How to Choose the Right Vacuum Pump for Your Needs: A Complete Guide

When it comes to selecting the right vacuum pump for your specific needs, understanding the various types, functions, and applications is essential. Expert in the field, Dr. Emily Carter, emphasizes the importance of making an informed decision: “Choosing the right vacuum pump can significantly impact the efficiency of your processes and lead to better outcomes.” With the wide array of vacuum pumps available today, from rotary vane to diaphragm pumps, it can be overwhelming to navigate the complexities involved.

This guide aims to simplify the selection process by providing insights into the key factors you should consider, including the applications, required vacuum levels, and maintenance practices. Understanding these elements will not only help you choose the most suitable vacuum pump but also enhance the overall productivity of your operations. Whether you are working in industrial, laboratory, or commercial settings, making the right choice is critical in achieving optimal performance and reliability.

Understanding Different Types of Vacuum Pumps and Their Applications

When selecting a vacuum pump, understanding the various types available and their specific applications is crucial. Vacuum pumps generally fall into three categories: positive displacement, momentum transfer (or molecular), and entrapment pumps. Positive displacement pumps, such as rotary vane and diaphragm pumps, are commonly used in laboratory environments and industrial applications where moderate vacuum levels are required, typically achieving pressures around 1 mbar. Reports show that this category dominates the market due to their reliability and versatility.

On the other hand, momentum transfer pumps, like diffusion and turbo pumps, are used for high and ultra-high vacuum applications, reaching pressures as low as 10^-9 mbar. These pumps are crucial in sectors such as semiconductor manufacturing and research laboratories, where ultra-clean environments are essential. A recent industry analysis revealed that the momentum transfer segment is expected to grow at a CAGR of 5.2%, driven by increasing demand for high-tech applications.

**Tips:** When choosing a vacuum pump, consider the specific requirements of your application, including the desired vacuum level and the nature of the gases being evacuated. Additionally, ensure that the pump's compatibility with your system is assessed to avoid potential operational inefficiencies. Lastly, keep an eye on maintenance needs, as some pumps require more regular servicing than others, impacting long-term operational costs.

How to Choose the Right Vacuum Pump for Your Needs: A Complete Guide

| Type of Vacuum Pump | Application | Advantages | Disadvantages |

|---|---|---|---|

| Positive Displacement Pump | Environmental Testing | Consistent Pressure | Limited Speed |

| Rotary Vane Pump | Industrial Vacuum Systems | Good Efficiency | Requires Maintenance |

| Diaphragm Pump | Laboratory Applications | Chemically Resistant | Lower Flow Rate |

| Scroll Pump | Semiconductor Industry | Low Noise Operation | Higher Initial Cost |

| Turbomolecular Pump | High Vacuum Applications | Extremely High Efficiency | Sensitive to Back Pressure |

