How to Choose the Right Air Operated Diaphragm Pump for Your Applications

In the industrial sector, the selection of equipment plays a crucial role in maintaining efficiency and productivity. Among various pumping solutions, the air operated diaphragm pump has gained significant traction due to its versatility and reliability. According to a recent market research report by Grand View Research, the global diaphragm pump market is projected to reach USD 8.8 billion by 2025, driven by the increasing demand for safe and contained transfer of fluids across diverse applications. With their ability to handle a wide range of viscosities and chemical compatibilities, air operated diaphragm pumps are particularly favored in industries such as chemical processing, oil and gas, and food and beverage. Understanding the various types and specifications of these pumps is essential for selecting the right model that meets specific operational requirements, ensuring optimal performance and longevity in various applications.

Understanding the Basics of Air Operated Diaphragm Pumps

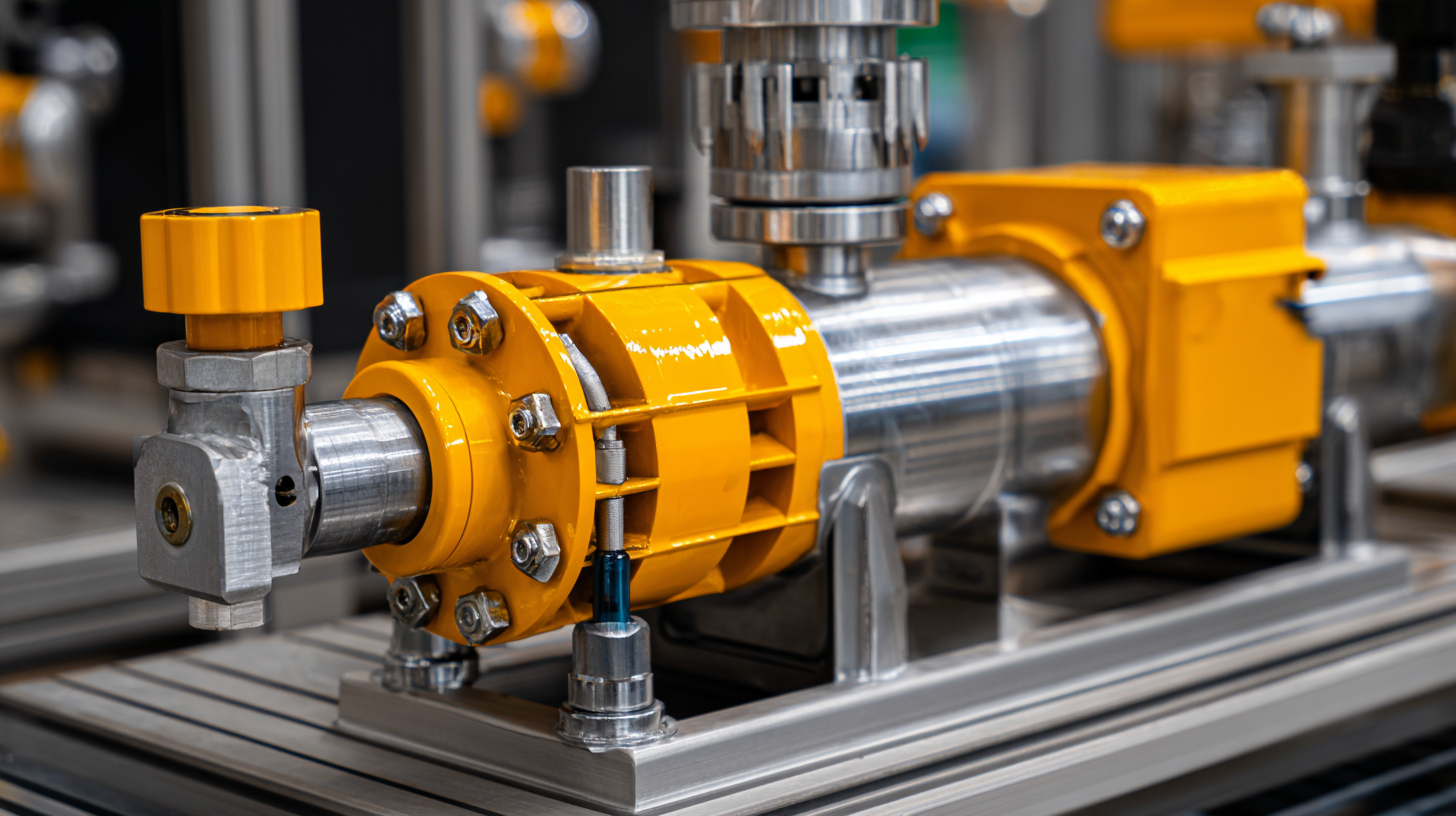

Air operated diaphragm pumps (AODDs) are versatile and efficient fluid handling solutions suitable for various applications. Understanding the basics of how these pumps operate is crucial for selecting the right model for your needs. At their core, AODDs utilize air pressure to move fluid through flexible diaphragms, allowing for a wide range of viscosities and fluid types. This unique mechanism of operation not only offers self-priming capabilities but also enables the transfer of abrasive and corrosive substances with ease.

