How to Choose the Right Chemical Dosing Pump for Your Industrial Needs

In the industrial sector, the selection of the appropriate chemical dosing pump is crucial for optimizing operational efficiency and ensuring regulatory compliance. According to a recent report by MarketsandMarkets, the global chemical dosing pump market is projected to reach USD 4.3 billion by 2026, growing at a CAGR of 4.8% from 2021 to 2026. This growth underscores the increasing demand for precise and reliable dosing in various applications, including water treatment, chemical processing, and pharmaceuticals. A well-chosen chemical dosing pump can significantly impact overall productivity and safety, addressing the distinct needs of each industry while reducing waste and enhancing performance.

As businesses navigate through diverse options and technological advancements, understanding the key factors in selecting the right pump becomes paramount for achieving optimal results in their operations.

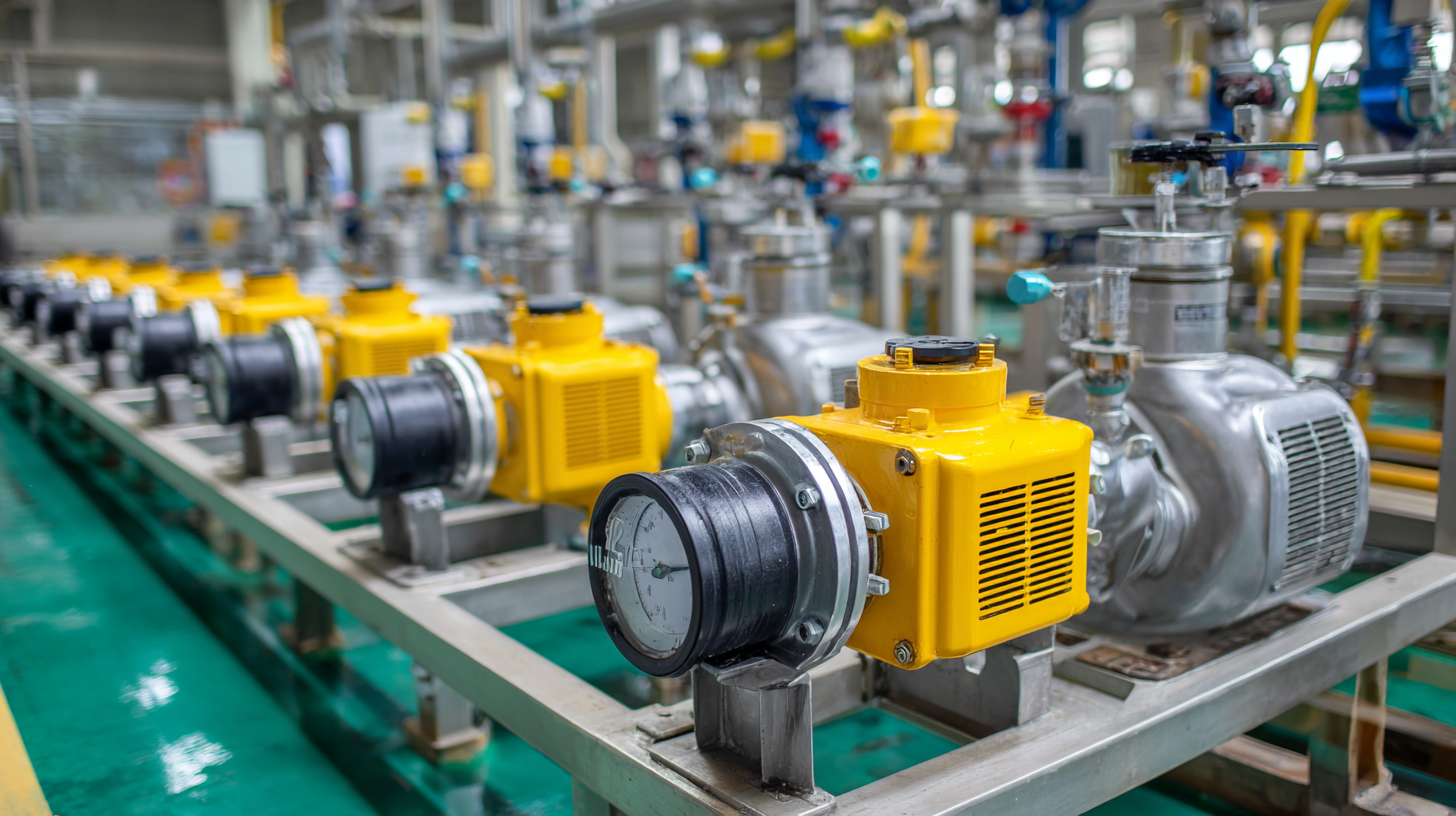

Types of Chemical Dosing Pumps: An Overview

When selecting a chemical dosing pump for industrial applications, it's essential to understand the various types available and their respective functionalities. Generally, chemical dosing pumps can be classified into categories such as diaphragm pumps, peristaltic pumps, and gear pumps. According to a report by MarketsandMarkets, the global chemical dosing pump market is expected to reach USD 5.15 billion by 2023, driven by their increasing demand across water treatment, oil and gas, and food and beverage industries.

Diaphragm pumps are particularly popular due to their accuracy and ability to handle corrosive chemicals without leakage, making them ideal for applications in chemical manufacturing. Peristaltic pumps, on the other hand, are known for their ease of maintenance and flexibility when it comes to dosing varying chemical viscosities. A recent study from Research and Markets indicates that the peristaltic pump segment is anticipated to grow significantly, owing to its expanding usage in pharmaceuticals and biotechnology sectors.

