What is a double diaphragm pump and how does it work?

A double diaphragm pump is a specialized device widely used in various industries. Its design features two diaphragms that work in unison. This pump operates through simple yet effective mechanics. The two diaphragms create a suction effect, drawing fluid into the pump chamber. Then, they push the fluid out with strong pressure.

This pump's ability to handle diverse fluids makes it valuable. It can manage thick, abrasive, or corrosive materials. Many manufacturing facilities rely on the double diaphragm pump for efficiency. However, users need to understand its limitations. Regular maintenance is crucial to prevent breakdowns. Neglecting this can lead to performance issues.

Understanding the inner workings of a double diaphragm pump enhances its application. It's essential for operators to familiarize themselves with potential challenges. While the pump is generally reliable, unexpected situations may arise. Proper training and awareness of these factors are vital for optimal performance.

What is a Double Diaphragm Pump: Definition and Key Features

A double diaphragm pump is a versatile device used for moving fluids. It is designed with two flexible diaphragms that work in tandem. When one diaphragm expands, the other contracts, creating a suction effect. This design allows for efficient transfer of various liquids, from water to thicker substances.

Key features include the pump's ability to handle solids. The alternating motion of the diaphragms makes it effective for slurries and viscous liquids. The pump is also self-priming. This means it can start pumping without needing to fill the casing with liquid first. Some users, however, find the maintenance of such pumps can be complex. Cleaning and replacing diaphragms requires attention, which may lead to unexpected downtime.

The operation is relatively noisy compared to other pumps, which can be a concern in quieter environments. Users must also consider that not all double diaphragm pumps are suitable for every application. Each application requires careful assessment. Finding the right pump for specific needs can be challenging.

Double Diaphragm Pump Performance Characteristics

This chart illustrates key performance characteristics of a typical double diaphragm pump, including flow rate, maximum pressure, diaphragm life, and weight. Such data represents the efficiency and durability of double diaphragm pumps in various applications.

Principle of Operation: Understanding the Mechanism of Double Diaphragm Pumps

Double diaphragm pumps are versatile devices widely used in various industries. Understanding their mechanism reveals how they operate efficiently. These pumps utilize two flexible diaphragms, which create alternating suction and discharge phases. When one diaphragm moves down, it forces fluid out while the other retracts, drawing in more fluid. This cycle continues, maintaining a steady flow.

Data from industry reports indicates that double diaphragm pumps can handle a wide range of viscous and abrasive fluids. They are often employed in the chemical, food, and pharmaceutical sectors. The design allows for self-priming, which enhances efficiency.

However, it’s vital to monitor wear on diaphragms; failure can lead to leaks. Regular inspections are essential to avoid downtime.

Moreover, double diaphragm pumps are air-operated, which can introduce challenges. They require compressed air to function, making energy efficiency a concern. In some scenarios, they may also produce pulsation in the flow, which can affect system performance. Understanding these limitations is crucial for optimizing their use in any application.

Applications of Double Diaphragm Pumps in Various Industries

Double diaphragm pumps are increasingly popular in various industries due to their versatility and reliability. These pumps can handle both thick and abrasive fluids, making them ideal for environments such as construction and mining. According to a recent industry report, the global diaphragm pump market is expected to grow by 6.8% annually through 2027. This growth reflects the rising demand for efficient fluid transfer solutions.

In the environmental sector, double diaphragm pumps play a crucial role in wastewater treatment. Their ability to manage slurries and viscous materials allows for effective pollutant removal. A study showed that wastewater treatment facilities utilizing these pumps reduced their operational costs by up to 20%. Additionally, in the food and beverage industry, these pumps ensure hygienic transport of liquids. They minimize contamination risks, which is vital for meeting sanitation standards.

Despite their advantages, some challenges remain. Users sometimes report issues with maintenance and seal wear. Regular oversight is necessary to avoid leaks and ensure optimal operation. Furthermore, the pumps can be sensitive to certain chemicals, which may limit their application in certain cases. These factors contribute to ongoing discussions about improving diaphragm pump designs.

Advantages of Double Diaphragm Pumps Over Other Pump Types

Double diaphragm pumps are unique in their design and function. They utilize two diaphragms to create a pumping action. This leads to several advantages over other pump types. One key advantage is their ability to handle a variety of fluids, including viscous and abrasive materials. They offer great versatility where standard pumps may not perform well.

When considering a double diaphragm pump, think about maintenance. They require less frequent servicing compared to other pumps. This can save time and reduce operational costs. Additionally, their design allows for dry running and self-priming, which can enhance efficiency in many applications.

Tip: Always check the material compatibility of your pump. Not all materials will work with every fluid. It's essential to avoid costly damage or malfunction.

