Top 10 Tips for Choosing the Right Diesel Tank with Pump for Your Needs

When it comes to selecting the right diesel tank with pump, it can often feel overwhelming due to the myriad of options available on the market. As industry expert John Smith, a renowned consultant in fuel storage solutions, aptly states, "Choosing the right diesel tank with pump is not just about capacity; it’s about ensuring safety, efficiency, and compliance with regulations." This insightful perspective underscores the importance of making an informed decision tailored to your specific requirements.

Understanding your needs is crucial, whether for commercial, agricultural, or personal use. Various factors come into play, such as tank size, pump capacity, material, and additional features that can enhance functionality and safety. With the right guidance, businesses and individuals alike can navigate the complexities of the tank selection process and invest in a solution that meets both current and future demands.

In this article, we will explore the top 10 tips for choosing the perfect diesel tank with pump for your needs. By highlighting essential considerations and expert recommendations, we aim to empower you with the knowledge necessary to make a confident purchase that aligns with your operational goals and regulatory obligations.

Understanding Your Diesel Storage Needs

When selecting the right diesel tank with a pump, understanding your diesel storage needs is crucial. The first step in this process is to assess the volume of diesel you require. This involves considering factors such as your fuel consumption rate, the frequency of refueling, and the specific applications for which the diesel will be used. Knowing whether you need to store a small quantity for personal use or a larger volume for commercial purposes will influence the size and type of tank you should choose.

In addition to volume, it's important to evaluate the space available for installation. Consider the dimensions of the location where the tank will be placed, ensuring that it complies with any applicable safety regulations and standards. Accessibility for both fueling and maintenance is also key. Finally, think about environmental considerations; select a tank that offers protection against leaks and spills to safeguard both your property and the surrounding ecosystem. By clearly identifying your diesel storage requirements, you can make a well-informed decision that meets both your operational needs and safety standards.

Evaluating Tank Size and Capacity Requirements

When evaluating tank size and capacity requirements for diesel tanks equipped with pumps, it's essential to assess your operational needs carefully.

According to the Diesel Technology Forum, the average diesel usage for commercial vehicles can vary significantly, with some fleets consuming between

5,000 to 15,000 gallons per month. Therefore, selecting the appropriate tank capacity is crucial to minimize refueling times and ensure efficiency in your operations.

Understanding your consumption patterns is key to determining the right tank size.

For example, if your operations require frequent refueling, a larger tank with a capacity of

1,000 gallons or more may be necessary to support your demands. Conversely, if your fuel consumption is lower, a smaller tank might suffice, helping to manage costs effectively.

The Environmental Protection Agency (EPA) recommends maintaining a fuel level that ensures

turnover and freshness while avoiding excess storage that can lead to contamination risks. Ultimately, aligning your tank size with your operational needs will not only enhance efficiency but also ensure compliance with industry regulations.

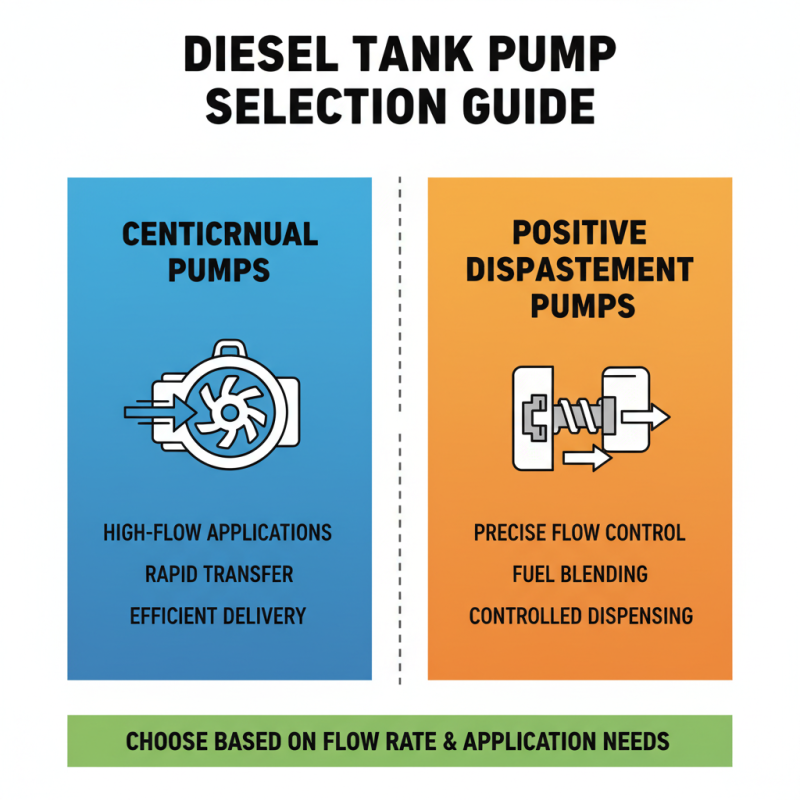

Selecting the Right Pump Type and Specifications

When selecting the right pump for your diesel tank, it’s crucial to consider the specific application and requirements you have. Different pump types are designed for various operational conditions and fluid viscosities. For instance, centrifugal pumps are commonly used for high-flow applications, delivering diesel quickly and efficiently. On the other hand, positive displacement pumps are ideal for applications needing precise flow control, making them suitable for blending fuels or delivering products in a controlled manner. Evaluate the flow rate required for your operations to ensure the pump meets your demands without compromising efficiency.

