How to Choose the Right Suction Pump for Your Industrial Needs

Choosing the right suction pump for your industrial needs can be a daunting task, given the wide variety of options available in the market today. A suction pump is crucial for effectively managing fluids in various industrial applications, from manufacturing to construction. Selecting the appropriate model ensures optimal performance, efficiency, and longevity, ultimately impacting your operational productivity and cost-effectiveness. In this guide, we will explore essential tips and numerical considerations that can help streamline your decision-making process. Whether you're dealing with water, chemicals, or viscous materials, understanding key factors such as capacity, material compatibility, and maintenance requirements will equip you with the knowledge to make an informed choice. Join us as we delve into the critical elements that define the best suction pump for your specific requirements.

Key Factors to Consider When Selecting a Suction Pump for Industrial Applications

When selecting a suction pump for industrial applications, there are several key factors to consider. Understanding the specific requirements of your operation is crucial. For instance, the type of materials being pumped—liquids, slurries, or gases—will greatly influence your choice. According to a recent industry report, over 60% of pump-related issues arise from the incorrect selection based on material compatibility and viscosity. Always ensure that the pump materials can withstand the chemical properties of the fluids involved.

Another important consideration is the required flow rate and pressure. Pumps are designed to operate efficiently within specific ranges, so having precise metrics for your needs is essential. Data from the Hydraulic Institute indicates that choosing a pump with a flow rate higher than necessary can lead to operational inefficiencies and increased costs. It’s vital to match the pump specifications to your operational requirements to ensure reliability and efficiency.

**Tip:** Always consult with pump manufacturers to understand the latest technological advancements, such as variable frequency drives (VFDs), which can optimize your pump's performance based on real-time demands.

**Tip:** Regular maintenance and monitoring of your suction pump can extend its lifespan. Implementing a predictive maintenance program can reduce downtime by up to 25%, giving you added efficiency in your industrial processes.

How to Choose the Right Suction Pump for Your Industrial Needs

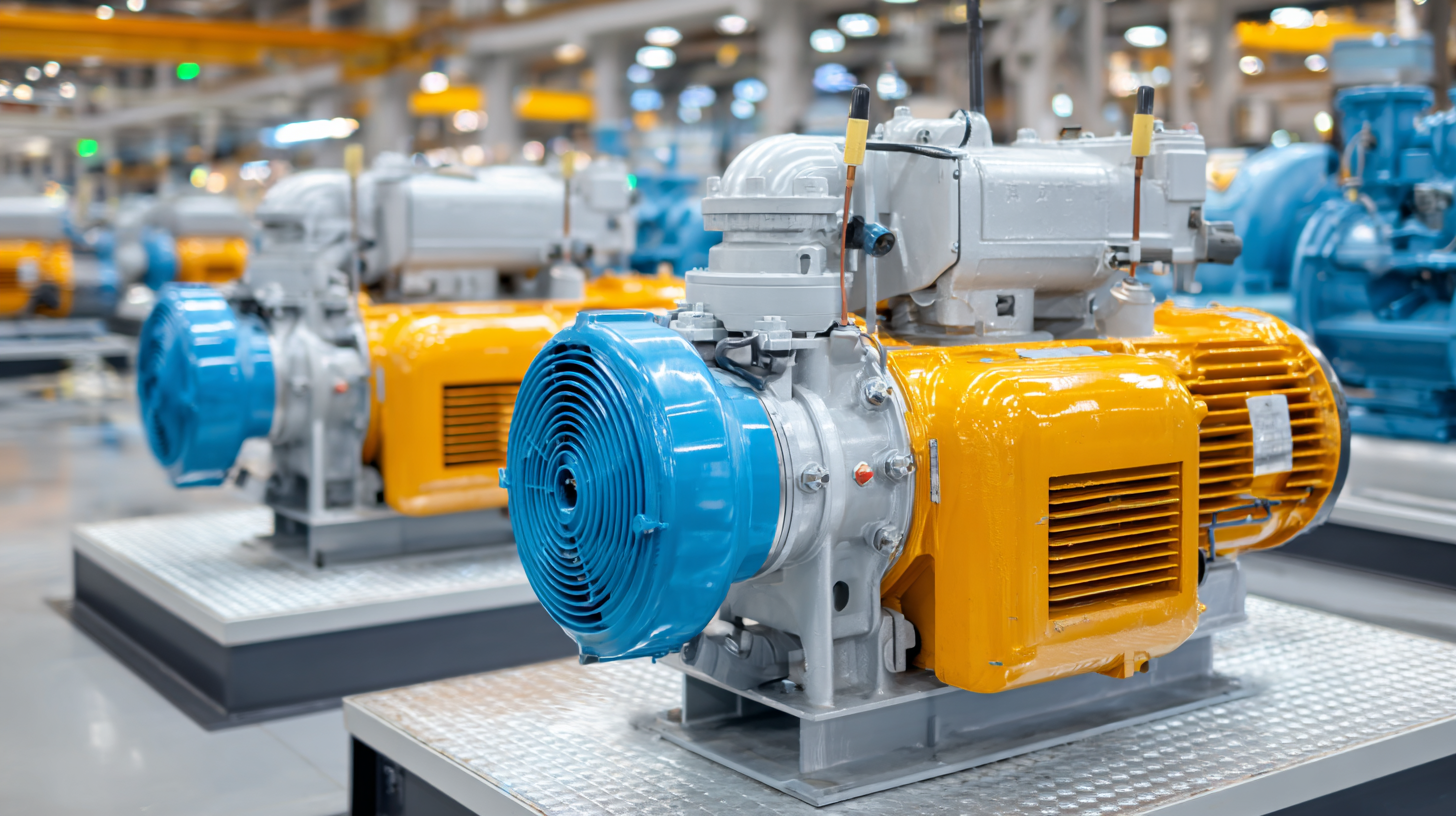

This chart presents key factors to consider when selecting a suction pump for industrial applications, such as flow rate, suction lift, and power consumption. Each factor is assessed to guide users in making informed decisions based on their specific needs.

