How to Choose the Right Gasoline Transfer Pump for Your Needs

Choosing the right gasoline transfer pump is crucial for ensuring efficiency and safety in various applications, ranging from automotive garages to agricultural operations. According to a report by the National Association of Oil and Energy (NAOE), the demand for gasoline transfer pumps has seen a consistent increase of approximately 5% annually, driven by the growing need for fuel management solutions in both commercial and residential sectors. The right pump not only enhances productivity but also minimizes the risk of spills and environmental hazards, emphasizing the importance of selecting a pump that meets specific needs and standards.

In addition, a recent study by the American Petroleum Institute (API) highlights that improper pump selection can lead to operational inefficiencies and increased costs. The diversity in pump types, sizes, and functionalities makes it imperative for users to assess their unique requirements before making a purchase. Factors such as flow rate, portability, and compatibility with various fuel types should be carefully considered to ensure that the gasoline transfer pump operates effectively and complies with industry regulations. By understanding these dynamics, users can make informed decisions that not only meet their immediate needs but also align with best practices in handling fuel safely.

Understanding Your Fuel Transfer Requirements

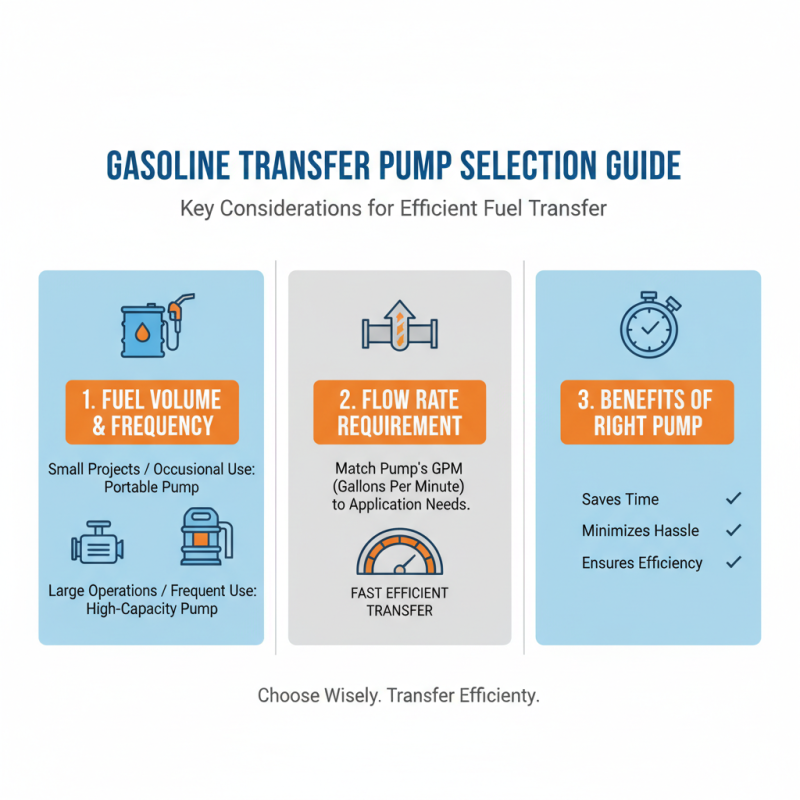

When selecting a gasoline transfer pump, it is essential to first assess your specific fuel transfer requirements. Consider the volume of fuel you will be handling, as well as the frequency of transfers. For occasional small projects, a portable pump may suffice, while larger operations often require a more robust, high-capacity pump designed for continuous use. Understanding the flow rate needed for your applications will ensure you choose a pump that can efficiently move fuel without delays, thereby saving time and minimizing hassle.

Furthermore, take into account the environment in which the pump will be used. Factors such as location accessibility, potential hazards, and temperature can influence your choice. If you plan to use the pump in rugged outdoor settings, a durable, weather-resistant model would be more suitable. Additionally, consider the ease of maintenance and whether the pump can be readily serviced or repaired as needed. By thoroughly evaluating these requirements, you can make an informed decision that aligns closely with your fueling needs.

Types of Gasoline Transfer Pumps Available

When selecting a gasoline transfer pump, it is vital to understand the various types available in the market to cater to specific needs. Primarily, gasoline transfer pumps can be categorized into manual, electric, and air-operated models. Manual pumps are often cost-effective and portable, making them suitable for personal use or small-scale operations. Electric pumps offer greater efficiency and speed, ideal for larger tasks requiring a quick transfer of gasoline. Air-operated pumps provide robust performance for industrial applications, offering high flow rates and durability.

Tips for choosing the right pump include assessing the flow rate you require; for instance, a report by the Pump Manufacturer's Association (PMA) indicates that flow rates can significantly vary, with electric pumps capable of delivering between 20 to 100 gallons per minute. Additionally, consider the environment in which the pump will be used. For example, an electric pump may not be suitable for remote locations without power supply, hence a manual or air-operated option could be more advantageous.

Another critical factor is safety. According to the National Fire Protection Association (NFPA), proper grounding and fuel transfer systems can significantly reduce the risk of fires or explosions. Therefore, ensure that any pump chosen adheres to local regulations and safety standards for the handling of gasoline.

