How to Choose the Right Transfer Tank Pump for Your Needs in 2025

In the ever-evolving landscape of fuel transport and storage, the choice of a transfer tank pump is critical to ensuring safety, efficiency, and reliability. As we approach 2025, advancements in technology and increased awareness of environmental impact make it imperative for users to carefully consider their options. A transfer tank pump is essential for transporting fuel from storage tanks to vehicles or equipment, and selecting the right one can significantly affect both performance and operational costs.

When navigating the myriad of choices available today, it's vital to understand the key factors that influence the functionality and suitability of a transfer tank pump. Considerations such as flow rate, pump type, material compatibility, and safety features play an essential role in matching a pump to specific needs. Additionally, the rising importance of compliance with industry standards and environmental regulations cannot be overlooked. This comprehensive guide will equip users with the knowledge needed to make informed decisions, ensuring that they choose a transfer tank pump that meets their requirements while optimizing efficiency and adhering to safety protocols in 2025 and beyond.

Understanding Transfer Tank Pumps: Types and Mechanisms

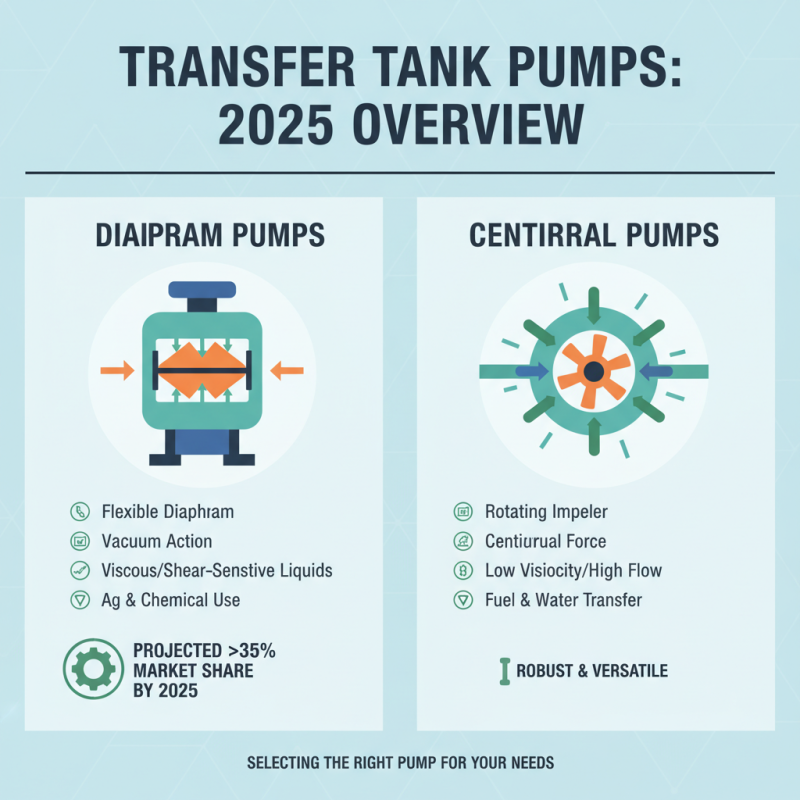

Transfer tank pumps are essential devices used for moving and transferring liquids from one container to another, and understanding their types and mechanisms is crucial for selecting the right pump for your needs in 2025. There are generally two primary types of transfer tank pumps: diaphragm pumps and centrifugal pumps. Diaphragm pumps utilize a flexible diaphragm to create a vacuum that moves fluids. They are particularly suitable for transferring viscous or shear-sensitive materials, making them a popular choice in various agricultural and chemical applications. According to a recent industry report, diaphragm pumps are projected to capture over 35% of the market share by 2025, due to their robust design and versatility.

Centrifugal pumps, on the other hand, rely on rotational energy to transfer liquids. They are widely used in scenarios requiring high flow rates and lower viscosity liquids, such as diesel and water. The pumping mechanism operates by increasing the velocity of the fluid with a rotating impeller, converting that velocity into pressure. With an estimated growth of 5.5% annually through 2025, centrifugal pumps are favored in construction and infrastructure applications due to their efficiency and ability to handle large volumes. Understanding these mechanisms and the types of pumps available will aid in making informed decisions tailored to specific operational needs, ensuring efficiency and reliability in transfer applications.

Key Factors to Consider When Choosing a Transfer Tank Pump

When selecting a transfer tank pump in 2025, it’s crucial to evaluate several key factors to ensure you choose one that meets your specific needs. First, consider the pump's flow rate, which determines how quickly you can transfer liquids. Depending on your application, you may require a pump that can handle higher volumes efficiently without compromising performance. Additionally, compatibility with your transfer tank and the types of fluids you intend to move is essential. Make sure the pump materials are suitable for the substances, as this will influence durability and effectiveness.

Tips: Before purchasing a transfer tank pump, take the time to assess your required flow rate based on your typical usage scenarios. Measure the container capacity and expected transfer frequency to find a pump that aligns perfectly with your daily operations.

