How to Choose the Right Double Diaphragm Pump for Your Needs?

When selecting a double diaphragm pump, understanding your specific needs is essential. These pumps offer unique advantages for various applications. However, choosing the right one can be overwhelming. Many factors play a role in this decision.

Different industries utilize double diaphragm pumps for diverse purposes. For example, they are effective in transferring corrosive fluids. Yet, each situation requires careful consideration of material compatibility and flow rates. Some users struggle to identify the best options for their projects. Frustration can arise when faced with so many choices.

While seeking the ideal double diaphragm pump, it is vital to consider your operational environment. Factors like temperature and viscosity matter. An incorrect choice can lead to inefficient performance or pump failure. Taking time to reflect on your requirements will pay off. Ultimately, the right selection will enhance productivity and ensure reliability in your processes.

Understanding the Basics of Double Diaphragm Pumps

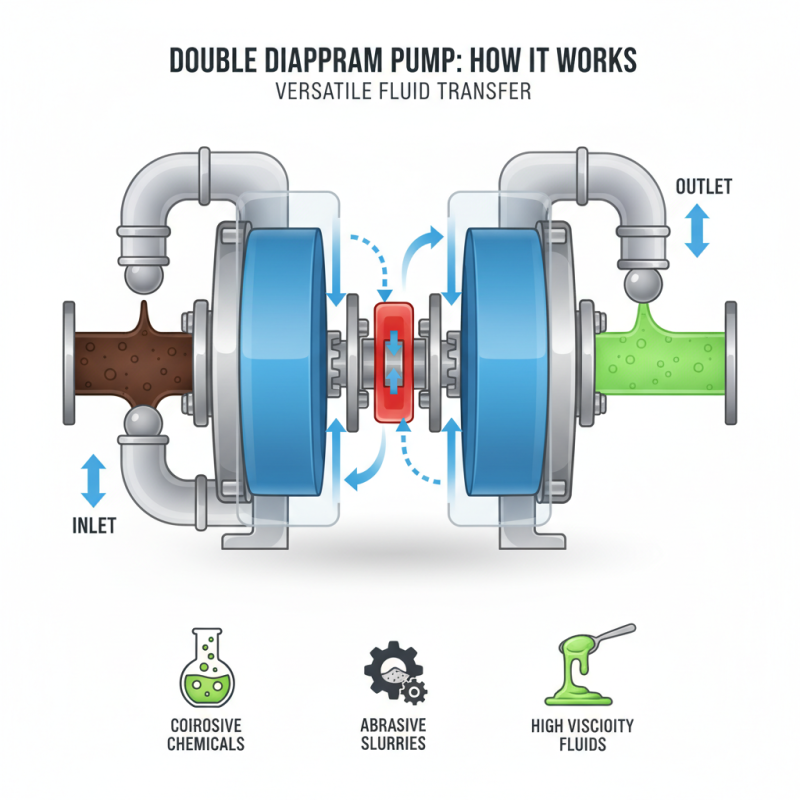

Double diaphragm pumps are versatile tools used across various industries. They operate on a simple principle: the movement of two diaphragms creates a suction effect. This allows fluids to be drawn in and expelled easily. Their design makes them suitable for handling thick, corrosive, or abrasive materials. However, choosing the right pump requires careful consideration of specific needs.

Not all double diaphragm pumps are the same. Factors such as flow rate and pressure requirement play a crucial role. A pump with too high a flow rate can lead to wastage or inefficiency. On the other hand, an underperforming pump may struggle with the demands of your application. Keep in mind the fluid types as well. Some fluids can damage poorly selected materials. This oversight can lead to costly repairs or replacements.

Understanding your application is essential. Gather data on the materials you intend to pump. Evaluate the environmental conditions where the pump will operate. A poorly matched pump can suffer from priming issues or frequent maintenance. Reflecting on these factors will lead to better decisions and improved efficiency in your operations.

Key Factors to Consider When Selecting a Double Diaphragm Pump

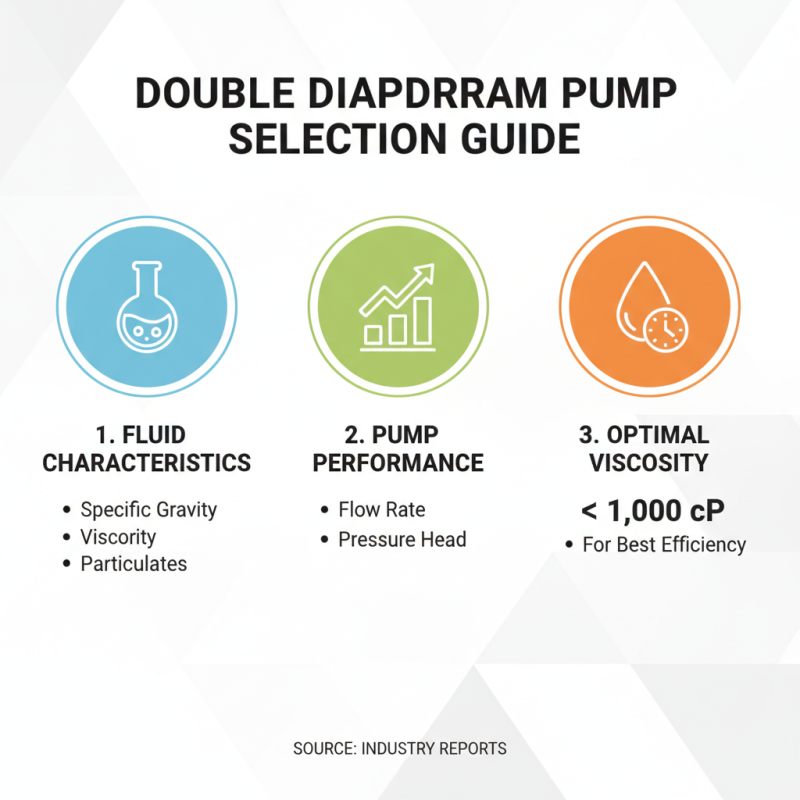

When selecting a double diaphragm pump, there are several key factors to consider. Understanding the fluid characteristics is crucial. Specific gravity, viscosity, and any particulates in the fluid can significantly affect pump performance. According to industry reports, pumps perform best when fluid viscosity stays below 1,000 cP for optimal efficiency.