Understanding Different Types of Suction Pumps and Their Uses in Industry

When selecting the right suction pump for industrial applications, it's crucial to understand the various types and their specific uses. Suction pumps can be primarily categorized into two types: positive displacement pumps and centrifugal pumps. Positive displacement pumps are ideal for applications requiring high viscosity fluids or where precise flow control is essential. These pumps function by trapping a fixed amount of fluid and forcing it through the discharge outlet, making them suitable for processes in the chemical and healthcare industries.

On the other hand, centrifugal pumps are commonly used in applications where large volumes of fluid need to be moved quickly. They operate by converting rotational kinetic energy into hydrodynamic energy, making them efficient for tasks in manufacturing and water treatment. Understanding the demands of your specific operation, including the type of fluid being handled, the required flow rate, and the system pressure, is vital in ensuring the selection of a suction pump that meets your industrial needs effectively. With the growing market for various types of pumps, such as those used in automotive and HVAC systems, addressing these factors can significantly enhance operational efficiency and reliability.

Evaluating Efficiency: How Pump Performance Metrics Influence Your Choice

When selecting a suction pump for industrial applications, evaluating efficiency is paramount. The performance metrics of a pump can significantly influence its operational effectiveness and, ultimately, your overall productivity. Key metrics such as flow rate, suction lift, and power consumption should be meticulously analyzed. Flow rate indicates the volume of fluid a pump can move within a specific time frame, which is crucial for meeting production demands. Suction lift refers to the maximum height the pump can draw liquid from; understanding this metric helps prevent operational failures.

In addition to these factors, it’s important to consider the pump's efficiency, which can be determined through its performance curve. This curve illustrates the relationship between flow rate and head, providing insights into how the pump performs under various conditions. A pump that operates closest to its best efficiency point can help minimize energy costs and reduce wear over time. Moreover, understanding the specific application—be it moving viscous fluids or handling abrasive materials—will inform your choice. By thoroughly evaluating these performance metrics, you can select a suction pump that not only meets your industrial requirements but also enhances your operational efficiency.

Industry Standards and Regulations Impacting Suction Pump Selection

When selecting a suction pump for industrial applications, it is crucial to consider the various industry standards and regulations that govern equipment performance and safety. Organizations such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) set specific criteria that manufacturers must adhere to, ensuring reliability and compatibility across different sectors. For instance, ANSI/HI standard 1.1 outlines centrifugal pump performance, specifying minimum efficiency levels that significantly impact operational costs and environmental sustainability.

Compliance with regulations not only ensures safety but also enhances efficiency. The Occupational Safety and Health Administration (OSHA) provides guidelines that address the safe use and maintenance of suction pumps, emphasizing the importance of selecting equipment that minimizes hazards to workers. In sectors like chemical processing, adherence to the Environmental Protection Agency (EPA) standards regarding emissions and waste management is essential. A well-chosen suction pump that meets or exceeds these regulations can save companies significant costs in fines and remediation while contributing to a more sustainable operational approach. Industry reports indicate that companies prioritizing regulatory compliance see a 30% reduction in operational risks, highlighting the importance of informed decision-making in pump selection.

Cost-Effectiveness: Analyzing the Total Cost of Ownership for Suction Pumps

When selecting a suction pump for industrial applications, it's essential to consider not just the initial purchase price but also the total cost of ownership (TCO). The TCO includes various factors such as energy consumption, maintenance expenses, and the lifespan of the pump. An energy-efficient model may come with a higher upfront cost, but the savings on electricity bills over time can significantly offset this initial investment. Companies should analyze their operational requirements and energy rates to determine which pump will provide the best long-term value.

Another critical component of TCO is maintenance. Regular service can prevent unexpected breakdowns and prolong the life of the pump. Choosing a model with accessible parts and reliable customer support can reduce downtime and minimize repair costs. Additionally, some pumps offer advanced monitoring technologies that can predict failures before they happen, further enhancing cost-effectiveness. By evaluating these aspects alongside the initial purchase price, industries can make informed decisions that align with their budgetary constraints and operational efficiency.

Related Posts

-

Ultimate Guide to Selecting the Right Fuel Transfer Tank with Pump: Expert Insights and Industry Standards

-

How to Choose the Right Fuel Transfer Tank with Pump for Your Needs

-

Progressive Cavity Pumps Exposed: A Comprehensive Comparison of Efficiency and Cost-Effectiveness

-

Ultimate Guide to Sourcing High Quality Diesel Tanks for Your Business Needs

-

Unlocking Efficiency and Cost Savings with Advanced Fuel Transfer Pump Solutions

-

How to Choose the Right Double Diaphragm Pump for Your Application