How to Choose the Right Gear Pump for Your Application Needs

When it comes to fluid transfer in various industrial applications, selecting the appropriate gear pump is crucial to ensure operational efficiency and reliability. Gear pumps, characterized by their positive displacement mechanism, play a vital role in handling a wide range of fluids, from viscous substances to light oils. Understanding the fundamental principles that govern gear pump performance can significantly influence the success of your application, whether it involves hydraulic systems, lubrication, or transferring chemicals.

The process of choosing the right gear pump involves several considerations, including flow rate, pressure requirements, fluid characteristics, and installation environments. Each of these factors can impact pump performance and longevity, necessitating a thorough evaluation before making a selection. Additionally, understanding the various types of gear pumps available in the market, such as internal and external gear pumps, can help in matching the specific needs of your application. By taking the time to analyze these criteria, users can make informed decisions that enhance system efficiency and reduce maintenance issues in the long run.

Understanding the Basics of Gear Pumps and Their Functionality

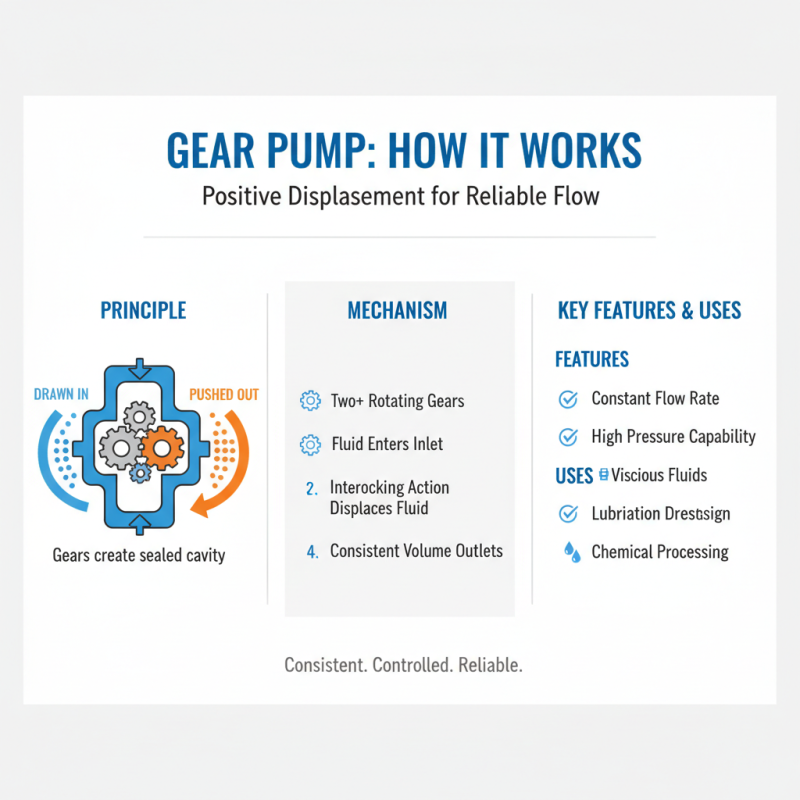

Gear pumps are a type of positive displacement pump that function by using the mechanical action of gears to move fluids. At their core, these pumps consist of two or more gears that rotate within a casing, creating a sealed cavity that draws fluid in and pushes it out. As the gears turn, the interlocking design ensures that the volume of fluid being displaced is consistent and controlled, making gear pumps ideal for various applications requiring reliable flow rates.

The functionality of gear pumps can be divided into two main types: external and internal. External gear pumps use two gears that mesh together outside of the fluid chamber, while internal gear pumps have one gear within another. Both designs effectively create suction to draw fluid in, but they may be better suited for different types of applications based on factors such as viscosity, pressure requirements, and flow rates. Understanding these fundamentals of gear pump operation is critical when selecting a pump that meets the demands of your specific application, whether it's for lubrication, hydraulic systems, or other industrial uses.

