and demanding fuel industry, maximizing efficiency and safety is paramount to ensuring smooth operations and minimizing downtime. According to a report by the National Petroleum Institute, over 70% of fuel transfer incidents are attributed to improper handling and storage, highlighting the need for reliable equipment like a diesel transfer tank with pump. These specialized tanks are designed not only to store diesel safely but also to facilitate controlled and efficient dispensing, which is critical in various applications from construction sites to agricultural operations.

Utilizing a diesel transfer tank with pump can significantly enhance the overall safety profile of fuel handling practices. The American Petroleum Institute emphasizes that using proper transfer equipment can reduce spill risks by as much as 40%. This statistic underscores the importance of investing in quality diesel transfer solutions that meet industry safety standards. Moreover, these tanks are equipped with advanced pumping systems that streamline the fueling process, decreasing the time spent on fuel transfers and allowing operators to focus on core business activities while ensuring compliance with regulatory requirements regarding fuel storage and handling.

Utilizing a diesel transfer tank with pump can significantly enhance the overall safety profile of fuel handling practices. The American Petroleum Institute emphasizes that using proper transfer equipment can reduce spill risks by as much as 40%. This statistic underscores the importance of investing in quality diesel transfer solutions that meet industry safety standards. Moreover, these tanks are equipped with advanced pumping systems that streamline the fueling process, decreasing the time spent on fuel transfers and allowing operators to focus on core business activities while ensuring compliance with regulatory requirements regarding fuel storage and handling.

In conclusion, as the fuel industry continues to evolve, the integration of efficient and safe fuel transfer equipment like diesel transfer tanks with pumps becomes increasingly crucial. By adhering to best practices and leveraging advanced technology, companies can safeguard their operations against potential hazards while optimizing productivity, ultimately leading to a more sustainable and profitable future in fuel management.

Understanding the Importance of Diesel Transfer Tanks in Fuel Efficiency

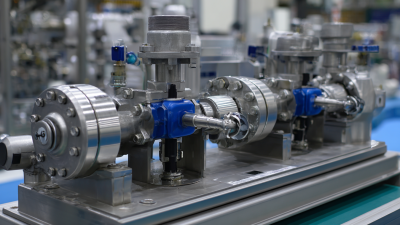

Diesel transfer tanks play a crucial role in enhancing fuel efficiency within the fuel industry. They are designed to store and transport diesel fuel safely while minimizing waste and spillage. By utilizing these tanks, companies can streamline their operations, ensuring that fuel is delivered where it's needed without unnecessary delays or losses. The integration of pumps in these systems further amplifies efficiency, allowing for quick and precise transfers that save both time and resources.

Moreover, the use of diesel transfer tanks ensures compliance with safety regulations, reducing the risk of accidents during fuel handling. These tanks are built with durable materials and features such as spill containment, which significantly mitigate environmental hazards. By prioritizing the safe transfer of diesel, businesses not only protect their workforce but also contribute to sustainable practices within the industry, ensuring that fuel efficiency is achieved without compromising safety standards.

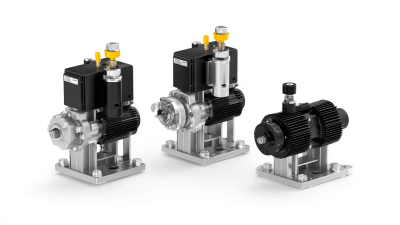

Key Features of Diesel Transfer Pumps for Enhanced Safety Standards

In the fuel industry, the use of diesel transfer tanks equipped with pumps has become essential for enhancing both efficiency and safety. One crucial feature of these pumps is the automatic shut-off mechanism, which prevents overfilling and potential spillage. This safety feature significantly reduces the risk of accidents, protecting not only the environment but also workers on-site.

Moreover, modern diesel transfer pumps often incorporate advanced filtration systems to ensure that the fuel is free from contaminants, which can lead to equipment failures and costly downtime. These filtration systems enhance the longevity of machinery and contribute to more reliable operations. Additionally, user-friendly interfaces and real-time monitoring capabilities provide operators with the ability to manage fuel transfers more effectively, ensuring compliance with safety standards and regulations in the fuel industry. Together, these key features contribute to safer and more efficient fueling operations, ultimately benefiting businesses in the sector.