Another benefit is safety. Double diaphragm pumps minimize the risk of leaks. Their design helps in containing fluids, which is crucial for hazardous applications. This safety feature can protect both workers and the environment.

Tip: Regularly inspect your pump for signs of wear. Even minor issues can lead to significant problems later. Keeping an eye on your pump can help you avoid downtime and costly repairs.

These pumps may not be suitable for every scenario, but they are a solid choice in many contexts. Investing time in understanding their capabilities can lead to better operational decisions.

What is a double diaphragm pump and how does it work? - Advantages of Double Diaphragm Pumps Over Other Pump Types

| Feature | Double Diaphragm Pump | Other Pump Types |

|---|---|---|

| Design | Uses two diaphragms for pumping | Varies by type (centrifugal, gear, etc.) |

| Operation | Positive displacement mechanism | May use centrifugal force or other methods |

| Fluid Types | Handles viscous and shear-sensitive fluids | Best for low viscosity fluids |

| Maintenance | Low maintenance due to simple design | Maintenance varies widely by type |

| Applications | Ideal for chemical, food, and pharmaceutical industries | Widely used in water supply, heating, and more |

| Efficiency | High efficiency across various flows | Efficiency may decrease with fluid viscosity |

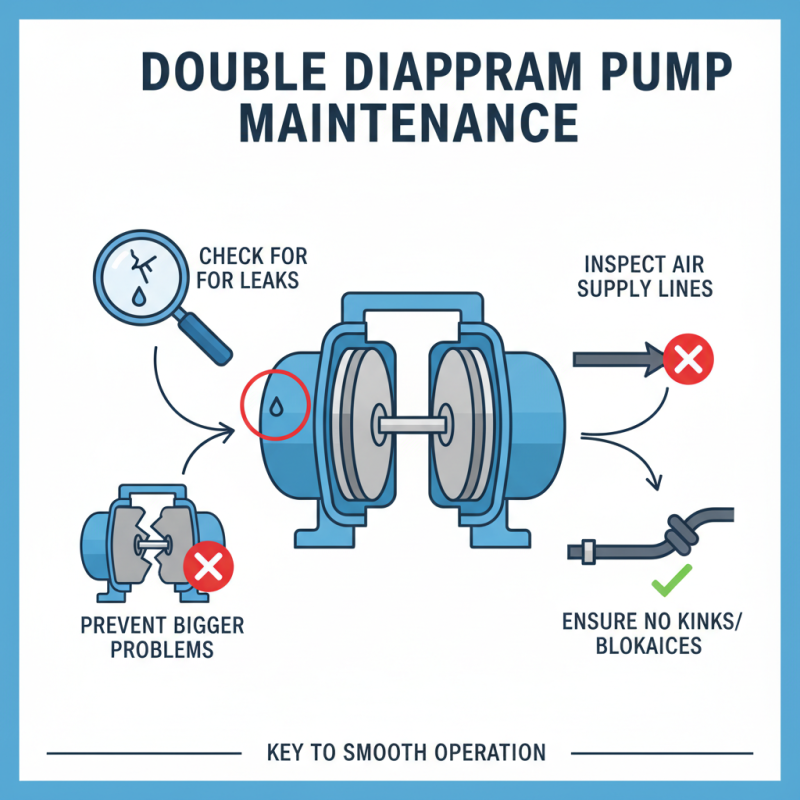

Maintenance and Troubleshooting Tips for Optimal Pump Performance

A double diaphragm pump is a useful tool in various industries. To keep it running smoothly, regular maintenance is key. Check for leaks around the diaphragm. A small leak can lead to bigger problems. Also, inspect the air supply lines. Ensure there are no kinks or blockages, as this affects performance.

Here are some tips to maintain your pump effectively. Clean the filters regularly to prevent debris buildup. Blockages can cause the pump to work harder, leading to wear. Another good tip is to lubricate moving parts. Proper lubrication helps reduce friction, which can extend the pump's lifespan. Don’t forget to check the valve condition periodically. Worn-out valves can lead to inefficiencies.

Troubleshooting is also an essential part of maintaining your pump. If the pump is not functioning as expected, listen for unusual noises. This can indicate a problem. Be mindful of the pressure gauge reading. Lower than normal pressure might signal an issue with the diaphragm. Address any concerns quickly to avoid costly repairs later.

Related Posts

-

2026 Best Double Diaphragm Pump Reviews and Buying Guide?

-

How to Select the Right Diaphragm Pump for Your Industrial Needs

-

How to Choose the Right Double Diaphragm Pump for Your Application

-

How to Select the Right Chemical Pump for Your Industrial Needs

-

How to Choose the Right Air Operated Diaphragm Pump for Your Applications

-

How to Choose the Right Chemical Pump for Your Industry Needs