2026 Best Industrial Vacuum Pump Options for Your Needs?

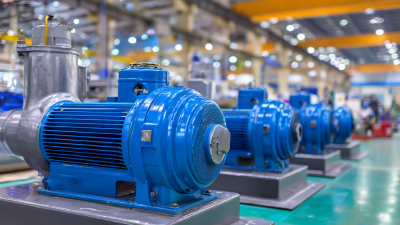

In the realm of manufacturing and industrial applications, the importance of an efficient industrial vacuum pump cannot be overstated. According to a report by MarketsandMarkets, the industrial vacuum pump market is expected to grow at a CAGR of 5.4% from 2021 to 2026. This growth reflects the rising demand for advanced solutions in various sectors, including food processing, pharmaceuticals, and semiconductor manufacturing.

Expert in the field, Dr. Emily Carter, highlights, "The right industrial vacuum pump can significantly enhance production efficiency." This statement underscores the necessity for industries to select the best vacuum pump tailored to their unique needs. With a myriad of options in the market, it is crucial to understand the specific requirements of a business before making a decision.

Choosing the appropriate industrial vacuum pump is not merely about features but addressing intricate operational challenges. While many options promise efficiency, it is vital to engage in a thorough evaluation process. Identifying the right pump involves reflecting on factors like application, energy consumption, and maintenance needs. A hasty choice could lead to operational inefficiencies and increased costs in the long run.

Overview of Industrial Vacuum Pumps and Their Applications

Industrial vacuum pumps are crucial for many sectors. They create a vacuum by removing air and other gases. This process is essential in manufacturing, packaging, and laboratory environments. A reliable vacuum pump ensures quality control and enhances productivity.

In food packaging, for example, vacuum pumps extend shelf life. They remove air to prevent spoilage. In medical industries, they maintain sterile environments. In laboratories, these pumps are used for various experiments. Their role is often understated, yet essential. Without proper pumps, processes might fail or yield inconsistent results.

Selecting the right pump is not easy. Factors like size, power, and application matter. Users often overlook the importance of maintenance. Neglecting regular checks can lead to inefficiency. Reflection on operational needs is vital for making informed decisions. The right choice enhances performance, while the wrong one can hinder progress.

Types of Industrial Vacuum Pumps: A Comprehensive Guide

Industrial vacuum pumps are essential in various sectors. They come in several types, each serving unique needs. Understanding these types can guide your decision in choosing the best fit.

Positive displacement pumps are widely used for their efficiency. These pumps operate by trapping a fixed amount of air and forcing it out. Data indicates that these pumps can achieve vacuum levels as low as 0.5 Torr. However, they may struggle with moisture-laden environments, affecting performance. Rotatory vane vacuum pumps are another popular choice. They work well in creating strong vacuum pressures, up to 29.9 inHg. Yet, their maintenance can be demanding.

On the other hand, kinetic pumps, like turbo molecular pumps, excel in high vacuum applications. They can reach ultra-low pressures, crucial for semiconductor manufacturing. Although effective, they require specialized knowledge for operation and maintenance. The selection process can feel overwhelming, but understanding the strengths and weaknesses of each type can lead to better choices. The vacuum pump market is projected to grow at a CAGR of 5.2% between 2023 and 2030. Thus, it’s vital to stay informed and continually assess your specific requirements.

Factors to Consider When Choosing an Industrial Vacuum Pump

Choosing the right industrial vacuum pump requires careful consideration. Different applications demand unique specifications. You must recognize the specific needs of your operation. Are you dealing with liquids, solids, or gases? Each type poses unique challenges.

A crucial factor is the pump's capacity. Ensure that it meets your workload requirements. If it's underpowered, efficiency drops. Over time, this can lead to equipment failure. Reliability is non-negotiable. Regular maintenance will prolong its lifespan, saving costs in the long run.

**Tips:** Always evaluate noise levels. A loud pump can disrupt the work environment. Additionally, consider the size and weight. You may need mobility for varied tasks. Don’t overlook energy efficiency. A pump that drains electricity can increase your operational costs. Remember, the right choice today affects your productivity tomorrow.

Top 2026 Industrial Vacuum Pump Models and Their Features

When selecting an industrial vacuum pump, features play a critical role. There are many models available, each with unique capabilities. Most options include rotary vane, dry scroll, and diaphragm pumps. Each type serves specific industrial applications. For instance, rotary vane pumps are highly efficient for general use. They work well in varying environments.

Dry scroll pumps are popular for their oil-free operation. They are quieter, which can reduce workplace noise. Diaphragm pumps are ideal for handling corrosive materials. They often provide robust performance. However, understanding their limitations is essential. Each model may have issues with capacity and maintenance.

Choosing the right vacuum pump also involves assessing the required power and efficiency. Consider how often the pump will be in use. Regular maintenance is crucial to ensure longevity. Some pumps may require a steep learning curve. It’s vital to weigh the pros and cons carefully before purchasing. In many cases, consultation with industry experts can help clarify needs.

2026 Best Industrial Vacuum Pump Options

This chart illustrates key features of the best industrial vacuum pumps of 2026, comparing pumping capacity, maximum vacuum, noise levels, and energy efficiency.

Maintenance Tips for Maximizing Vacuum Pump Performance

Maintaining a vacuum pump is crucial for optimal performance. Regular maintenance extends the lifespan of the equipment. According to industry reports, well-maintained vacuum pumps can last up to 50% longer than those neglected. This highlights the importance of routine checks.

One key maintenance tip is to keep the intake filters clean. Clogged filters can hinder airflow, causing the pump to work harder. A study found that dirty filters can reduce pump efficiency by 30%. Replace or clean filters according to the manufacturer's specifications. This simple action can prevent costly downtimes and maintain efficienc.

Monitor oil levels and quality regularly. Oil lubricates the pump, reducing friction and wear. Use high-quality oil to minimize contaminants. Change the oil as recommended. Contaminated oil can lead to pump failure. In fact, data shows that 40% of vacuum pump failures are due to inadequate lubrication practices. Keep a maintenance log, track your actions, and adjust as needed. Regular attention to these details will keep your vacuum pumps running smoothly.

2026 Best Industrial Vacuum Pump Options for Your Needs

| Model | Type | Max Vacuum (inHg) | Pump Rate (CFM) | Noise Level (dB) | Weight (lbs) | Maintenance Tips |

|---|---|---|---|---|---|---|

| Model A | Rotary Vane | 29.9 | 15 | 72 | 50 | Clean filters regularly |

| Model B | Diaphragm | 28.5 | 12 | 68 | 40 | Lubricate according to usage |

| Model C | Scroll | 29.0 | 20 | 65 | 55 | Inspect seals frequently |

| Model D | Liquid Ring | 27.5 | 25 | 70 | 65 | Check water levels regularly |

| Model E | Piston | 29.5 | 18 | 75 | 58 | Replace oil as per schedule |

Related Posts

-

Exploring Vacuum Pump Innovations at the 138th Canton Fair 2025: Trends and Data Insights

-

Understanding the Different Types of Vacuum Pumps and Their Applications

-

How to Choose the Right Centrifugal Pump for Your Industrial Needs

-

Unlocking Efficiency and Cost Savings with Advanced Fuel Transfer Pump Solutions

-

Top 2026 Gas Pump Innovations You Need to Know?

-

How to Choose the Best Diesel Transfer Tank with Pump for Your Needs in 2025