Top 10 Tips for Choosing the Right Metering Pump for Your Needs

Choosing the right metering pump can significantly impact your operations. According to industry expert Dr. Emily Carter, "Selecting a metering pump is crucial for precise chemical dosing." This insight highlights the importance of making an informed choice.

Metering pumps serve diverse needs across various sectors. They deliver precise liquid flows, ensuring consistent performance. However, many users overlook critical factors during selection. The right specifications, compatibility, and maintenance requirements often become an afterthought. Understanding these elements can lead to better efficiency and reliability.

In a market filled with options, determining which metering pump is best for your application can feel overwhelming. Users may face confusion when balancing price against performance. This can lead to regrettable choices. By reflecting on your specific needs and gathering relevant information, you can avoid these pitfalls, ensuring a long-lasting and effective solution.

Understanding the Different Types of Metering Pumps Available

When selecting a metering pump, it's essential to understand the various types available. Metering pumps come in different designs, such as diaphragm, peristaltic, and gear pumps. Each type serves specific applications and has unique advantages. Diaphragm pumps are known for their accuracy and reliability. They are widely used in wastewater treatment, chemical processing, and food industries. According to a recent industry report, diaphragm pumps account for about 35% of the global metering pump market due to their efficient performance.

Peristaltic pumps, on the other hand, excel in applications requiring gentle handling of fluids. They are ideal for transferring shear-sensitive liquids. These pumps operate by compressing a flexible tube, minimizing contamination risks. A survey indicated that approximately 25% of users in the pharmaceutical sector prefer peristaltic pumps for their ease of cleaning and maintenance. However, they may not be suitable for high-pressure applications, which is a significant drawback.

Gear pumps are another popular option. They provide a steady flow and are often used in oil and lubrication systems. However, they may experience flow fluctuations if not sized correctly. In some cases, users reported challenges in adapting gear pumps for varying viscosities. These factors highlight the importance of understanding each pump's capabilities and limitations. Choosing the right metering pump requires careful consideration of specific needs and potential pitfalls.

Identifying Your Specific Application Requirements for Metering Pumps

Choosing the right metering pump begins with understanding specific application requirements. Start with flow rate demands. Industry reports indicate that applications often require rates from as low as 0.1 mL/min to 1000 L/h. Knowing your precise flow requirement is crucial.

Next, consider the fluid properties. Is it viscous or corrosive? Fluids can vary significantly. Reports show that over 30% of pump failures stem from inadequate consideration of fluid characteristics. This can result in increased downtime.

The installation environment also plays a critical role. Is the pump exposed to extreme temperatures? Do vibrations affect performance? An estimated 15% of users overlook these factors. Reflecting on past choices may help avoid similar issues in the future. Balancing all these aspects is key to ensuring that your selected metering pump meets operational needs effectively.

Evaluating Flow Rate and Pressure Specifications for Optimal Performance

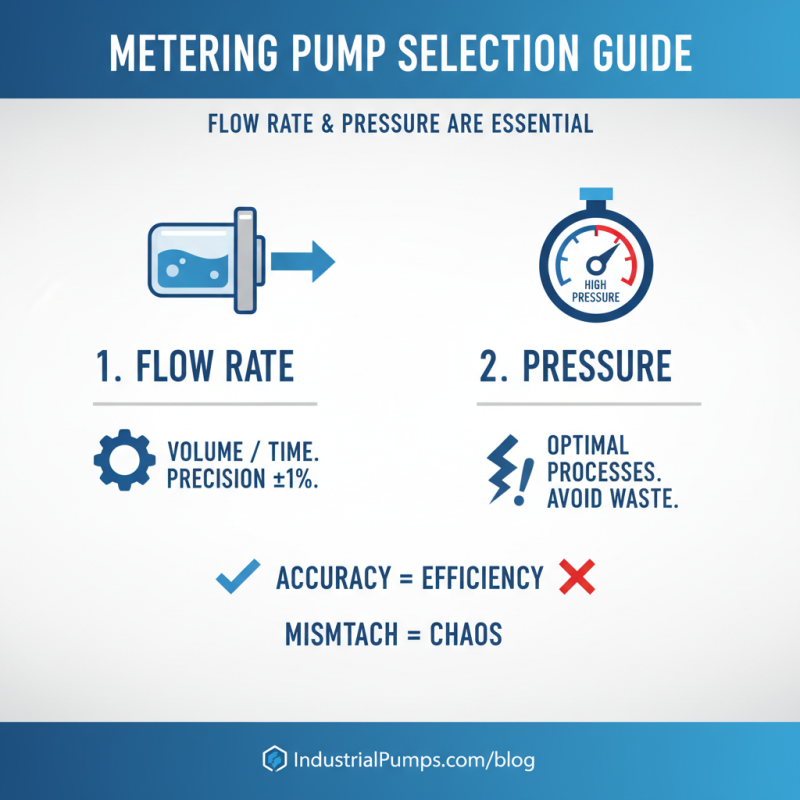

When selecting a metering pump, evaluating flow rate and pressure is essential. Flow rate is the volume of liquid delivered per unit time. Industry standards often require a flow rate precision within ±1%. Accurate flow measurement ensures that your processes run smoothly and efficiently. A mismatch can lead to operational chaos and material waste.