One of the key advantages of AODDs is their simplicity and reliability. They can run dry without damage, making them ideal for intermittent service and applications where fluid supply may be inconsistent. Furthermore, the variety of materials used in diaphragm and pump construction means they can handle delicate liquids as well as harsh chemicals. When choosing an air operated diaphragm pump, it’s essential to consider the specific fluids you’ll be working with, the required flow rates, and any potential environmental factors that might affect performance. This foundational understanding can significantly enhance your decision-making process.

Key Factors to Consider When Selecting a Diaphragm Pump

When selecting an air operated diaphragm pump for specific applications, several key factors must be considered to ensure optimal performance. First, understanding the fluid characteristics is crucial. The viscosity, temperature, and chemical compatibility of the fluid can significantly impact the pump's efficiency and longevity. According to the Hydraulic Institute, over 30% of pump failures can be traced back to improper fluid selection. Therefore, always check the pump material compatibility charts provided by manufacturers.

Additionally, flow rate and pressure requirements should align with your application needs. Pumps are available in a variety of sizes and capacities, with some capable of handling flow rates up to 400 gallons per minute. Industry data from the Fluid Power Journal indicates that improperly sized pumps can lead to decreased efficiency, leading to increased operational costs.

Tip: Always consult with a pump specialist to match the pump size with your application's flow rate and pressure requirements.

Lastly, consider the pump design and maintenance needs. Diaphragm pumps come in various configurations, each suited to different applications, such as food processing, chemicals, or waste management. A study by the American Society of Mechanical Engineers suggests that ease of maintenance should be a priority, as pumps requiring extensive disassembly can lead to downtime and increased maintenance costs.

Tip: Investigate pumps with user-friendly designs that simplify maintenance procedures, potentially reducing overall operational costs.

