Exploring the Benefits of Air Operated Diaphragm Pumps: A Comprehensive Guide for Industrial Applications

In the realm of industrial applications, efficiency and reliability are paramount, and one piece of equipment that consistently delivers on these fronts is the air operated diaphragm pump. This innovative pumping solution is engineered to handle a wide range of substances, from corrosive chemicals to viscous slurries, making it an invaluable asset across various sectors. As industries strive to optimize their processes, understanding the benefits of air operated diaphragm pumps becomes crucial. This comprehensive guide delves into the numerous advantages these pumps offer, including their operational versatility, low maintenance requirements, and ability to function in hazardous environments. By exploring key features and real-world applications, this guide serves as an essential resource for professionals seeking to enhance their operational efficiency while ensuring safety and reliability in their industrial processes.

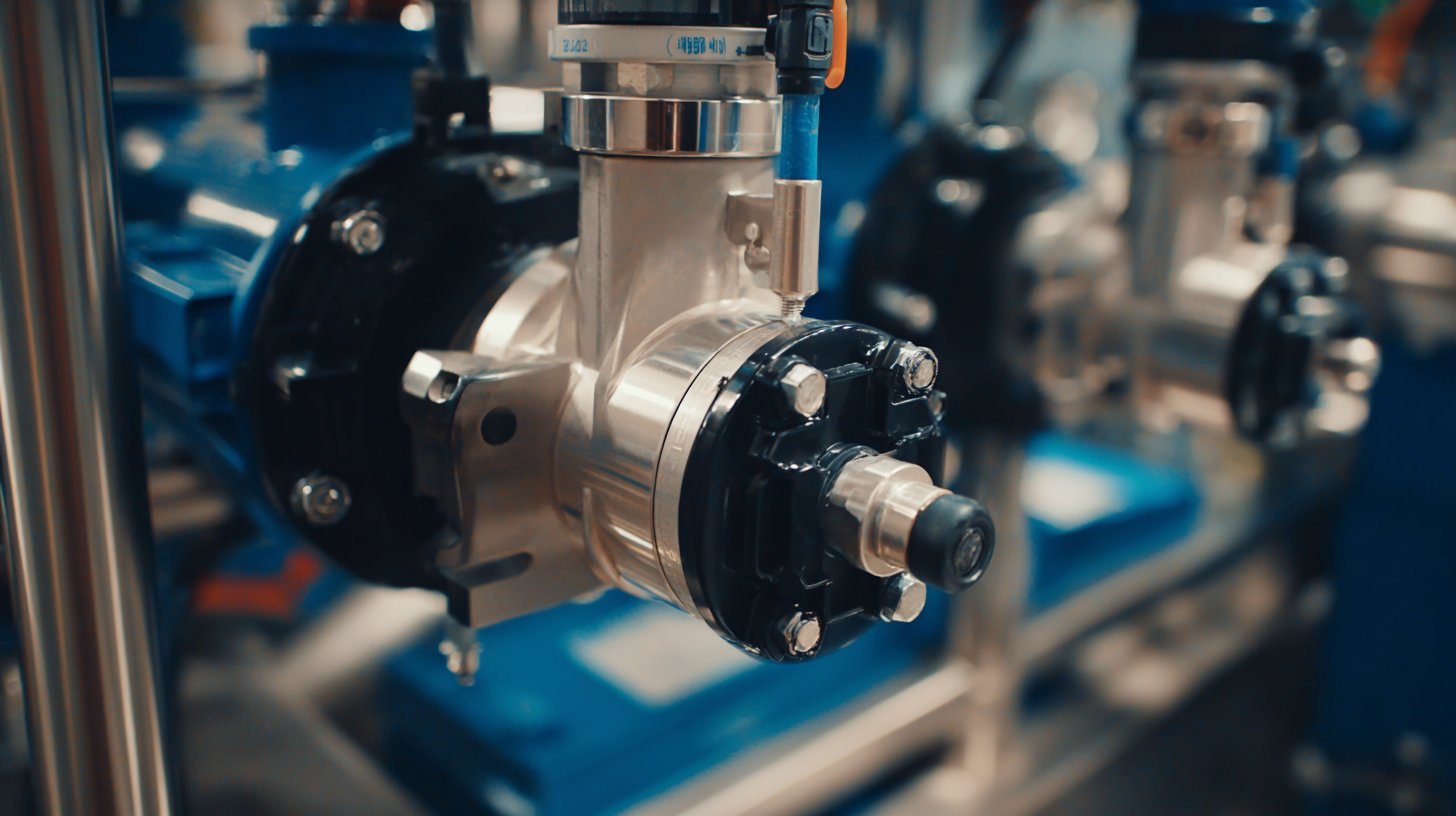

Understanding the Mechanism: How Air Operated Diaphragm Pumps Work in Industrial Applications

Air Operated Diaphragm Pumps (AODD pumps) are a popular choice in industrial applications due to their efficient, reliable, and versatile operation. Understanding their mechanism is crucial for maximizing their benefits. AODD pumps function by converting compressed air into mechanical energy, which drives the diaphragm back and forth. This movement creates a suction effect that draws fluid into the pump, while simultaneously forcing fluid out through the discharge port. According to a report by Grand View Research, the global diaphragm pump market is expected to reach $3.65 billion by 2025, underscoring the growing reliance on this technology in various industries.

One key advantage of AODD pumps is their ability to handle a wide range of viscous and abrasive fluids, making them ideal for sectors such as chemical processing and food production. Their design also allows for dry running without damage, which is critical in industries that may experience interruptions in fluid flow. A study published by Research and Markets indicates that the demand for AODD pumps in the chemical and pharmaceutical sectors is projected to grow by 7.6% annually through 2023, highlighting the pump's effectiveness in meeting the sector's stringent requirements. This operational flexibility combined with their robust design makes AODD pumps an essential asset for industrial applications.