Another important aspect to consider is the pump specifications, such as power source, pressure rating, and material compatibility. Diesel pumps may be powered electrically or pneumatically, depending on your environment and preferences. Make sure to assess the pressure rating to ensure it aligns with the anticipated lift and discharge needs. Additionally, consider the compatibility of the pump materials with diesel fuel, as certain materials may degrade over time, leading to maintenance issues. Ensuring that your pump can handle the specific characteristics of diesel will prolong its lifespan and maintain optimal performance in the long run.

Considering Safety Features and Regulations

When choosing a diesel tank with a pump, safety features and regulatory compliance are of utmost importance. According to the Environmental Protection Agency (EPA), improper handling of diesel can lead to environmental hazards, underscoring the need for tanks that meet stringent safety standards. Look for tanks that are designed with secondary containment to prevent leaks and spills, as well as features like overfill alarms to avert potential disasters. Additionally, many regions require compliance with local regulations, which can include specific material requirements, labeling, and maintenance checks. Failing to adhere to these guidelines can lead to costly penalties and increased liability.

Tip: Always ensure that the diesel tank you choose has been tested and certified according to the relevant safety standards, such as those set by Underwriters Laboratories (UL) or the American Society for Testing and Materials (ASTM). These certifications provide peace of mind that your tank meets the necessary safety and performance benchmarks.

Moreover, pay attention to the design of the pump and its compatibility with the tank. A secure, efficient pump will enhance safety during operation and minimize risks associated with fuel transfer. Installation should be handled by professionals to ensure that it meets environmental safety regulations. It’s crucial to stay informed about both local regulations and industry guidelines, which evolve over time to address new safety standards and environmental concerns. Engaging with updated industry reports can provide valuable insights into best practices for fuel storage and safety compliance.

Assessing Installation and Maintenance Factors

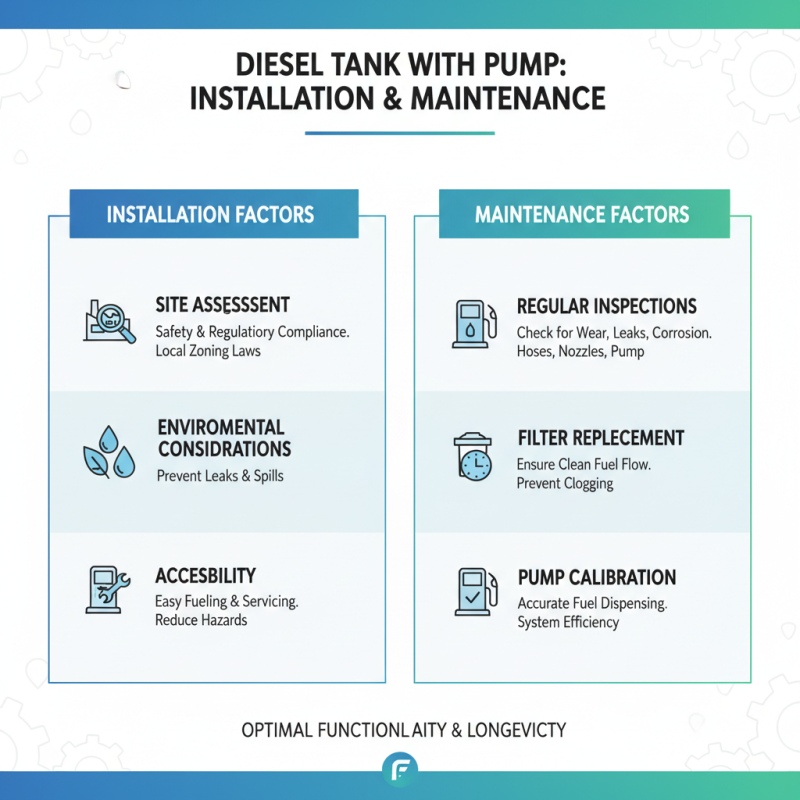

When selecting a diesel tank with a pump, installation and maintenance factors are crucial considerations that can significantly impact the tank's functionality and longevity. First, assess the installation site to ensure it meets all safety and regulatory requirements. Consider the surrounding environment, as well as any local zoning laws that may dictate the tank's placement. Proper installation not only helps prevent leaks and spills but also ensures efficient operation of the pump system. Installing the tank in a location that is easily accessible for fueling and maintenance can save time and reduce potential hazards.

Regular maintenance is essential for the optimal performance of your diesel tank and pump. Establish a routine inspection schedule to check for leaks, corrosion, and wear on hoses and fittings. It's advisable to clean the tank periodically to prevent sediment build-up, which can impair pump efficiency and contaminate the fuel. Additionally, ensure that all safety features, such as emergency shut-off systems and spill containment options, are functioning correctly. By prioritizing installation and maintenance, you can enhance the reliability and lifespan of your diesel tank system, ensuring that it effectively meets your operational needs.

Related Posts

-

Understanding the Benefits of a Diesel Transfer Tank with Pump for Efficient Fuel Management

-

Maximizing Efficiency and Safety with Diesel Transfer Tanks Featuring Pumps in the Fuel Industry

-

Top 10 Diesel Transfer Tanks with Pumps for Efficient Fuel Management

-

Top 5 Diesel Transfer Tanks with Pump for Efficient Fuel Management

-

How to Choose the Best Fuel Transfer Tank with Pump for Your Needs

-

Ultimate Guide to Sourcing High Quality Diesel Tanks for Your Business Needs