Another vital factor is the power source; pumps can be powered by electricity, battery, or even manual operation. Understanding your available power options will guide you in selecting a pump that can be conveniently operated under your working conditions. Furthermore, consider additional features such as automatic shut-off systems or hose length, as these can enhance safety and usability.

Tips: Always read reviews and feedback from other users regarding the pump’s performance in real-world applications. This can provide insight into reliability and efficiency that technical specifications alone may not reveal.

How to Choose the Right Transfer Tank Pump for Your Needs in 2025

| Feature | Description | Importance Level | Recommended Type |

|---|---|---|---|

| Flow Rate | The speed at which the pump can transfer fuel, measured in gallons per minute (GPM). | High | Electric Pumps |

| Power Source | Indicates whether the pump operates on electricity, battery, or combustion engine. | Medium | Solar/Battery Pumps |

| Pump Size | Dimensions of the pump, important for compatibility with existing equipment. | Medium | Compact Pumps |

| Material Compatibility | The type of fluid the pump can handle without degradation. | High | Aluminum/Stainless Steel Pumps |

| Portability | Ease of moving the pump from one location to another. | Medium | Portable Pumps |

| Safety Features | Includes automatic shut-off, leak detection, and explosion-proof design. | High | Pumps with Safety Features |

Performance Metrics: Flow Rate and Pressure in Transfer Tank Pumps

When selecting a transfer tank pump, understanding performance metrics such as flow rate and pressure is essential for making an informed choice. The flow rate, measured in gallons per minute (GPM), refers to the speed at which the pump can transfer liquids. Depending on the application, different flow rates may be necessary. For instance, if you require rapid dispensing for large equipment, a higher flow rate is beneficial. Conversely, if precision and control are paramount, a pump with adjustable flow capabilities might be more appropriate.

Pressure is another critical factor that influences the efficiency of a transfer tank pump. Measured in pounds per square inch (PSI), the pressure determines the pump's ability to move liquids through hoses and into specific containers. Higher pressure can be advantageous for overcoming resistance in longer or narrower hoses, but it should be balanced with the specific requirements of the liquid being transferred. Understanding both flow rate and pressure enables users to choose pumps that align with the demands of their applications, ensuring optimal performance and reliability in 2025 and beyond.

Durability and Safety Standards: Ensuring Quality in 2025 Models

Selecting the right transfer tank pump involves a thorough understanding of the durability and safety standards that are critical in 2025 models. According to the National Fire Protection Association (NFPA), compliance with safety standards is paramount, particularly for equipment that handles flammable liquids. In their latest report, the NFPA highlighted that over 40% of incidents involving transfer pumps are related to equipment failure due to subpar manufacturing standards. Therefore, investing in pumps that meet or exceed the latest safety regulations, such as those outlined by the American Society for Testing and Materials (ASTM), is essential for ensuring longevity and operational safety.

Durability in pump design not only enhances performance but also reduces long-term costs associated with maintenance and replacements. Research from the American Pump Manufacturers Association indicates that pumps designed with advanced materials and corrosion resistance show a lifespan increase by up to 30% compared to standard models. When choosing a pump, it's crucial to consider features that can enhance durability, such as protective casings, high-quality seals, and robust motor designs. As the industry evolves, the emphasis on stronger safety features, such as automatic shut-off mechanisms and better filtration systems, will enhance both user safety and equipment reliability, making it a vital aspect of your purchasing decision in 2025.

Cost Analysis: Budgeting for Transfer Tank Pumps and Maintenance

When budgeting for a transfer tank pump, it's essential to consider both the initial purchase price and the ongoing maintenance costs. Prices can vary widely based on the pump's size, capacity, and features. A basic model might start at a few hundred dollars, while more advanced pumps can reach into the thousands. It's wise to allocate a portion of your budget for unexpected repairs or replacements, as regular maintenance can help extend the life of your equipment and prevent costly issues down the line.

Tips: Always research the specifications and features that best suit your requirements before making a purchase. Additionally, establishing a routine maintenance schedule can minimize downtime and ensure your pump operates efficiently.

In addition to the upfront costs, consider the long-term value of energy efficiency and durability. Some pumps may be more expensive initially but could save you money on fuel and utilities over their lifespan. It's crucial to analyze the total cost of ownership, taking into account not just the purchase price, but also the maintenance, repair costs, and energy consumption to make an informed decision that fits your budget and needs effectively.

Cost Analysis of Transfer Tank Pumps and Maintenance (2025)

Related Posts

-

Everything You Need to Know About Transfer Tank Pumps: Your Ultimate Guide to Safe Fuel Handling

-

How to Choose the Right Gas Transfer Pump for Your Needs

-

7 Reasons to Choose a Diesel Transfer Tank with Pump for Your Business

-

How to Choose the Right Fuel Transfer Tank with Pump for Your Needs

-

How to Select the Right Chemical Pump for Your Industrial Needs

-

How to Choose the Right Chemical Pump for Your Industry Needs