The Essential Guide to Choosing the Right Air Diaphragm Pump for Your Application Needs

When selecting the right air diaphragm pump for your application needs, it's essential to understand the various types available in the market. According to a report by MarketsandMarkets, the global diaphragm pump market is projected to reach $6.9 billion by 2026, growing at a CAGR of 4.5% from 2021. This growth reflects the increasing demand across various industries, including chemical processing, water and wastewater treatment, and pharmaceuticals, where air diaphragm pumps provide unique advantages such as self-priming capabilities and the ability to handle abrasive and viscous fluids.

Understanding the different types of air diaphragm pumps, including single and double diaphragm variations, is crucial for optimizing performance and ensuring reliable operation in your specific application. Thus, this guide aims to equip you with the necessary knowledge to make an informed decision when choosing the right air diaphragm pump for your needs.

Understanding the Basics of Air Diaphragm Pumps and Their Functionality

Air diaphragm pumps are versatile and efficient devices commonly used in various applications, such as chemical processing, water treatment, and food production. Understanding the basic components of these pumps is crucial for selecting the right model for your needs. At their core, air diaphragm pumps consist of two diaphragm chambers, an air control system, and inlet and outlet valves. The diaphragm is driven by compressed air, creating a pumping action that moves fluids through the system without the need for electrical power, making them an excellent choice for hazardous or remote environments.

The functionality of air diaphragm pumps is straightforward yet effective. When compressed air enters one chamber, it pushes the diaphragm to expel liquid from the opposing chamber, creating a continuous flow. This design allows for dry running capabilities and can handle a variety of fluids, including viscous or abrasive materials. Their design also minimizes maintenance requirements, as they are less prone to wear compared to traditional pumps. By grasping the fundamentals of how air diaphragm pumps operate, users can better evaluate their options and choose a model tailored to their specific application.

The Essential Guide to Choosing the Right Air Diaphragm Pump

This chart illustrates the performance characteristics of different air diaphragm pump types based on their flow rate (GPM) and operating pressure (PSI). Choosing the right pump depends on understanding these metrics and how they align with your application needs.

Identifying Key Application Requirements for Optimal Pump Selection

When selecting an air diaphragm pump for your specific application, identifying key requirements is crucial for optimal performance. Start by assessing the materials that the pump will handle. Different fluids, such as corrosive chemicals or food-grade substances, necessitate materials that can withstand specific conditions. Understanding the compatibility of the pump materials with the fluids will prevent premature wear and ensure safety.

Another important factor to consider is the flow rate needed for your application. Different pumps offer varying flow rates, so it’s essential to analyze the demands of your system. If the flow rate is too low, operations may become inefficient; conversely, a pump with an excessively high flow rate can cause product damage or system issues.

Tip: Make a list of your application’s requirements before shopping for a pump, including flow rate, pressure, and compatibility with the fluid. This will streamline your selection process and help you choose the most suitable pump for your needs.

Finally, consider the operational environment. Factors like temperature fluctuations and space constraints can influence the choice of pump. Ensure that the pump you select can operate efficiently in the conditions it will encounter, and that it fits within the available space.

Tip: Review the manufacturer’s specifications and consult with experts if unsure about which pump suits your application best. Proper research and consideration will lead to a more successful outcome.

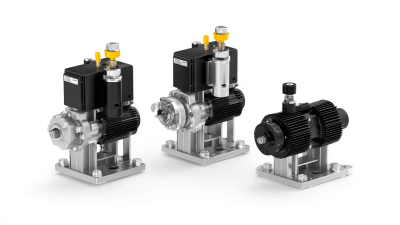

Comparing Different Types of Air Diaphragm Pumps Available in the Market

When selecting an air diaphragm pump for your application, it's crucial to understand the various types available in the market. Generally, air diaphragm pumps can be categorized into two primary types: traditional and sanitary.

On the other hand, sanitary air diaphragm pumps are specifically engineered for applications in the food, pharmaceutical, and biotechnology industries. These pumps meet stringent hygiene standards and are constructed from materials that prevent contamination. Sanitary pumps often include features such as easy-to-clean surfaces and minimal dead legs, ensuring that they maintain product integrity throughout the pumping process. When comparing these two types of pumps, it is essential to weigh factors such as fluid characteristics, required flow rates, and cleanliness standards to ensure that you choose the right pump for your specific needs.

Evaluating Performance Factors: Pressure, Flow Rate, and Material Compatibility

When selecting the right air diaphragm pump for your specific application, evaluating performance factors such as pressure, flow rate, and material compatibility is crucial. Pressure rating is a primary consideration; most diaphragm pumps operate effectively at pressures between 60 psi to 120 psi, while some models can handle up to 200 psi. Understanding the pressure requirements of your application can help ensure optimal performance and prevent damage to the pump.

Flow rate is another essential criterion, as it directly influences the efficiency of your processing operation. Typical flow rates for air diaphragm pumps range from 0.5 to 40 gallons per minute (GPM). For example, a 1-inch pump can deliver around 25 GPM at maximum efficiency under ideal conditions. Ensuring that the pump's flow rate aligns with your operational needs helps maintain consistent productivity.

Tips: Before making a decision, always check the material compatibility of the pump with the fluids you'll be working with; certain materials may degrade or react adversely with specific liquids, leading to costly downtime. Additionally, consider the installation environment—pumps designed for corrosive environments may be necessary for applications involving aggressive chemicals.

Maintenance Tips to Enhance Longevity and Efficiency of Your Pump

When it comes to ensuring the longevity and efficiency of your air diaphragm pump, regular maintenance is key. One of the most important tips for upkeep is to routinely check and replace worn-out seals and diaphragms. Over time, these components can deteriorate, leading to leaks and reduced performance. By scheduling regular inspections and replacing parts as needed, you can prevent larger issues that may arise from neglect.

Another critical aspect of maintenance is ensuring proper lubrication. Keeping moving parts well lubricated can minimize wear and tear, enhancing the pump's efficiency. Consider using a high-quality lubricant specifically designed for air diaphragm pumps. Additionally, maintaining clean air supply lines is essential, as contaminants can affect pump performance and lead to premature failure. Regularly purging any accumulated dirt or moisture helps maintain optimal operation.

Lastly, pay attention to the air pressure settings. Operating the pump at recommended pressure levels ensures efficient performance and extends its lifespan. Over-pressurizing can strain the system and result in costly repairs. By incorporating these tips into your maintenance routine, you can enhance the longevity and efficiency of your air diaphragm pump, ensuring it meets your application needs effectively.

Related Posts

-

How to Select the Right Diaphragm Pump for Your Industrial Needs

-

How to Choose the Right Air Operated Diaphragm Pump for Your Applications

-

Why Understanding Diesel Tanks is Essential for Your Business Operations

-

Innovations in Fuel Storage Tanks Showcased at the 138th Canton Fair in 2025

-

How to Choose the Right Chemical Dosing Pump for Your Industrial Needs

-

How to Choose the Right Fuel Transfer Tank with Pump for Your Needs