Another important factor is the required flow rate and pressure. You need to determine the maximum flow required for your application. Many users overlook this, resulting in undersized or oversized pumps. A study indicated that 30% of breakdowns are related to improper sizing. This can lead to costly downtime.

**Tip:** Always consult pump performance charts provided by manufacturers. These charts show the relationship between flow rate and discharge pressure, allowing for a more informed decision.

Material compatibility also plays a vital role. Different materials can withstand varying chemical compositions. For instance, certain plastics may not hold up against solvents, leading to potential failures. Consider also how temperature changes might affect your pump's materials.

**Tip:** Conduct a simple compatibility test with your actual fluids before making a final decision. This can prevent future headaches and costs.

Evaluating Material Compatibility for Your Pumping Applications

When selecting a double diaphragm pump, material compatibility is critical. The type of material used in the pump can greatly affect its performance. For instance, according to a 2021 report by the Fluid Handling Institute, over 30% of pump failures are attributed to material incompatibility. This can lead to leaks, inefficiencies, and increased maintenance costs.

Consider the substances being pumped. Corrosive chemicals like acids and solvents require specific materials. While some pumps may handle water well, they could fail when exposed to harsh chemicals. This mismatch often results in expensive repairs or replacement. Additionally, a study published in the Journal of Pump Technology highlighted that 60% of operators underestimated the importance of material selection, leading to operational disruptions.

Evaluate factors such as temperature and pressure. High temperatures can weaken certain materials, while high pressures may exacerbate wear. Polypropylene may be good for some applications, but in extreme conditions, it might lose integrity. It's crucial to know the physical and chemical properties of both the fluid and the pump material. This understanding can help prevent costly mistakes and ensure long-term reliability.

Assessing Flow Rate and Pressure Requirements

When selecting a double diaphragm pump, assessing flow rate and pressure is crucial. Flow rate determines how much liquid can be moved within a specific time. If the flow rate is too low, processes slow down. Conversely, an excessively high flow rate could lead to instability and control issues. It’s essential to calculate your needs carefully, often with real-life testing.

Pressure requirements play a vital role too. Each application has different pressure needs. Too much pressure can damage your pump or the system. Too little pressure might result in insufficient flow. Consider the type of liquid being pumped. Viscosity can affect how pressure is applied. High viscosity fluids often require more pressure for the same flow rate.

It's not always easy to balance these factors. Mistakes in evaluating flow and pressure can lead to operational failures. Sometimes, users may not realize the importance of testing under real conditions. Gather data from your actual applications whenever possible. This will inform your choice more accurately than theoretical calculations alone. Reflect on past experiences and learn from them.

Maintenance and Longevity Considerations for Double Diaphragm Pumps

When considering the maintenance and longevity of double diaphragm pumps, proper care is crucial. Regular inspections can reveal early signs of wear. Pay attention to the diaphragm material. Different substances react differently with various fluids. Ensure your pump is compatible with the fluids it handles.

Over time, components may degrade. Check for leaks or unusual vibrations. These are often signs that parts need replacing. Regularly clean the pump. This helps prevent buildup that can hinder performance. A clean pump operates more efficiently and lasts longer.

It’s also essential to follow the manufacturer’s guidelines. However, not every situation is straightforward. Some operators may skip certain steps, thinking they are unnecessary. This can lead to unexpected issues. Investing time in maintenance can save money in the long run. Consider setting up a routine schedule for checks and maintenance. It can help identify problems before they escalate.

How to Choose the Right Double Diaphragm Pump for Your Needs? - Maintenance and Longevity Considerations for Double Diaphragm Pumps

| Dimension | Value |

|---|---|

| Pump Type | Air-Operated Double Diaphragm (AODD) |

| Flow Rate | 5 - 200 GPM |

| Maximum Pressure | 100 PSI |

| Diaphragm Material | Polyurethane, PTFE |

| Applications | Chemical Transfer, Sludge Handling, Paints & Coatings |

| Maintenance Frequency | Every 6 months |

| Average Lifespan | 5 - 10 years |

| Weight | 50 - 150 lbs |

| Installation Type | Floor Mounted, Portable |

Related Posts

-

How to Select the Right Diaphragm Pump for Your Industrial Needs

-

The Essential Guide to Choosing the Right Air Diaphragm Pump for Your Application Needs

-

How to Choose the Right Air Operated Diaphragm Pump for Your Applications

-

Exploring the Benefits of Air Operated Diaphragm Pumps: A Comprehensive Guide for Industrial Applications

-

Unleashing the Power of Air Diaphragm Pumps: How They Revolutionize Fluid Handling in Various Industries

-

Unlocking Efficiency: The Advantages of Advanced Fuel Storage Tanks for Your Business