Identifying Your Specific Application Requirements for Gear Pumps

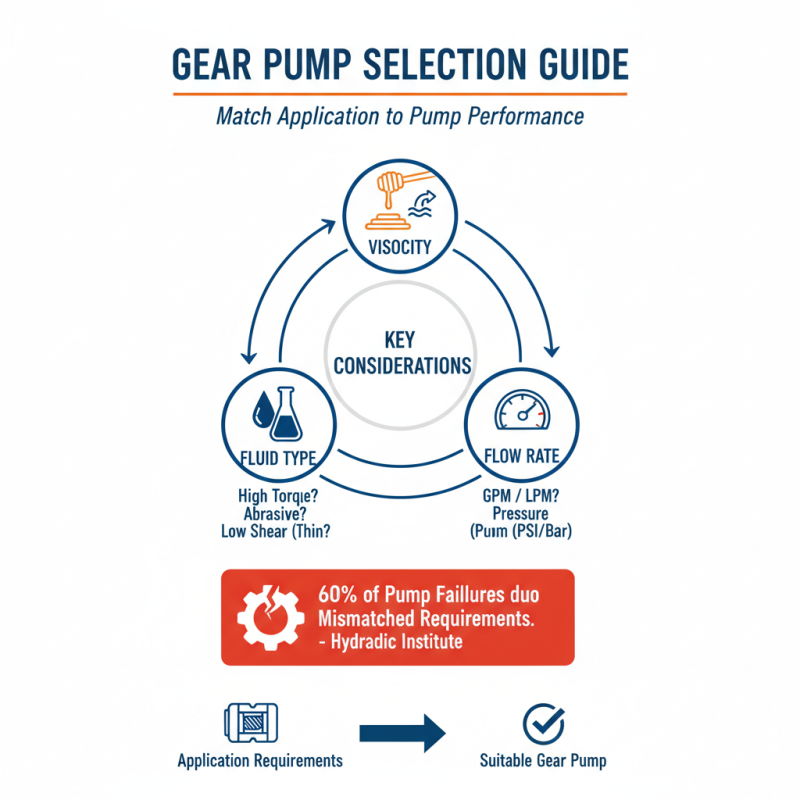

When selecting a gear pump, it is critical to first identify the specific application requirements that will dictate the performance and efficiency of the pump. According to a report by the Hydraulic Institute, over 60% of pump failures are attributed to mismatched application requirements, underscoring the importance of thorough assessment. Factors such as the type of fluid being pumped, the fluid viscosity, and the desired flow rate are paramount in determining the suitable gear pump. For instance, applications involving highly viscous fluids may necessitate a pump designed for higher torque, whereas low-viscosity fluids may require a different design approach.

Additionally, operational conditions should be carefully considered, including the required pressure range and temperature fluctuations. A study conducted by the Pump Systems Matter initiative revealed that improper pump selection can lead to energy losses exceeding 30%. This highlights the necessity for precise calculations related to volumetric and mechanical efficiency. Applications in industries such as chemical processing, food and beverage, or hydraulic systems each have unique requirements that can influence the choice of gear pump. By understanding these specific needs, users can optimize both pump performance and longevity, ultimately leading to cost savings and enhanced operational reliability.

Evaluating the Key Factors in Gear Pump Selection

When selecting a gear pump for your application, several key factors must be evaluated to ensure optimal performance and efficiency. First and foremost, consider the fluid properties, including viscosity, temperature, and chemical compatibility. High-viscosity fluids may require a pump with specific gearing designs to maintain flow consistency, while temperature fluctuations can affect the material selection of the pump components. Understanding these fluid characteristics will help in identifying the appropriate gear pump configuration needed for successful operation.

Another critical element to assess is the required flow rate and pressure for your application. Gear pumps are known for their ability to generate high pressures while maintaining a steady flow rate, but each application has unique demands. Ensure that the selected pump can meet these specifications without compromising performance over time. Additionally, it is crucial to account for any potential fluctuations in demand or changes in operational conditions that may necessitate adjustments in pump capacity. By taking these factors into consideration, you can make an informed decision that aligns with your application needs.

