Best Dosing Pump for Accurate Chemical Delivery?

Choosing the best dosing pump is crucial for precise chemical delivery. Accurate doses can prevent costly mistakes. A reliable dosing pump ensures that chemical concentrations remain consistent.

Many industries use dosing pumps, from agriculture to water treatment. Each application requires specific features. Some dosing pumps offer manual control, while others use advanced automation. A simple design may seem sufficient, but it may lack the precision needed.

Selecting a dosing pump involves assessing various factors. Users must consider flow rate and pressure. Ultimately, the right pump provides not just functionality, but efficiency. However, determining which dosing pump meets specific needs can be challenging. Users often face uncertainty, and it is essential to reflect on these choices.

Overview of Dosing Pumps and Their Applications

Dosing pumps play a crucial role in various industries, ensuring precise chemical delivery. They are widely used in water treatment, food processing, and pharmaceuticals. According to a recent market report, the global dosing pump market is projected to reach $8.5 billion by 2027, highlighting their importance in maintaining quality and safety.

In water treatment, dosing pumps deliver chemicals like chlorine and flocculants to purify water. These pumps can accurately dispense small amounts, reducing waste and improving efficiency. A report from a leading industry analyst indicates that improper dosing can lead to suboptimal water quality. This is why the accuracy of dosing pumps is vital.

However, not all dosing pumps are equal. Many users overlook regular maintenance. Neglecting to check calibration can result in inaccuracies. A survey showed that nearly 25% of operators experience issues due to maintenance lapses. Thus, understanding the specific needs of an application and ensuring proper upkeep is key to performance.

Best Dosing Pump for Accurate Chemical Delivery

Key Features to Look for in an Accurate Dosing Pump

When selecting a dosing pump for chemical delivery, accuracy is paramount. A reliable dosing pump should have precise flow rate control. According to recent industry data, the accuracy of chemical dosing can reduce waste by up to 30%. This means better resource management and cost efficiency for operations.

Key features to evaluate include the pump's calibration range and adjustable flow settings. A pump that allows for fine-tuning its output can significantly improve application accuracy. In addition, materials should be resistant to the chemicals being handled. This can prevent degradation and lead to longer-lasting equipment.

Monitoring capabilities are also crucial. A pump that provides real-time feedback helps operators adjust dosing rates as needed. Many reports highlight that integrating smart technology can enhance user control. However, these systems can sometimes lead to over-reliance on technology rather than manual checks. Investing in training for operators could mitigate this risk. Ultimately, understanding these features ensures a more accurate chemical delivery process.

Best Dosing Pump for Accurate Chemical Delivery? - Key Features to Look for in an Accurate Dosing Pump

| Feature | Description | Importance |

|---|---|---|

| Flow Rate Adjustment | Ability to easily adjust the flow rate to meet specific dosing needs. | High |

| Accuracy | Precise delivery of chemicals with minimal deviation from the set point. | Critical |

| Material Compatibility | Constructed from materials that resist corrosion and degradation depending on the chemicals used. | High |

| Control Options | Multiple control methods, such as manual, digital, or remote, for flexibility in operation. | Medium |

| Safety Features | Includes features like overpressure protection and alarms for fault detection. | High |

| Easy Maintenance | Design that allows for easy access and routine maintenance to ensure reliability. | Medium |

Types of Dosing Pumps: Pros and Cons Comparison

Dosing pumps are crucial for precise chemical delivery across various industries. Understanding their types and associated pros and cons helps users select the best option. Positive displacement pumps are efficient and accurate. They deliver a set volume of chemical with every stroke. However, they require frequent maintenance, which can lead to downtime.

On the other hand, diaphragm pumps offer versatility and reliability. They can handle corrosive chemicals with minimal risk of leaks. A report by the Chemical Engineering magazine indicated that diaphragm pumps could achieve flow rates of 0.1 to 10 GPH, making them ideal for smaller applications. Yet, they are often less accurate than positive displacement models for continuous dosing.

Peristaltic pumps, another option, use rollers to compress tubing. This design allows for gentle handling of shear-sensitive chemicals. According to industry experts, these pumps are less prone to contamination. However, their accuracy can diminish over time with tubing wear. This necessitates regular tubing replacement, which adds to long-term costs. Users must weigh these factors carefully when choosing a dosing pump.

