How to Choose the Best Fuel Transfer Tank with Pump for Your Needs

In today's fast-paced industrial environment, the efficient and safe transfer of fuels has become paramount. According to a recent report by the U.S. Energy Information Administration, the demand for effective fuel management solutions has increased significantly over the past decade, driven by the growth of sectors such as construction, agriculture, and transportation. This has elevated the importance of choosing the right fuel transfer tank with pump to ensure not only operational efficiency but also compliance with safety standards and regulations.

Fuel transfer tanks equipped with pumps provide a convenient solution for transporting and dispensing fuels, minimizing spills and contamination risks. The market for these tanks is predicted to grow significantly, with the global fuel transfer tank market projected to reach $1.5 billion by 2025, as highlighted in a comprehensive industry analysis. With various options available, selecting the ideal fuel transfer tank with pump involves careful consideration of factors such as capacity, portability, and material durability, ensuring it meets the specific needs of your operations without compromising safety or performance.

Understanding these key aspects will help businesses make informed decisions, maximizing productivity while safeguarding personnel and the environment. As the fuel transfer landscape continues to evolve, staying abreast of the latest innovations and industry standards will be crucial for those involved in fuel management.

Understanding Fuel Transfer Tanks: Types and Uses

Fuel transfer tanks are essential for a variety of industries and applications, ranging from agriculture to construction. These tanks can be classified mainly into two types:

portable and

stationary.

Portable fuel transfer tanks are designed for mobility and can be easily transported to various locations, making them ideal for construction sites or remote farming operations. According to a report by Grand View Research,

the demand for portable fuel tanks is expected to grow at a CAGR of 4.5% from 2023 to 2030, driven by the increasing need for efficient fuel distribution across different sectors.

On the other hand, stationary fuel tanks are typically installed in a fixed location and are suitable for larger operations that require a substantial fuel supply. These tanks often come with integrated pump systems for easy fuel dispensing.

The market for stationary fuel tanks is projected to expand as industries strive for more sustainable fuel solutions, as noted by a recent report from Markets and Markets. This report highlights a growing trend toward the use of

dual-purpose tanks that can accommodate both fuel and additives, which increases their applicability across various sectors while also enhancing safety and compliance with environmental regulations.

Understanding the specific needs of your operation, whether it be mobility or capacity, will be crucial in selecting the best fuel transfer tank for efficient and safe fuel handling.

Key Factors to Consider When Choosing a Fuel Transfer Tank

When choosing the best fuel transfer tank with a pump, there are several key factors to consider that can significantly impact efficiency and safety. First, assess your fuel storage capacity needs. According to the National Association of State Fire Marshals, over 70% of fuel transfer tank users select tanks ranging from 50 to 100 gallons. This range is often ideal for personal or small fleet use, but larger operations may require tanks holding up to 500 gallons. It's important to analyze not only how much fuel you typically need but also the frequency of refueling to determine the size that best suits your requirements.

Another critical factor is the construction material of the tank. Most fuel transfer tanks are made from either steel or polyethylene. Research from the American Petroleum Institute suggests that steel tanks tend to be more durable and resistant to puncture but are heavier and may rust over time. In contrast, polyethylene tanks are often lighter and corrosion-resistant, which makes them desirable for specific applications, especially in rugged environments. Additionally, consider the types of pumps available, as fuel pumps can vary in flow rates and power sources, with electric pumps generally providing faster fuel transfer. Understanding these factors will help ensure that your fuel transfer tank effectively meets your operational needs while adhering to safety standards.

