How to Choose the Right Centrifugal Pump for Your Industrial Needs

Choosing the right centrifugal pump for your industrial needs requires a careful assessment of various factors that can significantly impact performance and efficiency. Centrifugal pumps are widely used in various applications, from water treatment to chemical processing, making it crucial to understand the specific requirements of your operation.

Key considerations include flow rate, head, fluid properties, and system compatibility, all of which can influence the effectiveness of the pump. Additionally, understanding the different types of centrifugal pumps available and their operational principles can help you make an informed decision.

This guide aims to provide insights into the selection process, highlighting essential criteria to help you choose a centrifugal pump that meets your operational demands while optimizing efficiency and reliability.

Choosing the right centrifugal pump for your industrial needs requires a careful assessment of various factors that can significantly impact performance and efficiency. Centrifugal pumps are widely used in various applications, from water treatment to chemical processing, making it crucial to understand the specific requirements of your operation.

Key considerations include flow rate, head, fluid properties, and system compatibility, all of which can influence the effectiveness of the pump. Additionally, understanding the different types of centrifugal pumps available and their operational principles can help you make an informed decision.

This guide aims to provide insights into the selection process, highlighting essential criteria to help you choose a centrifugal pump that meets your operational demands while optimizing efficiency and reliability.

Understanding the Importance of Centrifugal Pumps in Industrial Applications

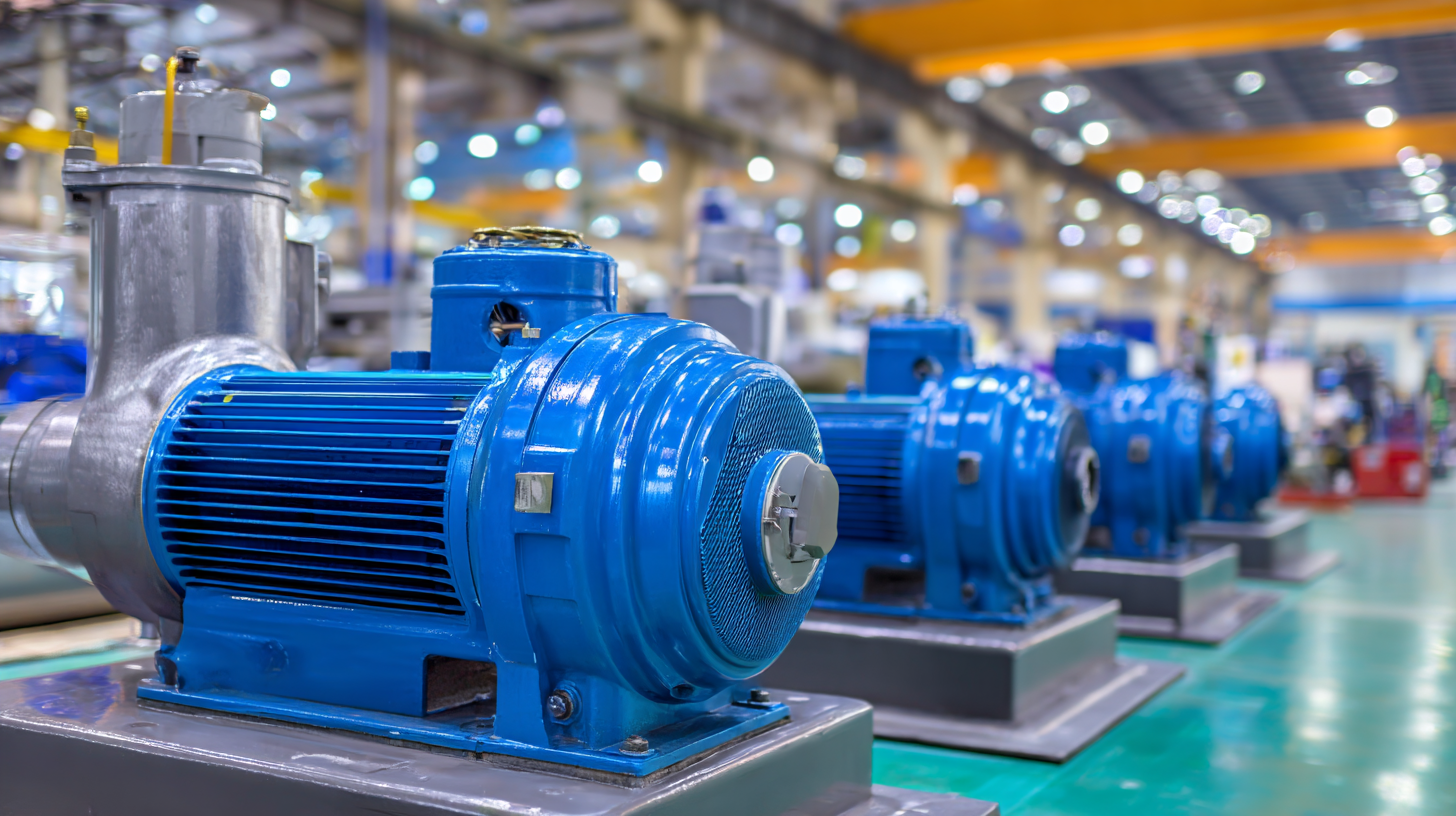

Centrifugal pumps play a crucial role in various industrial applications by facilitating the movement of fluids efficiently. These pumps utilize rotational energy from a rotor to impart velocity to the fluid, converting kinetic energy into pressure energy. This process makes them particularly effective for transporting large volumes of liquids at relatively low viscosities, which is essential in sectors such as chemical processing, water treatment, and oil and gas production.

Understanding the importance of centrifugal pumps goes beyond just recognizing their functionality. Selecting the right pump is critical for ensuring optimal performance and reliability in industrial operations. Factors such as the fluid characteristics, system pressure requirements, and required flow rates must be carefully evaluated to choose a pump that can withstand the demands of the specific application. Inadequate selection can lead to inefficiencies, increased operational costs, and potential equipment failures, underscoring the need for a comprehensive understanding of how these pumps operate within the broader industrial ecosystem.