Key Factors to Consider When Selecting a Vacuum Pump for Your Needs

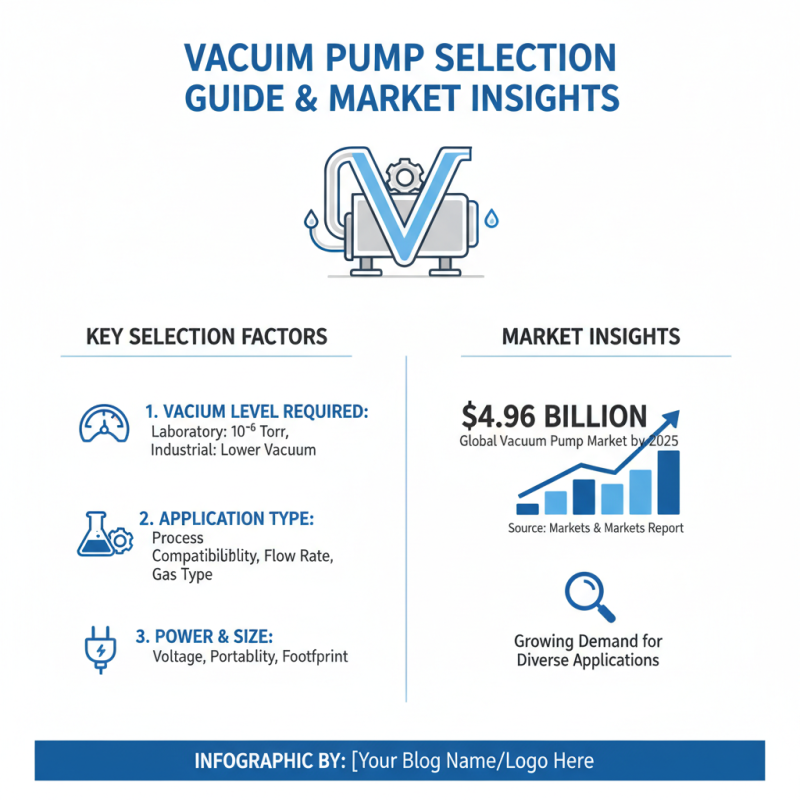

When selecting a vacuum pump, several key factors come into play that can significantly impact its performance and suitability for your specific applications. First and foremost, understanding the required vacuum level is essential. Different applications demand varying levels of vacuum; for instance, laboratory applications might require a high vacuum level of 10^-6 torr, while industrial uses may operate effectively at a lower level. According to the Vacuum Technology market report by Markets and Markets, the global vacuum pump market is projected to reach $4.96 billion by 2025, indicating a growing demand for pumps tailored to diverse application needs.

Another crucial factor is the pump's capacity and speed, typically measured in liters per minute (LPM) or cubic feet per minute (CFM). It's important to choose a pump that can handle the volume of gas or vapor you intend to evacuate to maintain efficiency. The American Vacuum Society suggests determining the total volume of the system and the rate at which it needs to be evacuated to select the appropriate pump sizing. In addition, consider the type of gases or vapors being handled, as some pumps are optimized for specific substances and may not perform effectively outside their intended applications, thus affecting operational costs and efficiency.

Additionally, maintenance requirements and ease of use should not be overlooked. Certain vacuum pumps require more frequent servicing or specialized skills, which can lead to increased downtime and operational costs. An annual review published by The Vacuum Solutions Institute highlights that minimizing maintenance through proper selection can reduce costs by approximately 20-30%, reinforcing the need for a careful evaluation of the pump's design and reliability. By thoroughly assessing these factors, users can ensure they select the right vacuum pump that aligns with their operational needs and enhances overall productivity.

Performance Metrics: CFM, Vacuum Level, and Energy Efficiency Explained

When choosing the right vacuum pump, understanding key performance metrics is essential. CFM (Cubic Feet per Minute) is a vital measure of the pump's air-moving capacity. High CFM ratings indicate a pump that can efficiently evacuate air from a larger space in a shorter time, which is particularly important in industrial applications where time is money. According to industry standards, a good vacuum pump should achieve the required CFM based on the volume of air it needs to remove and the operational conditions.

Vacuum level is another critical factor. It is usually measured in inches of mercury (inHg) or millibar, reflecting how much air has been removed from a specific volume. Generally, a higher vacuum level indicates better performance, allowing for applications that require deeper vacuum levels, such as freeze drying or scientific experiments. Various studies suggest that achieving vacuum levels below 27 inHg is necessary for high-end applications, making it essential to factor this into your selection process.

Tips: Always assess your application requirements before making a decision. Evaluate how much CFM you truly need based on the size of your workspace and the speed of operation required. Additionally, consider the energy efficiency of the pump, as this can significantly impact operational costs. Pumps with higher energy efficiency ratings often pay for themselves in savings over time, making them a more economical choice in the long run.

Comparing Cost vs. Quality: Investing in the Right Vacuum Pump

When considering a vacuum pump, it is crucial to balance cost and quality to ensure that you’re making a wise investment. While it might be tempting to opt for a cheaper model, lower upfront costs often lead to higher expenses down the line due to frequent repairs and replacements. Quality pumps, although more expensive initially, tend to offer better reliability, efficiency, and longevity, ultimately saving you money in the long run.

Tips for selecting the right vacuum pump include evaluating your specific needs in terms of application, volume, and required pressure level. Make sure to research the materials and technology used in the pump, as this affects both performance and durability. Additionally, consider the availability of parts and customer support, as these factors can greatly influence your overall ownership experience.

Another vital aspect to consider is the total cost of ownership. This includes not just the initial purchase price but also operational costs such as energy consumption, maintenance, and downtime. A more efficient, higher-quality pump can often reduce these operational costs significantly over time. Taking the time to weigh these factors will empower you to choose a vacuum pump that best fits your needs and budget, ensuring you have a reliable tool for years to come.

