Efficient Fuel Transfer Tank Pump Solutions for Every Need

In recent years, the demand for efficient fuel transfer tank pump solutions has surged, driven by the escalating need for reliable and effective fuel management systems across various industries. According to a report by Research and Markets, the global fuel transfer pump market is projected to grow at a compound annual growth rate (CAGR) of 4.5%, reaching approximately $2.5 billion by 2026. This growth is fueled by advancements in technology, regulatory changes, and the increasing prevalence of mobile fueling applications. A robust transfer tank pump is crucial for ensuring safe, timely, and economical fuel transfer, thus enhancing productivity while minimizing environmental impact. Furthermore, with the advent of smart technologies, the integration of IoT capabilities into transfer tank pumps has become a game-changer, allowing for real-time monitoring and management of fuel operations. As industries continue to optimize their fuel transfer processes, selecting the right transfer tank pump solution tailored to specific needs becomes imperative for operational efficacy and sustainability.

Choose the Right Fuel Transfer Pump for Your Specific Application

Choosing the right fuel transfer pump for your specific application is crucial to ensure efficiency and reliability in your operations. Different industries and tasks have unique requirements, and selecting a pump that aligns with these needs can optimize performance. Whether it's for agricultural use, construction, or transportation, understanding the distinct features and capabilities of various pump types can lead to better operational outcomes.

In North America, the utility pump market is projected to reach a value of $2.14 billion by 2024, with growth expected to continue to $2.23 billion in 2025 and to $3.04 billion by 2032. This expanding market underscores the increasing demand for efficient fuel transfer solutions tailored to diverse applications. Users should consider factors such as flow rate, portability, and compatibility with different fuel types when making their selection, ensuring that they invest in a pump that meets their specific operational demands.

Key Features to Consider When Selecting a Fuel Transfer Tank Pump

When selecting an efficient fuel transfer tank pump, several key features should be considered to ensure optimal performance for your specific needs. First, assess the pump's flow rate and compatibility with various fuel types, as this will determine how quickly and effectively you can transfer fuel. Moreover, durability is crucial; pumps constructed from materials that can withstand corrosive substances are essential, particularly for those considering alternative fuels like vegetable oil.

When selecting an efficient fuel transfer tank pump, several key features should be considered to ensure optimal performance for your specific needs. First, assess the pump's flow rate and compatibility with various fuel types, as this will determine how quickly and effectively you can transfer fuel. Moreover, durability is crucial; pumps constructed from materials that can withstand corrosive substances are essential, particularly for those considering alternative fuels like vegetable oil.

It's also vital to consider the pump's capacity and whether it can accommodate your fuel storage needs. For instance, marine fuel pumps are projected to grow significantly, with a market value expected to increase from $1.25 billion in 2025 to $1.7 billion by 2032, driven by the shift towards alternative fuels. This highlights the increasing demand for specialized pumping solutions.

Tips: When choosing a fuel transfer pump, prioritize models with built-in safety features such as automatic shut-off valves to prevent spills. Additionally, investigate models that offer energy-efficient operation, as this can significantly reduce costs and environmental impact over time. Lastly, always check for warranties and customer support options to protect your investment.

How to Ensure Safe and Efficient Fuel Transfer: Best Practices

Efficient fuel transfer is critical in industries ranging from transportation to agriculture, where diesel and other fuels are essential for operations. According to the American Petroleum Institute (API), improper fuel transfer can lead to significant losses, with estimates suggesting that inefficient systems result in up to 10% fuel waste annually. To mitigate these costs, organizations need to adopt best practices for safe and efficient fuel transfer.

First and foremost, utilizing high-quality fuel transfer tank pumps is vital. Reports by the National Association of State Fire Marshals indicate that over 30% of fuel transfer incidents involve equipment failure due to poor maintenance. Regular inspections and adherence to manufacturer guidelines can ensure that pumps operate at optimal efficiency. Furthermore, implementing measures such as automatic shut-off valves and overfill protection can prevent spills and enhance safety during fuel transfer operations, addressing both environmental and economic concerns.