Industrial Applications of Centrifugal Pumps

Key Factors Influencing Centrifugal Pump Performance and Selection Criteria

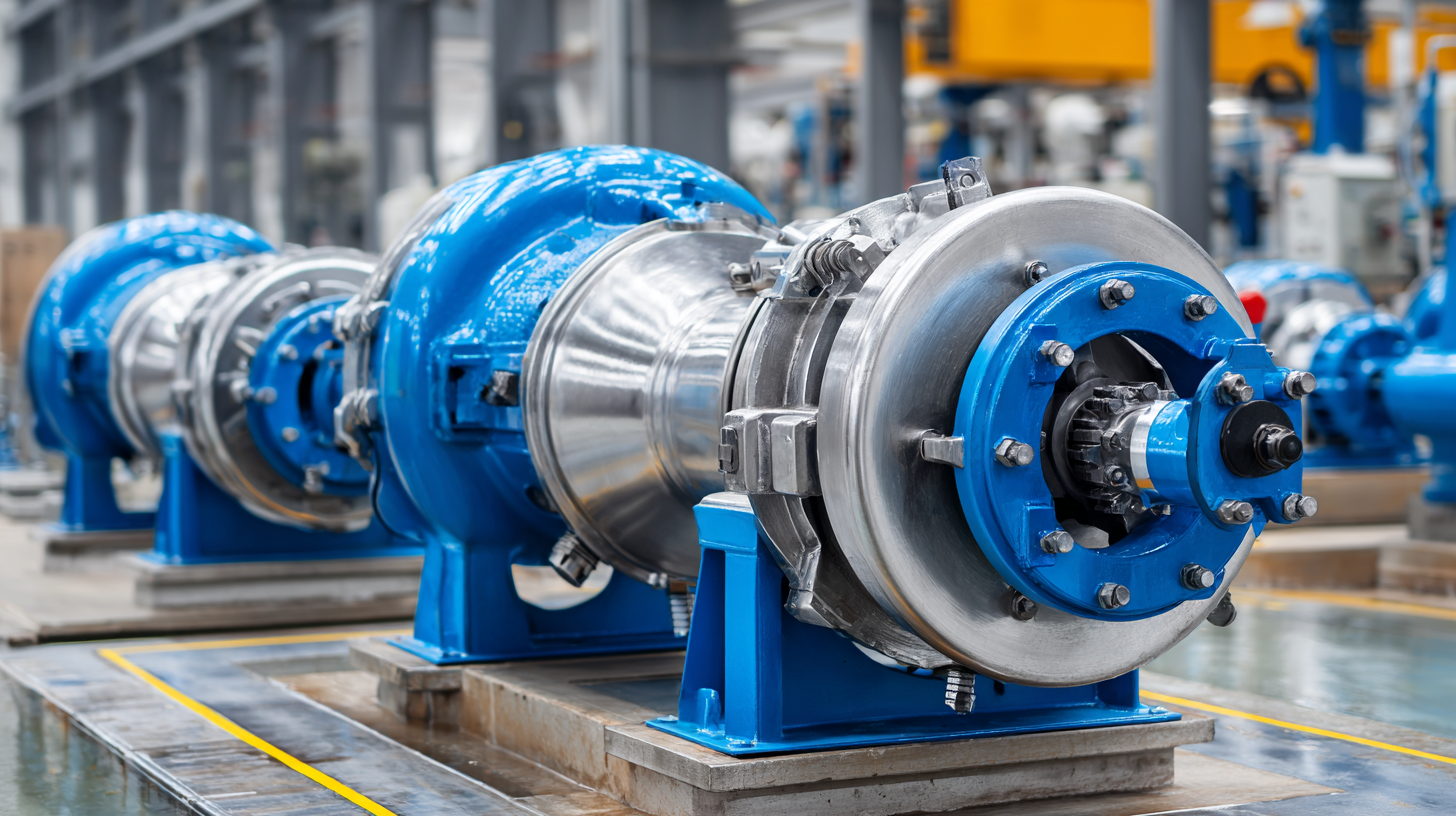

When selecting a centrifugal pump for industrial applications, several key factors influence performance and overall effectiveness. One of the foremost considerations is the fluid properties, including viscosity, temperature, and corrosiveness. Understanding these parameters ensures compatibility between the pump materials and the fluid, which minimizes wear and extends equipment life. Additionally, the specific gravity of the fluid affects the pump's efficiency and selection, as variations can lead to differences in horsepower requirements and potential cavitation issues.

Another critical factor is the system head requirement, which encompasses both the total dynamic head (TDH) and the friction losses within the piping system. Calculating these values helps in determining the correct pump size and type to ensure optimal flow rates and suction capability. Furthermore, operational parameters such as flow rate variations and the presence of solids in the fluid can dictate the need for specific pump designs, such as those with robust construction or adjustable performance features. By carefully analyzing these factors, industrial operators can select a centrifugal pump that meets their unique requirements and achieves reliable performance in demanding environments.

Evaluating Flow Rate and Head Requirements for Optimal Pump Operation

When selecting a centrifugal pump for industrial applications, understanding flow rate and head requirements is critical for optimal performance. Flow rate, measured in gallons per minute (GPM) or liters per second (L/s), indicates the volume of fluid a pump can handle. Industry standards suggest that the required flow rate should be calculated based on the specific process demands and the characteristics of the fluid being pumped. For instance, a report from the Hydraulic Institute states that for most industrial operations, maintaining a flow rate that is 10-20% above the minimum requirement is advisable to accommodate fluctuations and ensure efficiency.