Pressure specifications can't be overlooked. Most metering applications operate between 5 to 150 psi. Understanding your requirements aids in choosing a pump that meets system demands. Insufficient pressure can result in backflow or leaks, while excessive pressure might damage equipment. A report from the American Society of Mechanical Engineers notes that improper pressure adjustments can cause a 20% increase in energy consumption.

It’s easy to overlook details during the selection process. Many users focus on just one metric. Such oversights can lead to unexpected costs. Regularly reviewing your pump's performance can also identify issues before they escalate. Keep in mind that what works today may not be suitable tomorrow. Continuous evaluation is key to optimal pumping performance.

Assessing Material Compatibility for Chemical and Fluid Handling

Choosing the right metering pump is essential for effective chemical and fluid handling. Material compatibility plays a significant role in this decision. When selecting a pump, consider the type of fluid it will handle. Different materials react uniquely to various chemicals. A mismatch can lead to costly damage or unsafe conditions.

One important tip is to evaluate the pump materials. Some materials like stainless steel, PVC, and polyethylene have different resistance levels. Conduct thorough research to understand the chemical compositions. Ask yourself if the fluid will corrode the pump over time. This could be a hidden cost in your project.

Another factor to consider is temperature and pressure ratings. High temperatures may cause some materials to degrade quickly. Likewise, varying pressure levels can impact the pump’s performance. Testing under actual conditions can provide clarity. Measure resistance and see if it aligns with your expectations. Reflect on potential failures, and choose wisely.

Top 10 Tips for Choosing the Right Metering Pump for Your Needs

This chart illustrates the importance levels of various factors to consider when selecting a metering pump. Each aspect, from chemical resistance to power requirements, contributes to the overall efficiency and compatibility for specific applications.

Consideration of Maintenance Needs and Ease of Operation

Choosing the right metering pump requires careful attention to maintenance needs. Look for pumps designed for easy upkeep. Simple designs often lead to fewer problems. For instance, pumps with external lubrication points make maintenance more straightforward. This can save time and reduce downtime.

Consider how often you will operate the pump. Frequent use might demand more rigorous maintenance routines. Ensure you find a pump that allows for easy access to components. Some systems make it hard to reach critical areas. This can be frustrating when you need to perform inspections or replace parts.

Think about the training required for operation. An intuitive design will reduce the training time. However, intricate systems may confuse operators. Balancing features with usability is critical. A pump may have advanced capabilities, but if it’s too complex, it may lead to mistakes. Reflect on the actual operation and long-term requirements. It's easy to overlook this until issues arise.

Top 10 Tips for Choosing the Right Metering Pump for Your Needs

| Tip | Consideration | Maintenance Needs | Ease of Operation |

|---|---|---|---|

| 1. Assess Your Fluid Type | Compatibility with fluid properties. | May require specific materials for durability. | Simple if fluid type is standard. |

| 2. Determine Required Flow Rate | Flow needs based on application. | Regular checks for efficiency. | User-friendly if flow is constant. |

| 3. Check Pressure Requirements | System pressure affects pump choice. | High-pressure systems require specific checks. | Moderate complexity, varies by pump. |

| 4. Evaluate Power Source | Electric, pneumatic, or hydraulic options. | Different sources require different maintenance. | Ease varies with technical knowledge. |

| 5. Consider Installation Space | Size and layout of installation area. | Should allow access for maintenance. | Compact designs facilitate easy operation. |

| 6. Look for Additional Features | Automation and monitoring benefits. | Can reduce manual checks and servicing. | Enhances user experience and simplifies tasks. |

| 7. Review Manufacturer Support | Check warranty and customer service. | Reliable support eases maintenance concerns. | Quick resolution of operation issues. |

| 8. Conduct Cost Analysis | Initial and ongoing costs comparison. | Lower costs may mean higher maintenance needs. | Operational costs should fit budget. |

| 9. Prioritize Safety Features | Safety measures for the specific environment. | Maintenance impacts safety functionality. | Ease of use contributes to safe operation. |

| 10. Read Reviews and Testimonials | Experiences from other users. | Good feedback on maintenance can guide choice. | User-friendly pumps often highlighted. |

Related Posts

-

Top Strategies for Enhancing Efficiency with Metering Pumps

-

5 Best Diesel Fuel Tank Solutions for Your Business Efficiency

-

Why Understanding Diesel Tanks is Essential for Your Business Operations

-

How to Choose the Right Chemical Dosing Pump for Your Industrial Needs

-

How to Choose the Right Vacuum Pump for Your Needs: A Complete Guide

-

Top 5 Diesel Transfer Tanks with Pump for Efficient Fuel Management