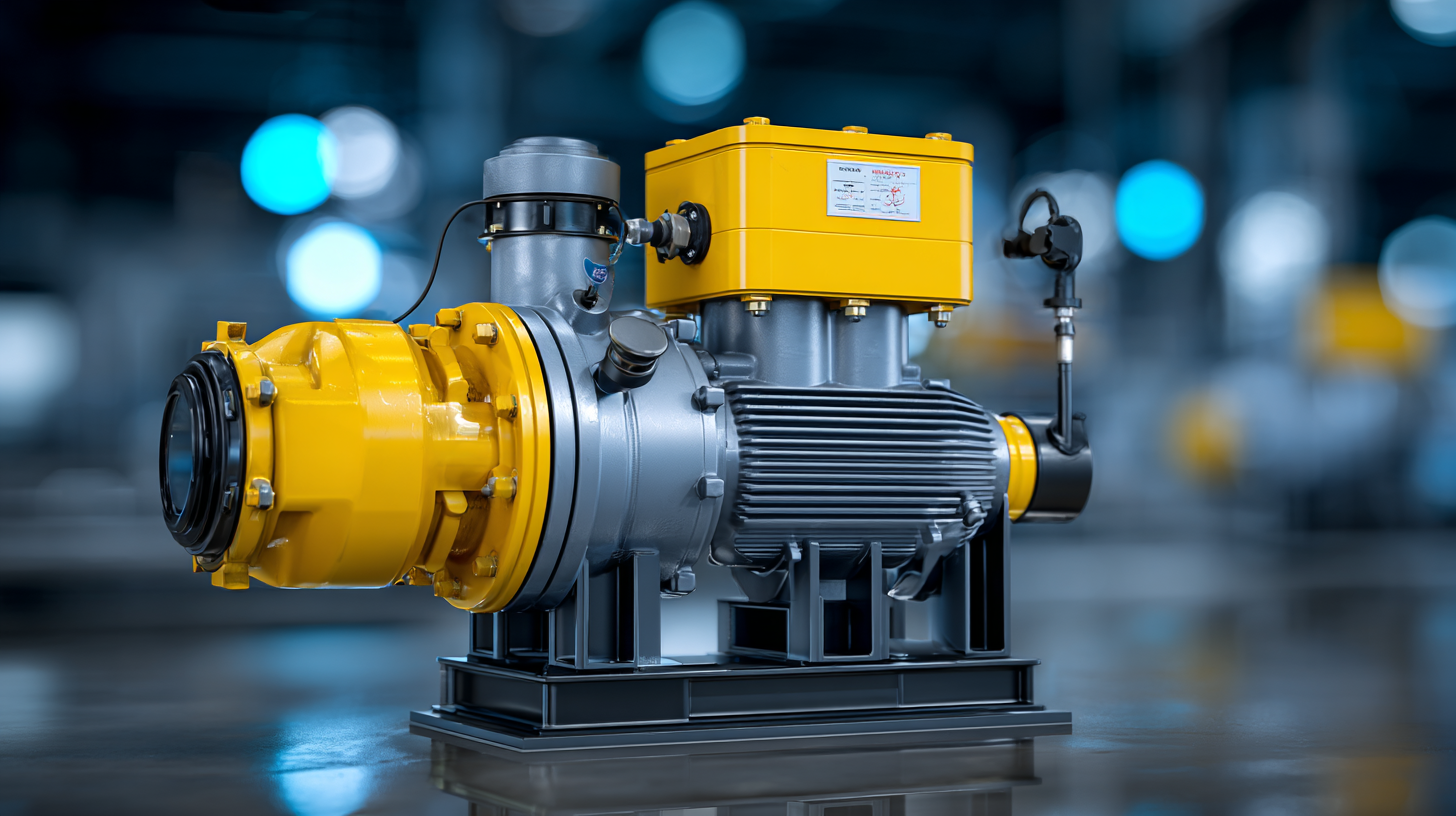

Key Benefits: Efficiency and Cost-Effectiveness of AOD Pumps Compared to Other Pump Types

Air Operated Diaphragm (AOD) pumps have gained popularity in industrial applications due to their efficiency and cost-effectiveness. One of the main advantages of AOD pumps is their ability to handle a wide range of fluids, including corrosive and viscous substances. This versatility allows industries to reduce their inventory of different pump types, ultimately leading to cost savings. Additionally, AOD pumps operate using a simple pneumatic mechanism, which reduces the need for complex electrical systems and minimizes maintenance costs over time.

In comparison to traditional pumps like centrifugal or positive displacement pumps, AOD pumps often provide superior efficiency. They require less energy to operate, as they utilize compressed air to create the necessary pumping action. This energy efficiency not only lowers operational costs but also contributes to a reduced carbon footprint, aligning with modern sustainability goals in industrial practices. Furthermore, the sturdy construction of AOD pumps ensures durability and a long service life, making them a reliable choice for continuous operations, thereby enhancing overall productivity.

Efficiency and Cost-Effectiveness of Air Operated Diaphragm Pumps (AOD Pumps)

This chart compares the efficiency and cost-effectiveness of Air Operated Diaphragm Pumps (AOD Pumps) with other common pump types such as Centrifugal Pumps and Positive Displacement Pumps. The data represents the average efficiency in terms of operational cost savings and energy consumption across various industrial applications.

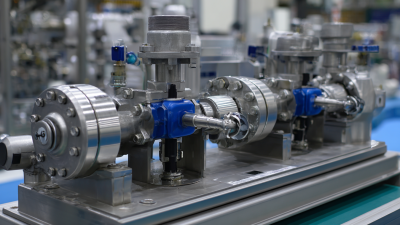

Industry Data Insights: Performance Metrics and Reliability of AOD Pumps in Various Sectors

Air Operated Diaphragm (AOD) pumps are integral to various industrial applications due to their reliability and efficiency. In North America, the utility pump market is expanding, with AOD pumps playing a crucial role across segments like transfer, submersible, and dewatering pumps. Their versatility allows for excellent performance metrics, including flow rates and pressure control, making them suitable for sectors such as wastewater management and chemical processing.