Training personnel on the correct procedures for fuel handling is equally important. The Occupational Safety and Health Administration (OSHA) underscores the necessity of education in reducing workplace hazards, indicating that informed employees can cut risk incidents by up to 60%. By fostering a culture of safety through training and investing in modern pumping technology, businesses can significantly enhance their fuel transfer efficiency and safety standards.

Efficient Fuel Transfer Tank Pump Solutions for Every Need - How to Ensure Safe and Efficient Fuel Transfer: Best Practices

| Pump Type | Flow Rate (GPM) | Max PSI | Power Source | Applications |

|---|---|---|---|---|

| Electric Transfer Pump | 20 | 30 | Electric | Diesel, Oil Transfer |

| Hand-Held Pump | 5 | N/A | Manual | Gasoline, Oil Transfer |

| Fuel Transfer Pump | 15 | 40 | Gasoline | Diesel, Kerosene |

| Submersible Pump | 25 | 60 | Electric | Bulk Fuel Transfer |

| Diaphragm Pump | 10 | 50 | Pneumatic | Chemical Handling |

Maintenance Tips for Extending the Life of Your Fuel Transfer Pump

Proper maintenance of fuel transfer pumps is crucial for ensuring longevity and optimal performance. According to a recent industry report by the National Association of Fuel Distributors, regular maintenance can extend the life of these pumps by 30% or more. One essential practice is to regularly inspect and replace fuel filters, as clogged filters can lead to decreased efficiency and potential pump failure. Keeping the pump clean and free from contaminants not only enhances performance but also minimizes wear on internal components.

Another vital maintenance tip is to monitor the pump’s operational parameters, such as pressure and flow rates. The American Petroleum Institute recommends implementing a routine calibration schedule to ensure that your pump operates within its designated specifications. This practice helps identify potential issues early on, preventing costly repairs down the line. Additionally, lubricating moving parts according to manufacturer recommendations can significantly reduce friction and wear, contributing to an extended service life. By following these maintenance tips, operators can maximize the efficiency and reliability of fuel transfer pumps, ultimately leading to reduced operational costs and enhanced safety in their fuel transfer processes.

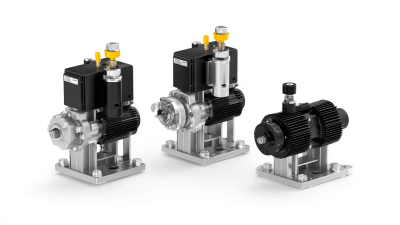

Comparing Electric vs. Manual Fuel Transfer Pumps: Which is Right for You?

When it comes to fuel transfer pumps, the choice between electric and manual options can greatly influence efficiency and convenience. Electric fuel transfer pumps are designed for ease of use, often requiring just the push of a button to start. They are typically faster, delivering fuel at a higher rate than their manual counterparts, which makes them ideal for larger jobs or frequent refueling tasks. For instance, an electric pump available on the market is highlighted for its user-friendly design and affordable price, making it a popular choice among users looking for a reliable solution.

On the other hand, manual fuel transfer pumps offer a different set of advantages. They are generally more portable and do not rely on electric power, making them suitable for remote locations or situations where electricity isn't readily available. Manual pumps require physical effort to operate, which can be a downside for some but can also serve as a practical solution in emergencies. The best choice for you will depend on specific needs, such as fuel transfer frequency, location, and personal preference regarding the level of exertion and convenience desired.

Related Posts

-

How to Choose the Right Chemical Pump for Your Industry Needs

-

How to Choose the Right Double Diaphragm Pump for Your Application

-

How to Choose the Right Gas Transfer Pump for Your Industrial Needs

-

Top Strategies for Enhancing Efficiency with Metering Pumps

-

Exploring the Impact of Diesel Tank Innovations at the 138th Canton Fair 2025 in China

-

How to Choose the Right Air Operated Diaphragm Pump for Your Applications