Diaphragm pumps are particularly popular due to their accuracy and ability to handle corrosive chemicals without leakage, making them ideal for applications in chemical manufacturing. Peristaltic pumps, on the other hand, are known for their ease of maintenance and flexibility when it comes to dosing varying chemical viscosities. A recent study from Research and Markets indicates that the peristaltic pump segment is anticipated to grow significantly, owing to its expanding usage in pharmaceuticals and biotechnology sectors.

Gear pumps offer precise flow control and are typically used for high-pressure applications. As highlighted in a report from Grand View Research, the robustness and efficiency of gear pumps make them a preferred choice in industrial settings requiring continuous operation. Understanding these types of pumps, along with their specific advantages, can significantly enhance operational efficiency and safety in various industrial processes.

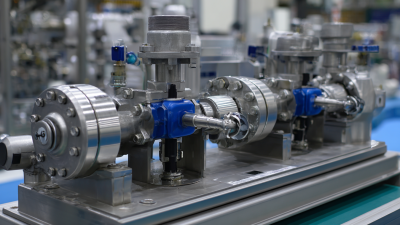

Key Factors for Selecting the Right Pump Type

When selecting the right chemical dosing pump for industrial applications, several key factors must be considered to ensure optimal performance and efficiency. Primarily, the pump's chemical compatibility is crucial; materials must withstand the corrosive nature of the fluids being pumped. According to a report by the Chemical Engineering magazine, approximately 30% of pump failures in industrial settings are attributed to material incompatibility, leading to costly downtimes and repairs. Thus, understanding the chemical properties of the fluids and the compatibility of the pump materials can significantly enhance reliability.

Another important factor is the flow rate and dosing accuracy required for your specific application. As highlighted in the 2022 Fluid Handling report, industries that use precise chemical dosing, such as water treatment and pharmaceuticals, typically require pumps with an accuracy rating better than ±1%. This level of precision ensures compliance with regulatory standards and minimizes wastage, ultimately leading to cost savings. Additionally, evaluating the pump size and installation space is essential, as these factors will influence the choice between diaphragm pumps, peristaltic pumps, or others based on your site’s layout and operational needs.