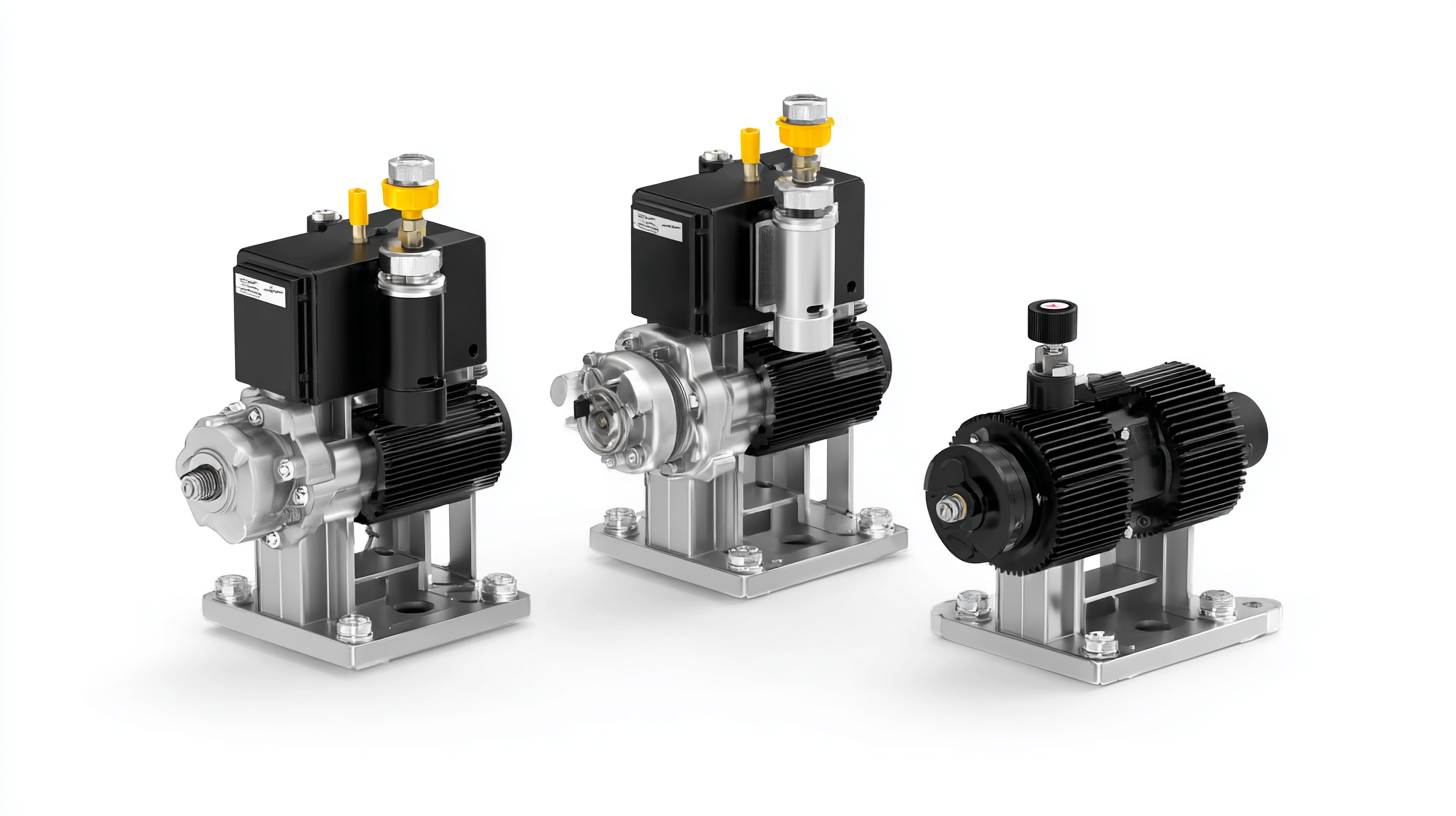

Comparing Different Types of Diaphragm Pumps for Specific Applications

When choosing an air operated diaphragm pump, it's essential to consider the specific applications it will serve. There are several types of diaphragm pumps available, including traditional elastomeric, PTFE-coated, and non-metallic designs. Each type caters to distinct needs based on factors like chemical compatibility, flow rate, and pressure requirements. According to a report from Research and Markets, the global diaphragm pump market is projected to reach $6.8 billion by 2025, indicating the rising demand for tailored solutions across various industries.

In the chemical processing sector, for example, PTFE-coated diaphragm pumps are favored due to their superior chemical resistance and ability to handle corrosive substances. A study by Transparency Market Research highlighted that these pumps can efficiently deliver up to 100 gallons per minute (GPM) at pressures exceeding 100 psi, making them ideal for rigorous applications.

Conversely, non-metallic diaphragm pumps are preferred in food and beverage industries due to their hygienic properties and compliance with FDA regulations, ensuring safe handling of consumables without contamination. Understanding the specific requirements of your application is crucial for optimizing pump performance and longevity.

Tips for Sizing Your Air Operated Diaphragm Pump Correctly

Choosing the right air operated diaphragm pump requires careful consideration of sizing to ensure optimal performance for your specific applications. The first step in sizing your pump is to accurately assess your flow requirements. Determine the flow rate needed for your operation, typically measured in gallons per minute (GPM) or liters per minute (LPM). Understanding the viscosity of the fluid you'll be pumping is also crucial, as thicker fluids require more powerful pumps and potentially larger diaphragm sizes to maintain efficiency.

Next, it's essential to consider the lift and pressure requirements for your application. The pump must have the capability to handle the required suction lift and discharge pressure. Calculate the total dynamic head (TDH) to ensure the pump can effectively move the fluid through the system. Additionally, consider the potential for variations in flow demands during operation, which may necessitate a pump with a wider capacity range or adjustable flow settings. By paying close attention to these factors, you can select an air operated diaphragm pump that not only meets your current needs but also adapts to future changes in your operational requirements.

How to Choose the Right Air Operated Diaphragm Pump for Your Applications - Tips for Sizing Your Air Operated Diaphragm Pump Correctly

| Pump Size (inch) | Max Flow Rate (GPM) | Max Pressure (psi) | Fluid Viscosity (cP) | Recommended Applications |

|---|---|---|---|---|

| 1/4 | 5 | 60 | 500 | Chemical transfer, coatings |

| 1/2 | 10 | 80 | 1000 | Wastewater, food processing |

| 3/4 | 15 | 100 | 1500 | Oil transfer, high viscosity fluids |

| 1 | 25 | 120 | 2000 | Paint, adhesives, slurries |

| 1.5 | 40 | 150 | 2500 | Bulk material handling, drum pumps |

Maintenance Best Practices for Longevity of Diaphragm Pumps

When it comes to maintaining diaphragm pumps, following best practices is essential for ensuring their longevity and performance. Regular inspections are critical; check for signs of wear, leaks, and proper alignment to avoid any potential issues. Moreover, it's important to keep the pump clean and free from blockages. Dust, debris, and sediment can not only hinder performance but also lead to premature failure if left unchecked.

Tips for efficient operation include using the correct fluid viscosity and ensuring that the pump is adequately lubricated. Flushing the diaphragm pump with clean water after each use can help prevent contamination and build-up of corrosive materials. Additionally, training operators on the proper use of the pump can drastically reduce mishandling that could result in increased wear or damage.

Investing time in these maintenance best practices not only enhances the performance of your diaphragm pump but also extends its operational life, making it a cost-effective solution in various industries. Remember, a well-maintained pump translates into improved efficiency and reliability for your applications.

Air Operated Diaphragm Pump Performance Comparison

Related Posts

-

How to Select the Right Diaphragm Pump for Your Industrial Needs

-

How to Select the Right Chemical Pump for Your Industrial Needs

-

Progressive Cavity Pumps Exposed: A Comprehensive Comparison of Efficiency and Cost-Effectiveness

-

How to Choose the Right Double Diaphragm Pump for Your Application

-

Ultimate Guide to Selecting the Right Fuel Transfer Tank with Pump: Expert Insights and Industry Standards

-

Top Strategies for Enhancing Efficiency with Metering Pumps