Factors Affecting Chemical Delivery Accuracy

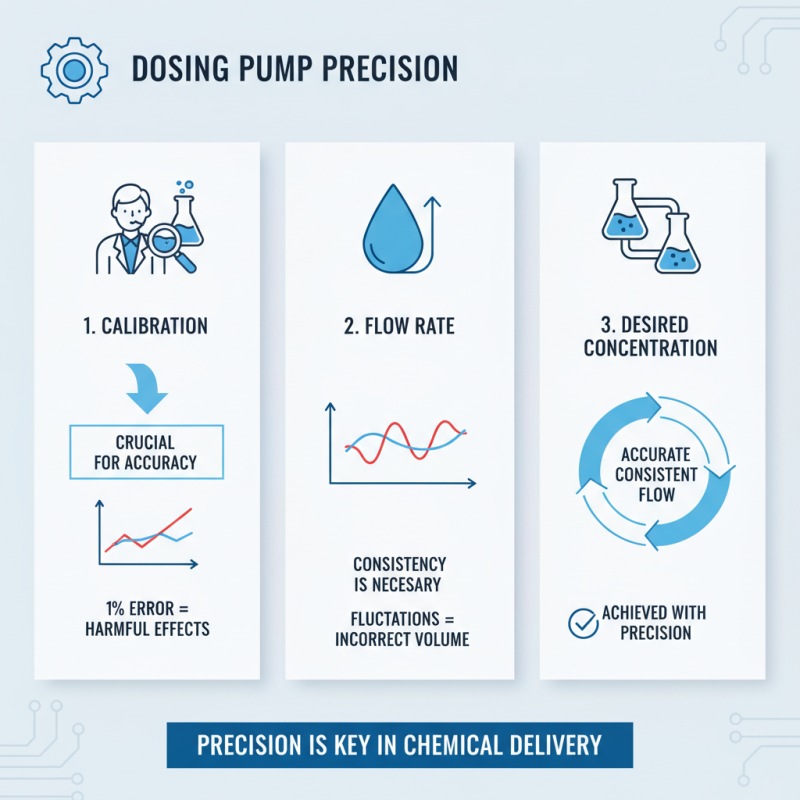

When selecting a dosing pump, precision is key. Various factors influence the accuracy of chemical delivery. Calibration is crucial. An improperly calibrated pump can lead to significant errors. According to industry reports, a deviation of just 1% can result in harmful effects in some applications. Flow rate is another significant element. If the flow rate fluctuates, it will affect the volume delivered. Consistency in flow is necessary for achieving the desired concentration.

Another factor to consider is the viscosity of the chemicals being pumped. High-viscosity fluids can lead to inaccurate dosing due to resistance in the lines. As outlined in recent studies, pumps can show a performance drop of up to 30% when handling thicker substances. This inconsistency can have serious implications. Regular maintenance is essential to keep pumps functioning accurately. Over time, wear and tear can alter delivery rates, making routine checks necessary.

Lastly, the type of materials used in pump construction plays a role. Certain materials can corrode or degrade over time, affecting accuracy. A material that suits one chemical may not work well for another. This variability can be overlooked, leading to subpar performance. Continuous monitoring and adjustment become vital in maintaining optimal dosing accuracy, emphasizing the need for comprehensive understanding.

Maintenance Best Practices for Dosing Pumps

Dosing pumps play a crucial role in precise chemical delivery across industries. However, without proper maintenance, these pumps can falter. Periodic checks are essential. Studies show that over 30% of pump failures result from inadequate maintenance. Understanding common issues can help.

Regular inspections should focus on seals and valves. Worn seals can lead to leaks, impacting accuracy. A leak, even small, might mean significant losses. Workers often overlook valve conditions, but they must be clean and functioning well. Proper lubrication can extend pump life, yet many neglect this simple practice.

Another vital aspect is monitoring flow rates. An annual calibration ensures dosing accuracy. Inconsistent flow can mean variable chemical delivery, resulting in inconsistent product quality. A 2021 industry report indicated that 25% of dosing inaccuracies resulted from flow irregularities. Operators should track flow rates actively, adjusting when needed, to ensure systems run smoothly. Regular maintenance and vigilant monitoring are keys to maximizing pump efficiency and reliability.

Related Posts

-

What is a Chemical Dosing Pump and How Does it Work for Your Needs

-

Ultimate Diesel Transfer Pump Tips for Efficient Fuel Handling?

-

How to Choose the Right Gas Transfer Pump for Your Industrial Needs

-

Top Strategies for Enhancing Efficiency with Metering Pumps

-

Top 10 Tips for Choosing the Right Diesel Tank with Pump for Your Needs

-

Understanding the Different Types of Vacuum Pumps and Their Applications