Head, or the height to which a pump can raise a fluid, is another crucial factor. It is typically measured in feet or meters and considers the total static lift and the friction losses in the piping system. According to the American National Standards Institute (ANSI), an accurate assessment of total dynamic head (TDH) allows for better pump selection and helps avoid common issues such as cavitation or inefficient operation. A study highlighted that miscalculating head requirements can result in a 30% drop in pump efficiency, emphasizing the importance of precise evaluation to optimize operational performance and reduce energy costs.

How to Choose the Right Centrifugal Pump for Your Industrial Needs

| Pump Type | Flow Rate (GPM) | Head (Feet) | Application | Efficiency (%) |

|---|---|---|---|---|

| Single Stage | 50 | 100 | Water Transfer | 75 |

| Multistage | 100 | 250 | High Pressure | 85 |

| Submersible | 75 | 50 | Drainage | 70 |

| Self-Priming | 60 | 40 | Liquid Transfer | 80 |

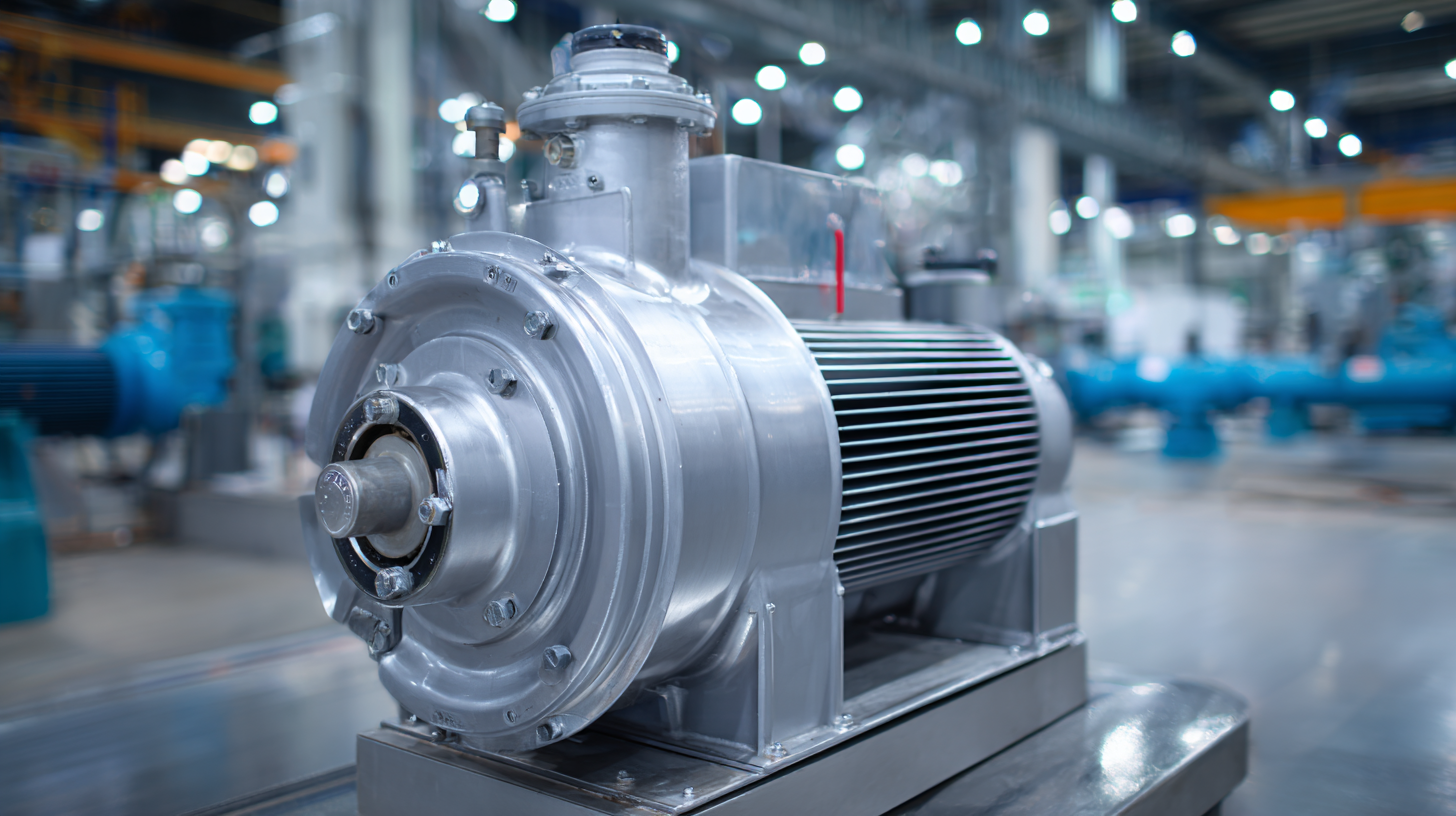

Assessing Material Compatibility and Pump Construction Materials for Durability

When selecting a centrifugal pump for industrial applications, assessing material compatibility and construction materials is crucial for ensuring durability and optimal performance.

Different fluids, whether corrosive, abrasive, or viscous, require pumps made from materials that can withstand their specific properties. For instance, if the pump will handle acidic substances, materials like stainless steel or specific plastics may offer the necessary resistance to corrosion. Understanding the chemical makeup and temperature of the fluids being pumped allows operators to select materials that will not degrade over time.

Different fluids, whether corrosive, abrasive, or viscous, require pumps made from materials that can withstand their specific properties. For instance, if the pump will handle acidic substances, materials like stainless steel or specific plastics may offer the necessary resistance to corrosion. Understanding the chemical makeup and temperature of the fluids being pumped allows operators to select materials that will not degrade over time.

