What is a Chemical Dosing Pump and How Does it Work for Your Needs

In the evolving landscape of industrial processes, the significance of precise chemical management has never been greater. A chemical dosing pump stands at the forefront of these advancements, enabling companies to deliver accurate amounts of chemicals in various applications, from water treatment facilities to food production systems. According to a recent report by MarketsandMarkets, the chemical dosing pump market is projected to grow from USD 3.1 billion in 2021 to USD 4.1 billion by 2026, driven by the increasing demands for efficient and sustainable operations across industries.

Experts emphasize the essential role of these pumps in ensuring both safety and efficacy. Dr. Jane Holloway, a renowned specialist in fluid dynamics, states, "The accuracy of a chemical dosing pump is crucial; even minor discrepancies can lead to significant operational inefficiencies." This highlights the necessity for rigorous selection and maintenance of dosing equipment, which not only facilitates compliance with environmental regulations but also optimizes production processes. As industries continue to leverage technology for enhanced performance, understanding the workings and applications of chemical dosing pumps becomes imperative for meeting the diverse needs of modern operations.

What is a Chemical Dosing Pump?

A chemical dosing pump is a specialized device designed to accurately deliver controlled amounts of chemicals into a process stream. These pumps play a crucial role in various industries, including water treatment, pharmaceutical manufacturing, and food production. According to a report by MarketsandMarkets, the global chemical dosing pump market is projected to reach $4.05 billion by 2025, driven by the rising demand for precision in chemical handling and increasing environmental regulations.

Chemical dosing pumps operate through a variety of mechanisms, including diaphragm, peristaltic, and gear-driven designs. They ensure consistent and accurate dosing, often critical for maintaining the desired chemical balance in treatment processes. For instance, in wastewater treatment plants, these pumps are essential for adding disinfectants or pH adjusters, which can significantly affect treatment efficiency and compliance with environmental standards. In fact, proper dosing can improve water quality by up to 30%, highlighting the importance of these systems in sustaining safe and efficient operations.

Additionally, chemical dosing pumps often feature adjustable flow rates and can be integrated with digital control systems for real-time monitoring and automation. This capability not only enhances operational efficiency but also minimizes chemical waste and reduces costs. As industries continue to emphasize sustainability and safety, the role of chemical dosing pumps becomes increasingly vital, ensuring that chemicals are utilized effectively while adhering to stringent environmental guidelines.

What is a Chemical Dosing Pump and How Does it Work for Your Needs

| Feature | Description | Applications | Flow Rate | Power Supply |

|---|---|---|---|---|

| Type | Positive Displacement | Water Treatment | 0.1 - 200 L/h | 220V AC |

| Control Type | Manual and Automatic | Chemical Processing | 10 - 1000 mL/min | Solar or DC option available |

| Materials | PVC, PVDF, Stainless Steel | Agriculture | 1 - 5000 L/h | 110V AC, 220V AC |

| Maintenance | Low Maintenance | Pharmaceuticals | Variable depending on model | Battery Backup Option |