Maximizing Efficiency and Safety with Diesel Transfer Tanks Featuring Pumps in the Fuel Industry

| Feature | Description | Benefit |

|---|---|---|

| Automatic Shut-off Valves | Prevents overfilling and spillage. | Enhances safety by reducing fuel loss and environmental impact. |

| Built-in Filtration Systems | Removes contaminants from the fuel before transfer. | Improves engine performance and reduces maintenance costs. |

| Digital Flow Meters | Measures the quantity of fuel dispensed accurately. | Ensures precise transactions and inventory tracking. |

| Emergency Stop Switches | Instantly halts the pumping process in emergencies. | Provides an added layer of safety for operators. |

| Portable Design | Easy to move and transport as needed. | Increases flexibility and convenience in operations. |

Reducing Downtime: The Economic Impact of Efficient Fuel Transfers

Efficient fuel transfer in the fuel industry is crucial for reducing downtime and enhancing economic productivity. The integration of diesel transfer tanks featuring pumps can streamline fuel delivery, ensuring that operations remain uninterrupted. This efficiency not only minimizes the time spent in refueling but also maximizes the availability of equipment and machinery, significantly impacting overall operational costs. In a market where just-in-time logistics are essential, having reliable fuel transfer systems can prevent delays that may ripple through the supply chain.

Moreover, as industries increasingly seek to adopt advanced technologies, the push for improved connectivity, such as through 5G, can further enhance the operational efficiency of fuel transfers. By providing real-time data and monitoring, firms can make informed decisions that optimize their fuel management systems. Ensuring that fuel is transferred swiftly and securely not only saves time but also reduces environmental impact, aligning with the broader goal of sustainable operation within the industry. As businesses focus on minimizing waste and enhancing productivity, the role of efficient fuel transfer becomes even more critical in shaping economic outcomes.

Industry Regulations: Compliance Requirements for Diesel Transfer Systems

In the fuel industry, adhering to industry regulations is crucial for the safe and efficient operation of diesel transfer systems. Compliance requirements are established to ensure that diesel transfer tanks and their associated pumps operate within safe parameters, protecting both personnel and the environment. Operators must be familiar with regulations set by agencies such as the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA), which mandate specific design, installation, and maintenance standards for fuel handling equipment.

Implementing these regulations involves regular inspections and adherence to proper safety measures, including spill containment and emergency shut-off systems. Furthermore, operators should prioritize training for personnel involved in fuel transfer operations, emphasizing the importance of following safety protocols and understanding the regulatory framework. By maintaining a rigorous compliance strategy, businesses can not only avoid legal pitfalls but also enhance operational efficiency and safety standards within the fuel industry.

Best Practices for Maintenance and Safety of Diesel Transfer Equipment

Proper maintenance and safety practices for diesel transfer equipment are essential for maximizing efficiency in the fuel industry. According to a report by the American Petroleum Institute (API), over 70% of diesel fuel spills occur due to improperly maintained equipment. Regular inspections, including checking for leaks, proper hose connections, and corrosion, can significantly mitigate risks associated with fuel transfer. Implementing a routine maintenance schedule can not only prevent accidents but also enhance the longevity of the transfer tanks and pumps, aligning with the industry’s goal of minimizing downtime.

Safety protocols must also be a cornerstone of the operational framework. According to the National Fire Protection Association (NFPA), almost 30% of all fuel-related incidents involve human error, often due to inadequate training or lack of adherence to safety guidelines. Training personnel in safe handling procedures, emergency response tactics, and the proper use of personal protective equipment (PPE) can drastically reduce the likelihood of accidents. By fostering a culture of safety and compliance, fuel industry operators can ensure that their diesel transfer operations remain efficient and secure, ultimately leading to a reliable service for their customers.

Maximizing Efficiency and Safety with Diesel Transfer Tanks

Bar chart representing the maintenance frequency and safety incidents related to diesel transfer equipment.

Related Posts

-

How to Choose the Right Fuel Transfer Tank with Pump for Your Needs

-

Understanding the Benefits of a Diesel Transfer Tank with Pump for Efficient Fuel Management

-

How to Choose the Right Air Operated Diaphragm Pump for Your Applications

-

Innovations in Fuel Storage Tanks Showcased at the 138th Canton Fair in 2025

-

Understanding the Importance of Proper Maintenance for Your Diesel Tank System

-

How to Choose the Right Gas Transfer Pump for Your Industrial Needs