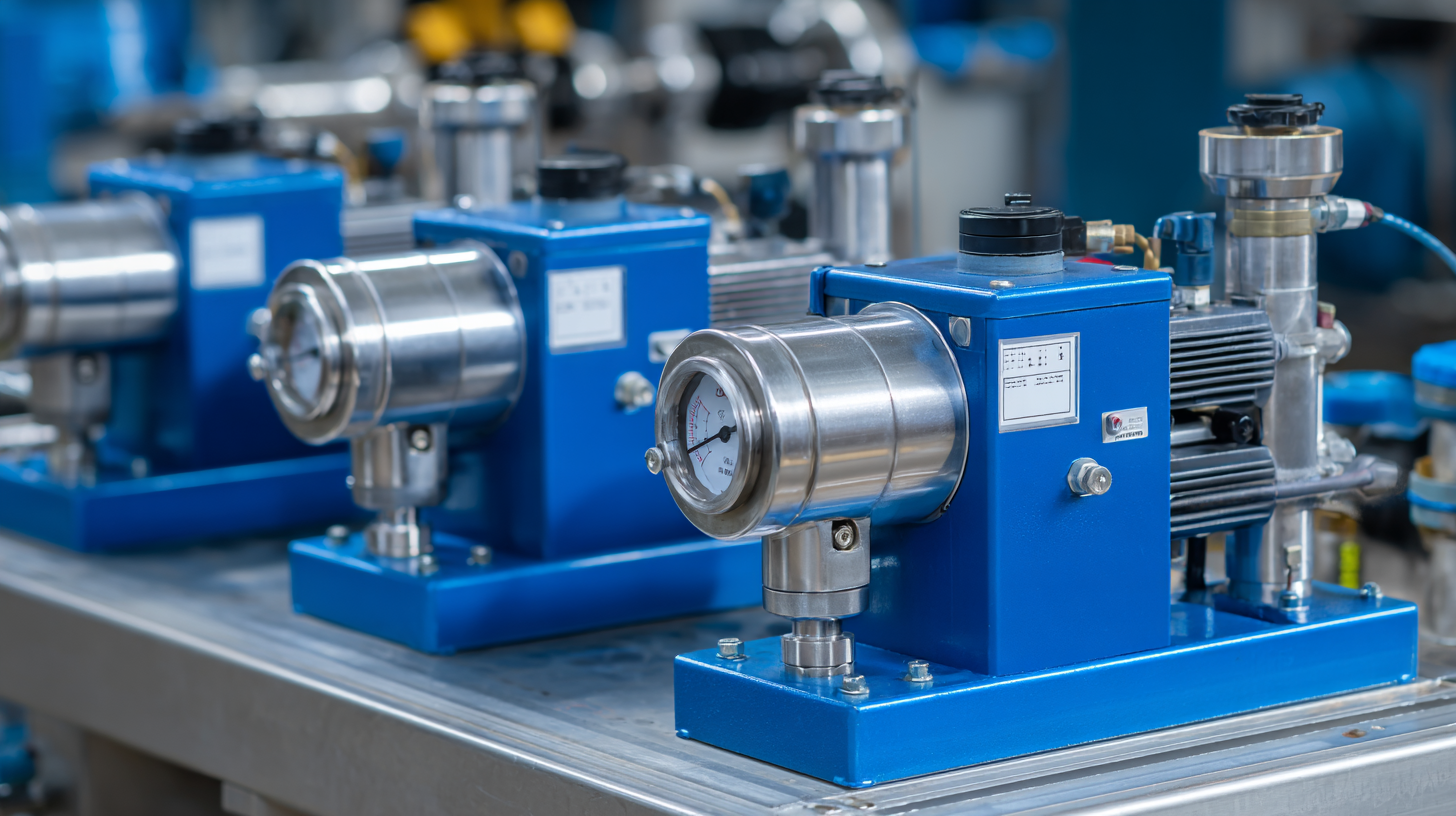

Comparison of Diaphragm vs. Peristaltic Dosing Pumps

When selecting a chemical dosing pump for industrial applications, understanding the differences between diaphragm and peristaltic dosing pumps is crucial. Diaphragm pumps are known for their ability to handle corrosive chemicals and provide high precision in dosing with minimal leakage. According to a recent report by MarketsandMarkets, the global diaphragm pump market is projected to reach $5.45 billion by 2025, driven by their efficiency and reliability in challenging environments. This makes them ideal for chemical processing industries where safety and accuracy are paramount.

On the other hand, peristaltic pumps offer distinct advantages, particularly in applications requiring gentle handling of fluids and easy maintenance. The fluid never comes into direct contact with the pump mechanism, reducing wear and minimizing contamination risk. The global peristaltic pump market is expected to grow at a CAGR of 5.4% from 2020 to 2027, as highlighted in the latest Grand View Research report. This growth can be attributed to the increasing demand in pharmaceutical and biotechnology sectors, where precision and sterile conditions are essential.