Vacuum Pump Cost vs. Quality Analysis

This chart illustrates the average cost of vacuum pumps based on their quality levels. As shown, low-quality vacuum pumps average around $150, while medium-quality pumps rise to $300, and high-quality options can reach $600. Choosing the right vacuum pump involves evaluating both cost and quality to meet specific operational needs.

Industry Standards and Regulations for Vacuum Pump Selection

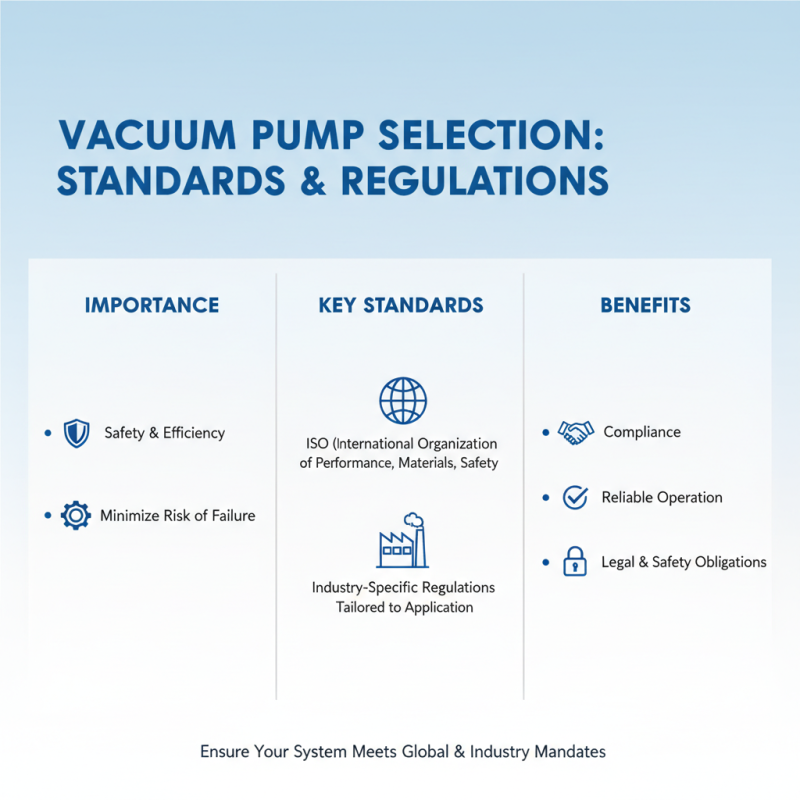

When selecting a vacuum pump, adhering to industry standards and regulations is crucial. These guidelines ensure that the vacuum systems operate safely and efficiently, minimizing the risk of failure. Key standards, such as those set by the International Organization for Standardization (ISO) and various industry-specific regulations, dictate essential performance criteria, materials compatibility, and safety measures. Understanding these requirements will help you choose a pump that meets not just operational needs but also legal and safety obligations in your industry.

Tips for selecting the right vacuum pump include consulting the latest industry standards pertinent to your application. Always verify that the vacuum pump meets the specified quality assurances and certifications. Additionally, consider the environment in which the pump will be operating—will it handle corrosive materials, or must it work under extreme temperatures? Aligning your selection with these regulatory frameworks will lead to long-term reliability and compliance, safeguarding your operations.

It's also beneficial to review any applicable local regulations that may affect your choice. For example, certain industries may have stricter emission controls or require specific safety features to protect workers. Engaging with professionals or consulting with technical experts can provide valuable insights into navigating these regulations effectively, ensuring that your decision-making process aligns with both operational and compliance needs.

Related Posts

-

Understanding the Different Types of Vacuum Pumps and Their Applications

-

Exploring the Impact of Diesel Tank Innovations at the 138th Canton Fair 2025 in China

-

7 Reasons to Choose a Diesel Transfer Tank with Pump for Your Business

-

Top 10 Best Fuel Storage Tanks for Safe and Efficient Use in 2023

-

How to Select the Right Centrifugal Pump for Your Industrial Applications

-

Top 10 Diesel Transfer Tanks with Pumps for Efficient Fuel Management