Evaluating Pump Options for Your Fuel Transfer Needs

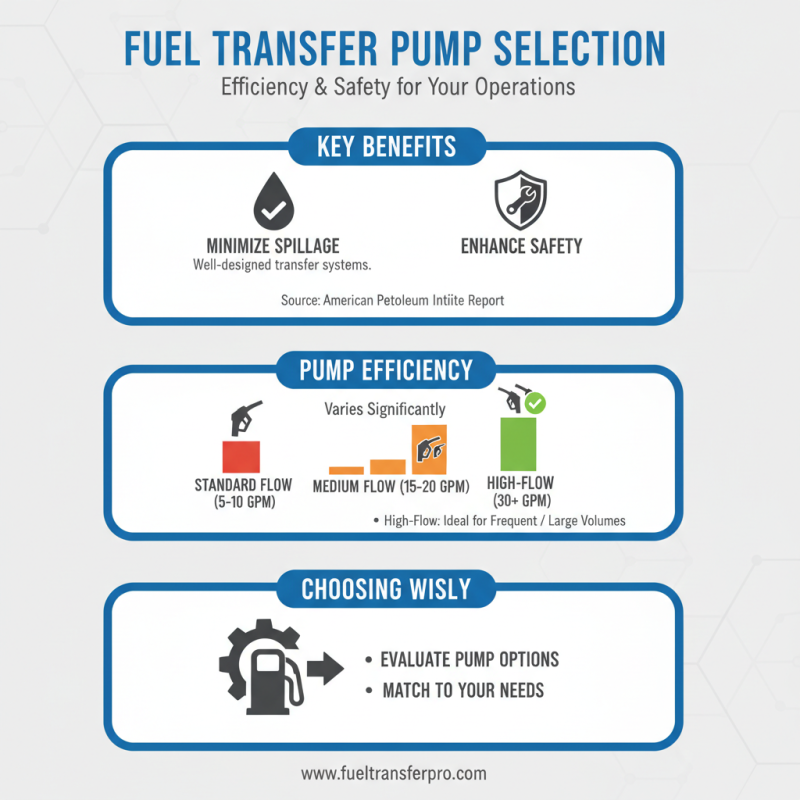

When selecting a fuel transfer tank with a pump, evaluating the pump options is crucial to ensuring efficiency and safety in your operations. A report from the American Petroleum Institute indicates that well-designed transfer systems can minimize spillage and reduce the risk of accidents, enhancing overall safety. The efficiency of various pumps varies significantly, with a high-flow pump capable of transferring fuel at rates exceeding 30 gallons per minute, which is ideal for frequent use and larger volumes.

When assessing pump types, consider factors such as flow rate, power source, and tank compatibility. Electric pumps are becoming increasingly popular due to their ease of use and maintenance, while manual pumps may offer greater portability and are preferable in remote locations. Understanding the specific requirements of your fuel transfer needs will guide you in making an informed decision.

**Tips:** Always ensure your pump’s specifications align with the fuel type and viscosity to avoid damage and inefficiency. Additionally, investing in an automatic shut-off feature can enhance safety by preventing overfilling. Lastly, regularly inspect and maintain your fuel transfer equipment to prolong its lifespan and optimize performance.

Safety Features to Look for in Fuel Transfer Tanks

When selecting a fuel transfer tank with a pump, one of the foremost aspects to consider is the safety features incorporated into the design. According to the American Petroleum Institute, over 50% of fuel spills are attributed to equipment failure or operator error. Thus, choosing a tank with robust safety measures can significantly mitigate risks. Look for tanks that are constructed with high-quality, corrosion-resistant materials, which are crucial for prolonging the lifespan of the tank and preventing unexpected leaks.

Additionally, consider fuel transfer tanks equipped with features such as automatic shut-off valves and overfill prevention systems. These innovations act as first lines of defense against overfilling and accidental spills. Reports from the U.S. Environmental Protection Agency emphasize that installations that include these safety features can reduce the likelihood of environmental contamination by up to 78%.

Tips: Always inspect the tank’s certification labels to ensure compliance with industry standards. Furthermore, consider tanks with built-in spill containment capabilities, which can further protect both the environment and your equipment from unforeseen accidents. Finally, ensure your fuel transfer tank is equipped with proper ventilation to prevent pressure buildup, an important factor often overlooked in safety considerations.

How to Choose the Best Fuel Transfer Tank with Pump for Your Needs

| Feature | Description | Importance |

|---|---|---|

| Material | Durable, corrosion-resistant materials like steel or aluminum. | High |

| Pump Type | Electric, manual, or battery-operated, suited for different needs. | Medium |

| Safety Features | Include anti-spill design, automatic shut-off, and grounding devices. | High |

| Capacity | Varies from small to large tanks based on usage needs. | Medium |

| Portability | Wheels or fixed designs for easy transport or installation. | Low |

| Ventilation | Proper ventilation to prevent pressure build-up. | High |

| Warranty | Check for a warranty period to cover defects or issues. | Medium |

Installation and Maintenance Tips for Fuel Transfer Systems

When installing a fuel transfer system, proper maintenance is crucial to ensure safety and efficiency. According to a report by the U.S. Department of Transportation, approximately 12% of fuel transfer incidents stem from improper installation or maintenance. Therefore, following manufacturer guidelines during setup is essential. Key installation tips include ensuring that all components are compatible, securely fastening connections to prevent leaks, and positioning the tank in a well-ventilated area to reduce the risk of vapor buildup.

Regular maintenance is equally important to keep the fuel transfer system in optimal condition. The National Fire Protection Association recommends that fuel transfer systems undergo inspections at least once a year. This includes checking for signs of wear or corrosion, testing the pump operation, and ensuring filters are replaced regularly. Implementing a maintenance schedule not only prevents unexpected breakdowns but also extends the lifespan of the equipment. By prioritizing installation and maintenance, operators can minimize risks and ensure smooth fuel transfer operations that meet productivity standards.

Related Posts

-

7 Reasons to Choose a Diesel Transfer Tank with Pump for Your Business

-

Ultimate Guide to Selecting the Right Fuel Transfer Tank with Pump: Expert Insights and Industry Standards

-

How to Choose the Right Fuel Transfer Tank with Pump for Your Needs

-

5 Best Diesel Fuel Tank Solutions for Your Business Efficiency

-

Everything You Need to Know About Transfer Tank Pumps: Your Ultimate Guide to Safe Fuel Handling

-

How to Choose the Best Diesel Transfer Tank with Pump for Your Needs in 2025