Key Features to Consider When Choosing a Pump

When selecting the right gasoline transfer pump, there are several key features to consider to ensure it meets your specific requirements. One of the primary factors is the pump's flow rate, which typically ranges from 5 to 50 gallons per minute (GPM). According to the National Association of Fuel Oil Dealers (NAFDD), an optimal flow rate not only affects efficiency but can also impact refueling times, especially for commercial operations where downtime translates to lost productivity. Therefore, understanding the flow rate needed for your applications is crucial.

Another critical aspect to consider is the pump's power source. Gasoline transfer pumps can operate on electricity, battery, or gas. Electric pumps are generally quieter and more efficient for indoor use, but can be limited by outlet accessibility. Conversely, gas-powered models, while more powerful and portable, may produce more noise and emissions. Additionally, users should pay attention to the durability of materials used in the pump’s construction. According to a report by the American Institute of Chemical Engineers (AIChE), high-quality materials like aluminum or stainless steel can greatly enhance a pump's longevity, particularly when dealing with corrosive substances or harsh operational conditions. Taking these features into account will enable you to choose a pump that not only fits your immediate needs but also provides reliable performance for years to come.

How to Choose the Right Gasoline Transfer Pump for Your Needs - Key Features to Consider When Choosing a Pump

| Feature | Description | Importance |

|---|---|---|

| Flow Rate | The speed at which the pump transfers gasoline, typically measured in gallons per minute (GPM). | High flow rate is essential for efficiency, particularly for frequent users. |

| Power Source | The source of power for the pump, which could be electric or gasoline-powered. | Choosing the right power source can impact portability and operational costs. |

| Portability | How easy it is to move and store the pump. | Important for users needing to transport the pump for various applications. |

| Durability | The ability of the pump to withstand harsh conditions and prolonged use. | Critical for longevity and reliability in demanding environments. |

| Safety Features | Incorporated features that prevent spills, overflows, and other hazards. | Essential for safe operations, especially in commercial applications. |

| Noise Level | The sound produced by the pump during operation. | Lower noise levels are preferable for residential and close-quarter operations. |

| Warranty | Length and coverage of the warranty provided by the manufacturer. | A longer warranty can indicate better product reliability and manufacturer support. |

Assessing Pump Capacity and Flow Rate Needs

When selecting a gasoline transfer pump, assessing the pump's capacity and flow rate is crucial to ensure it meets your specific needs. Typically, gasoline transfer pumps are available in various capacities, often ranging from 5 to 50 gallons per minute (GPM). For light usage, such as small vehicles or equipment, a pump with a capacity of around 5 to 15 GPM is often sufficient. However, for larger operations or situations where efficiency is vital, selecting a pump that offers higher flow rates can significantly reduce the transfer time, allowing for smooth and quick fueling.

Flow rate also influences the overall effectiveness of your gasoline transfer pump. According to the American Petroleum Institute, a pump's flow rate must not only accommodate the volume needed but should also match the delivery system’s design to avoid issues like cavitation or pressure drops. For example, in a medium-sized facility needing to refuel multiple vehicles, a pump with a capacity of 30 GPM would be more effective than a lower-capacity option, ultimately leading to enhanced productivity. The key is to analyze your typical fueling needs, prioritize efficiency, and consider potential future requirements, ensuring that the chosen pump is versatile enough to handle them.

Evaluating Safety and Compliance Standards for Pumps

When selecting a gasoline transfer pump, evaluating safety and compliance standards is crucial to ensure both operational efficiency and user protection. Compliance with industry standards, such as those set by the American National Standards Institute (ANSI) and Underwriters Laboratories (UL), can significantly mitigate risks associated with handling flammable liquids. According to a report by the National Fire Protection Association (NFPA), improper use of gasoline transfer pumps contributes to approximately 5,000 fire incidents each year, underlining the importance of choosing pumps that meet stringent safety guidelines.

Furthermore, the Environmental Protection Agency (EPA) emphasizes the necessity for pumps to have proper spill containment measures and fail-safes to prevent leaks. A study conducted in 2020 found that nearly 60% of incidents involving gasoline transfer are linked to equipment failure or lack of compliance with safety protocols. Therefore, selecting a pump designed with compliance features such as automatic shut-off valves, vapor recovery systems, and durable materials resistant to corrosion is essential not only for user safety but also for environmental protection. As regulations become increasingly stringent, it is imperative for users to prioritize these safety measures to prevent potential hazards and comply with legal requirements.

Gasoline Transfer Pump Safety Compliance by Type

Related Posts

-

Everything You Need to Know About Transfer Tank Pumps: Your Ultimate Guide to Safe Fuel Handling

-

How to Choose the Best Diesel Transfer Tank with Pump for Your Needs in 2025

-

How to Choose the Right Gas Transfer Pump for Your Needs

-

How to Choose the Right Gas Pump for Your Business Needs

-

Exploring Vacuum Pump Innovations at the 138th Canton Fair 2025: Trends and Data Insights

-

How to Choose the Right Vacuum Pump for Your Needs: A Complete Guide