Ultimately, the choice between diaphragm and peristaltic dosing pumps hinges on specific application requirements, including chemical compatibility, flow rates, and maintenance considerations, making it essential for industries to evaluate their needs meticulously.

How to Choose the Right Chemical Dosing Pump for Your Industrial Needs - Comparison of Diaphragm vs. Peristaltic Dosing Pumps

| Feature | Diaphragm Pump | Peristaltic Pump |

|---|---|---|

| Flow Rate Range | Up to 160 GPH | Up to 350 GPH |

| Pressure Capability | Up to 100 PSI | Up to 30 PSI |

| Viscosity Handling | Low to medium viscosity | High viscosity |

| Self-Priming | Yes | Yes |

| Maintenance | Moderate | Low |

| Cost | Moderate | Low to moderate |

| Typical Applications | Water treatment, chemical processing | Food processing, pharmaceuticals |

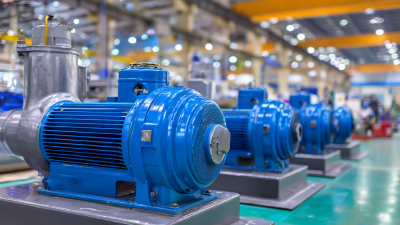

Understanding Flow Rates and Pressure Requirements

When selecting the right chemical dosing pump for your industrial needs, understanding flow rates and pressure requirements is crucial. Flow rate, typically measured in liters per hour (L/h) or gallons per minute (GPM), indicates how much fluid the pump can deliver within a specific timeframe. According to a recent report from MarketsandMarkets, the global dosing pump market is projected to grow at a CAGR of 6.3% from 2021 to 2026, driven largely by the increasing demand in water treatment and chemical processing industries. Thus, ensuring you choose a pump that can match the required flow rate is essential for operational efficiency.

Pressure requirements are equally important, as they affect the pump's ability to deliver chemicals to various points in the process. Pumps must be able to handle the system's maximum and minimum pressure conditions without failing. The Hydraulic Institute suggests that a pressure rating at 1.5 times the system pressure will enhance reliability and performance. While high pressure can facilitate dosing in intricate systems, it may also increase the risk of leaks and failures if not properly managed. Therefore, careful consideration of both flow rates and pressure conditions will lead to optimized performance in your chemical dosing applications.

Chemical Dosing Pump Flow Rates and Pressure Requirements

This chart illustrates the optimal flow rates and pressure requirements for various types of chemical dosing pumps used in industrial applications. Understanding these parameters helps in selecting the right pump for specific needs.

Application-Specific Considerations for Chemical Dosing Pumps

When selecting a chemical dosing pump for industrial applications, it is crucial to consider the specific requirements of the application at hand. Factors such as the type of chemicals being dosed, their viscosity, and corrosiveness can greatly influence the choice of pump. For instance, certain chemicals may require pumps made from specialized materials that can withstand harsh conditions without degrading. Additionally, understanding the flow rate and pressure requirements is essential to ensure that the pump can deliver the desired amount of chemical consistently and accurately.

Another significant consideration is the operational environment in which the dosing pump will be used. Factors such as temperature fluctuations, the presence of dust or moisture, and potential exposure to other chemicals can impact the pump’s performance and lifespan. For example, a pump used in a humid environment may need to have extra protection against moisture, while those in a dusty area might require enhanced sealing features. By carefully evaluating these application-specific factors, industries can select a dosing pump that not only meets their chemical handling needs but also ensures efficiency and safety in their processes.

Related Posts

-

Mastering Dosing Pumps: A Step-by-Step Guide to Optimal Use and Maintenance

-

Top Strategies for Enhancing Efficiency with Metering Pumps

-

How to Choose the Right Double Diaphragm Pump for Your Application

-

How to Choose the Right Gas Transfer Pump for Your Industrial Needs

-

How to Choose the Right Centrifugal Pump for Your Industrial Needs

-

Understanding the Benefits of Using Above Ground Diesel Storage Tanks in Various Industries