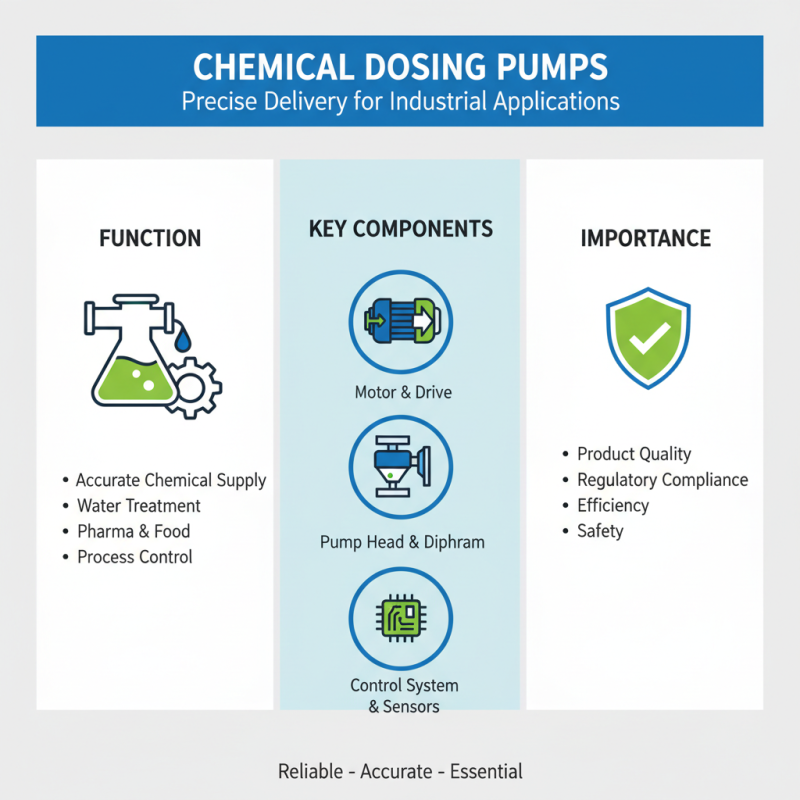

Key Components of a Chemical Dosing Pump

Chemical dosing pumps are vital components in various industrial applications, ensuring precise delivery of chemicals for processes such as water treatment, pharmaceuticals, and food production. These pumps utilize a variety of key components to achieve accurate dosing, which is critical for maintaining product quality and compliance with environmental regulations.

The primary components of a chemical dosing pump include the pump head, motor, control system, and valves. The pump head is where the chemical is drawn in and expelled, often featuring diaphragm or peristaltic designs to handle different chemical viscosities. Motors drive the pump's mechanism, with advanced models utilizing variable frequency drives for precise flow control. Control systems, often integrated with sensors, allow for real-time monitoring and adjustments, enabling operators to maintain the desired dosing rates. According to industry reports, advancements in these technologies have led to efficiency improvements of up to 25% in chemical dosing operations, reducing waste and ensuring more sustainable practices.

Valves play a crucial role in preventing backflow and ensuring that the chemical is delivered only when required. The use of proper valve types can enhance the reliability of the dosing process, which is essential in applications where consistent concentrations are necessary. As reported by market analysis firms, the global chemical dosing pump market is projected to grow significantly, driven by increasing regulatory requirements for chemical handling and a rise in industrial automation, emphasizing the importance of these key components in optimizing operational efficiency and safety.