In addition to chemical compatibility, the construction materials of the pump significantly impact its longevity and reliability. Pumps made with high-grade alloys or reinforced composites often have superior resistance to wear and fatigue, making them ideal for heavy-duty applications. It's also essential to consider the operating environment; high temperatures and pressure cycles can strain weaker materials. By prioritizing both material compatibility and robust construction, industries can enhance the lifespan of their pumping systems and reduce maintenance costs significantly.

Cost-Benefit Analysis: Short-Term vs Long-Term Investment in Pump Technologies

When considering the right centrifugal pump for your industrial needs, the cost-benefit analysis between short-term and long-term investments is crucial. Initially, a cheaper pump may seem appealing due to lower upfront costs. However, in the long run, these pumps might require more frequent maintenance and replacement, leading to higher overall operational costs. Investing in a higher-quality pump may result in significant savings over time due to reduced energy consumption, fewer repairs, and longer life expectancy.

Tips: When evaluating pumps, consider the total cost of ownership rather than just the initial purchase price. Look into the pump's efficiency ratings and warranty offers. Assess how the pump will fit into your existing system and operational processes to maximize productivity and minimize disruptions.

Ultimately, selecting the right pump involves balancing immediate budget concerns with the potential long-term savings and benefits. Analyzing your specific operational demands, maintenance capabilities, and anticipated usage will guide you in making a more informed decision that aligns with both your current and future industrial objectives.

Related Posts

-

How to Select the Right Centrifugal Pump for Your Industrial Applications

-

7 Reasons to Choose a Diesel Transfer Tank with Pump for Your Business

-

How to Choose the Right Air Operated Diaphragm Pump for Your Applications

-

How to Choose the Right Double Diaphragm Pump for Your Application

-

Progressive Cavity Pumps Exposed: A Comprehensive Comparison of Efficiency and Cost-Effectiveness

-

Ultimate Guide to Sourcing High Quality Diesel Tanks for Your Business Needs