Gear Pump Selection Factors

The chart above illustrates the key factors to evaluate when selecting a gear pump for your application needs. The importance levels are rated from 1 to 10, where higher values indicate greater importance. Factors include flow rate, viscosity, pressure, temperature, and material compatibility.

Comparing Different Types of Gear Pumps Available in the Market

When selecting a gear pump for specific application needs, it's essential to understand the different types available in the market. The most common types include spur gear pumps, helical gear pumps, and more complex designs like internal gear pumps. Spur gear pumps are popular for their simple design and effectiveness in transferring a wide range of fluids. They tend to operate with low pulsation and offer high efficiency, making them suitable for applications that require steady flow rates.

Helical gear pumps, on the other hand, are engineered for more demanding operations, capable of handling higher viscosity fluids. Their design minimizes shear on fluids, which is essential when dealing with sensitive materials. Additionally, internal gear pumps are another option worth considering, especially when a gentle pumping action is required. These pumps can handle abrasive and non-lubricating fluids effectively and are often used in chemical processing.

When comparing these types, attention should be paid to factors like flow rate, viscosity of the fluid, system pressure, and the nature of the fluid being pumped. Evaluating the operational conditions and fluid characteristics helps in making an informed decision, ensuring the selected pump will perform efficiently and effectively in the intended application. Understanding these distinctions allows users to choose the most suitable gear pump tailored to their specific requirements.

How to Choose the Right Gear Pump for Your Application Needs

| Pump Type | Ideal Viscosity Range | Flow Rate range | Typical Applications | Advantages | Disadvantages |

|---|---|---|---|---|---|

| External Gear Pump | Low to Medium Viscosity (1-1000 cP) | 0.5 - 500 GPM | Hydraulic systems, Fuel transfer | Simple design, Good efficiency | Limited self-priming capability |

| Internal Gear Pump | Medium to High Viscosity (500-100,000 cP) | 0.1 - 200 GPM | Chemicals, Oil & Lubricants | Handles high viscosity fluids, Compact design | More complex than external gear pumps |

| Gear Strip Pump | Low to Medium Viscosity (1-3000 cP) | 0.1 - 50 GPM | Food processing, Pharmaceuticals | Gentle pumping action, Easy maintenance | Limited flow rates, Higher cost |

| Helical Gear Pump | Low to Medium Viscosity (1-5000 cP) | 1 - 150 GPM | Viscous fluids, Adhesives | High efficiency, Smooth flow | Complex design, Higher manufacturing cost |

Maintenance and Troubleshooting Tips for Gear Pump Performance

Regular maintenance is essential for ensuring optimal performance of gear pumps. To begin with, routine inspection should focus on checking fluid levels and ensuring that the fluid is clean and free of contaminants. Contaminated fluids can cause wear and lead to premature failure of the pump components. Additionally, monitoring the pump's temperature is crucial; abnormal temperature increases may indicate excessive friction, leading to potential damage. Implementing a scheduled maintenance plan is instrumental in prolonging the life cycle of the gear pump.

When addressing troubleshooting, it's important to understand common issues that may arise during operation. For instance, irregular noises during pumping could signal issues such as cavitation or improper alignment. If a drop in pressure is observed, this might indicate wear in the gears or seals which could compromise the pump's integrity. To resolve these issues effectively, operators should consult the pump's manual, conduct a thorough examination, and replace any worn-out parts. Keeping a detailed log of maintenance and performance trends can also aid in predicting potential failures before they occur.

Related Posts

-

10 Essential Tips for Choosing the Right Gear Pump for Your Applications

-

How to Choose the Right Gas Pump for Your Business Needs

-

Unlocking Efficiency and Cost Savings with Advanced Fuel Transfer Pump Solutions

-

How to Choose the Right Centrifugal Pump for Your Industrial Needs

-

Unlocking Efficiency: The Advantages of Advanced Fuel Storage Tanks for Your Business

-

How to Choose the Right Chemical Dosing Pump for Your Industrial Needs