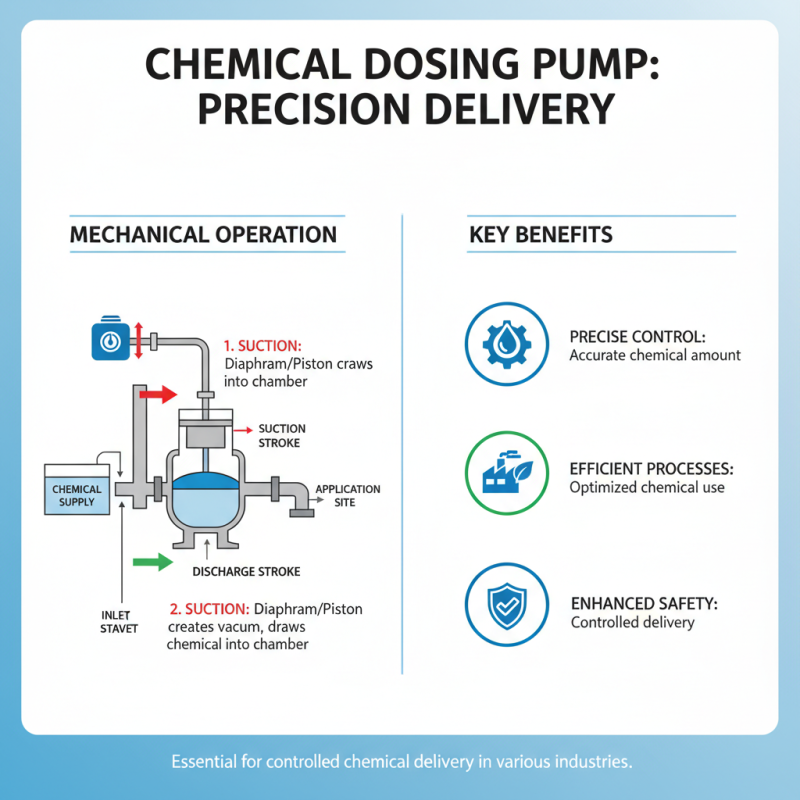

How Chemical Dosing Pumps Operate Mechanically

Chemical dosing pumps are essential devices utilized in various industries for the precise delivery of chemicals. Mechanically, these pumps operate through a combination of a motor and a diaphragm or piston, which creates a controlled and repeatable flow of liquid. The heart of a chemical dosing pump lies in its ability to generate suction during its stroke, drawing the chemical into the chamber, and then exerting pressure to deliver the fluid to the application site. This precise control ensures that the right amount of chemical is used, contributing to efficient processes and safety.

The operational mechanism consists of several key components, including a motor that powers the pump, a dosing head that contains the diaphragm or piston, and valves that manage the flow direction. When the motor operates, it activates the diaphragm or piston, altering the volume within the dosing chamber. As the chamber volume changes, it creates a vacuum that pulls fluid into the chamber, followed by the release of pressure that pushes the fluid out. This continuous cycle allows for reliable dosing, which can be adjusted based on the specific requirements of the system, enabling operators to maintain optimal chemical concentrations in various applications from water treatment to manufacturing processes.

Applications of Chemical Dosing Pumps in Various Industries

Chemical dosing pumps are vital in various industries due to their precision and reliability in delivering exact chemical quantities for specific applications. In the water treatment sector, these pumps are essential for the accurate dosage of disinfectants, coagulants, and pH adjustments, ensuring safe drinking water and effective wastewater treatment. Their ability to operate continuously and adjust flow rates based on real-time requirements makes them indispensable in maintaining optimal water quality.

In the agriculture industry, chemical dosing pumps are used for irrigation systems and nutrient delivery, enabling farmers to apply fertilizers and pesticides efficiently. This targeted application significantly enhances crop yield while minimizing environmental impact. Similarly, in the pharmaceutical and food processing sectors, these pumps ensure the consistent addition of critical ingredients and preservatives, maintaining product safety and efficacy. The versatility and adaptability of chemical dosing pumps across these diverse applications underscore their importance in modern industrial processes.

Choosing the Right Chemical Dosing Pump for Your Specific Needs

When choosing the right chemical dosing pump for your specific needs, it is crucial to consider several factors that can significantly impact performance and efficiency. First, assess the type of chemicals that will be handled. Different substances may have unique corrosive properties or viscosity that require specific materials for optimal pump performance. Additionally, understanding the required flow rate and pressure will help you select a pump that delivers the necessary dosage accurately and consistently.

Another important aspect is the operational environment. Consider whether the pump will be used indoors or outdoors, as well as the temperature and humidity conditions it will face. This can influence the choice of materials and the design of the pump. Furthermore, evaluating the ease of maintenance and availability of spare parts can contribute to long-term reliability and operational efficiency. By thoroughly analyzing these variables, you can ensure that the chemical dosing pump you select will meet your application needs effectively.

Chemical Dosing Pump Specifications

This chart illustrates various specifications for chemical dosing pumps that are critical for their operation, including flow rate in liters per hour, pressure in bars, power requirement in watts, and the number of pump types.

Related Posts

-

Understanding the Benefits of Using Above Ground Diesel Storage Tanks in Various Industries

-

How to Choose the Right Gas Transfer Pump for Your Needs

-

How to Choose the Right Centrifugal Pump for Your Industrial Needs

-

How to Choose the Right Vacuum Pump for Your Needs: A Complete Guide

-

Innovations in Fuel Storage Tanks Showcased at the 138th Canton Fair in 2025

-

How to Choose the Right Gas Pump for Your Business Needs