Air Operated Diaphragm (AOD) pumps are integral to various industrial applications due to their reliability and efficiency. In North America, the utility pump market is expanding, with AOD pumps playing a crucial role across segments like transfer, submersible, and dewatering pumps. Their versatility allows for excellent performance metrics, including flow rates and pressure control, making them suitable for sectors such as wastewater management and chemical processing.

When considering AOD pumps for industrial applications, it's essential to analyze performance metrics. An in-depth look at industry data reveals that these pumps exhibit remarkable reliability even under fluctuating conditions. For instance, their ability to handle viscous fluids without losing efficiency is a key advantage noted across various applications.

Tips: Regular maintenance of AOD pumps can significantly enhance their lifespan and operational efficiency. Additionally, monitoring the pump's performance with pressure transmitters can provide valuable insights into functionality, enabling timely interventions that prevent downtime. Lastly, choosing the right product type—be it for dewatering, transfer, or other specific applications—can optimize processes and ensure consistent outputs.

Maintenance Best Practices: Prolonging the Lifespan of Air Operated Diaphragm Pumps in Operations

Maintaining air-operated diaphragm pumps (AODDs) is crucial for maximizing their efficiency and longevity in industrial applications. According to a report by the Hydraulic Institute, proper maintenance can extend the lifespan of diaphragm pumps by up to 25%, significantly reducing operational costs. Regular inspections and routine servicing are essential; industries should implement a preventive maintenance schedule that includes checking for air leaks, ensuring that diaphragms are not worn or damaged, and monitoring the condition of the check valves.

Additionally, selecting the right materials for specific applications can enhance pump durability. A study from the American Society of Mechanical Engineers indicates that using appropriate diaphragm materials, such as Santoprene or PTFE, can improve resistance to chemicals and wear, leading to fewer failures. Furthermore, ensuring that the pump is not run dry and is used within its specified flow rate and pressure boundaries can prevent unnecessary strain on its components. By adhering to these maintenance best practices, facilities can not only prolong the service life of air-operated diaphragm pumps but also optimize their performance in demanding industrial settings.

Safety Features: How AOD Pumps Enhance Workplace Safety in Hazardous Environments

Air Operated Diaphragm (AOD) pumps are increasingly recognized for their pivotal role in enhancing workplace safety, especially in hazardous environments. The design of AOD pumps inherently incorporates several safety features that mitigate risks associated with handling volatile substances. For instance, these pumps utilize air pressure as their driving force, eliminating the need for electrical components. This key feature significantly reduces the risk of sparks, making them ideal for combustible and flammable liquids.

Moreover, AOD pumps are constructed from materials that resist corrosion and are compatible with a variety of chemicals, which further ensures safe operation in demanding industrial settings. Their simple construction allows for easy maintenance and quick replacement of parts without requiring specialized tools, reducing the risk of accidental leaks during servicing. Additionally, many AOD pumps are equipped with built-in pressure relief valves that prevent over-pressurization, safeguarding both the equipment and the operators from potential hazards. Through these innovative safety features, AOD pumps not only enhance operational efficiency but also create a safer working environment in industries that deal with hazardous materials.

Related Posts

-

How to Select the Right Diaphragm Pump for Your Industrial Needs

-

How to Choose the Right Air Operated Diaphragm Pump for Your Applications

-

The Essential Guide to Choosing the Right Air Diaphragm Pump for Your Application Needs

-

How to Choose the Right Gas Transfer Pump for Your Industrial Needs

-

How to Choose the Right Double Diaphragm Pump for Your Application

-

Unlocking Efficiency: The Advantages of Advanced Fuel Storage Tanks for Your Business