What is an Air Operated Diaphragm Pump and How Does It Work?

Air operated diaphragm pumps (AODD pumps) are becoming increasingly essential in various industrial applications due to their versatility and reliability. As noted by John Smith, a prominent expert in fluid dynamics, “The air operated diaphragm pump is a game changer for industries needing safe and efficient fluid transfer.” This statement underscores the crucial role these pumps play in maintaining operational efficiency while ensuring the safety of both workers and the environment.

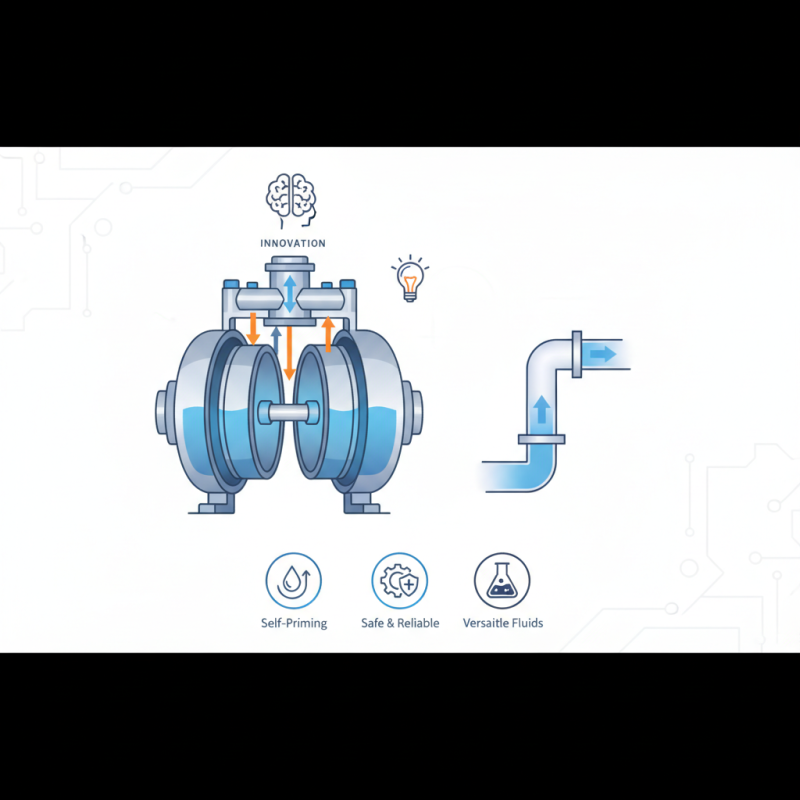

AODD pumps utilize a simple yet effective mechanism, relying on compressed air to create a suction that draws fluid into the pump. This innovative design not only minimizes the risk of leaks but also allows for the handling of a diverse range of liquids, including corrosive substances and viscous materials. The ability to self-prime and run dry makes air operated diaphragm pumps indispensable in scenarios where traditional pump systems might fail.

Overall, understanding the function and advantages of air operated diaphragm pumps is vital for professionals seeking reliable solutions in fluid management. As industries continuously strive for enhanced performance and safety, the significance of AODD pumps cannot be overstated, making them a focal point for ongoing innovation and development in the field.

What is an Air Operated Diaphragm Pump?

An air operated diaphragm pump (AODD pump) is a type of positive displacement pump that utilizes compressed air to drive its operation. It consists primarily of two diaphragms that alternately move to create a pumping action. When air pressure is applied to one side of a diaphragm, it flexes, drawing fluid into the pump through an inlet valve while simultaneously forcing fluid out through an outlet valve as the opposite diaphragm returns to its original position. This back-and-forth movement is repeated in a continuous cycle, allowing for consistent fluid transfer.

The design of air operated diaphragm pumps allows them to handle a wide variety of fluids, including slurries, chemicals, and viscous materials. Their simplicity and robust construction make them highly versatile and suitable for use in various industries, such as wastewater management, food processing, and pharmaceuticals. Moreover, since they are powered by compressed air, these pumps can operate in hazardous environments without the risk of electric sparks, further enhancing their safety and adaptability in demanding applications.

Key Components of Air Operated Diaphragm Pumps

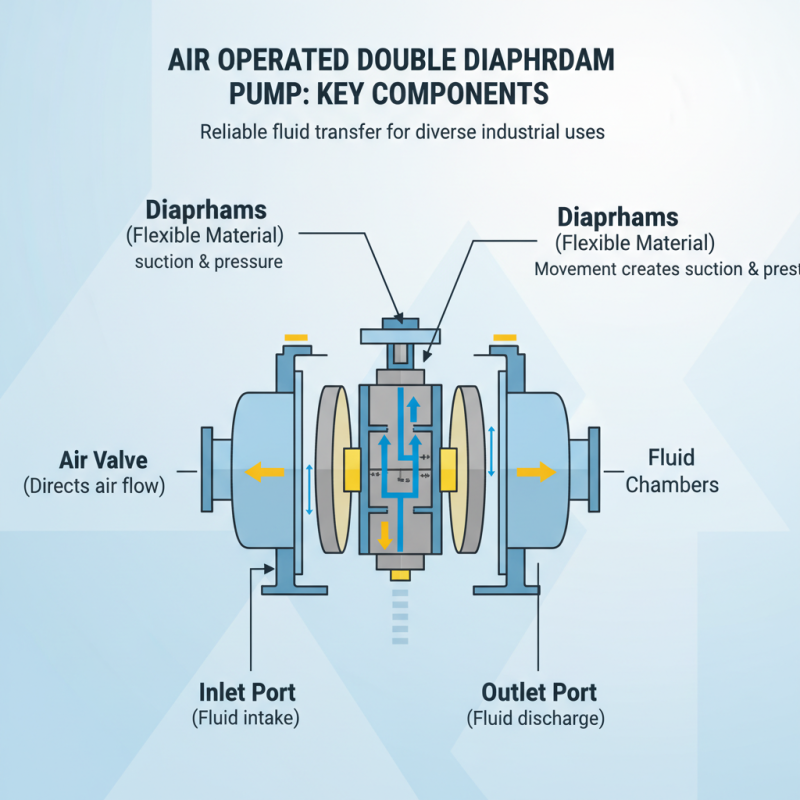

Air Operated Diaphragm Pumps (AODDs) are innovative devices commonly used for transferring fluids in various industrial applications. The key components that make up these pumps are critical to their operation and efficiency. At the heart of every AODD is the diaphragm itself, usually made from flexible materials that can withstand various chemicals. The diaphragm's movement creates suction and pressure that allows for efficient fluid transfer.

Another essential component is the air chamber, which is responsible for the diaphragm's reciprocating motion. When compressed air enters this chamber, it pushes the diaphragm in one direction, causing fluid to be drawn into the pump chamber. As the air pressure alternates, the diaphragm shifts back, expelling the fluid through the discharge port. Additionally, AODDs include check valves that ensure unidirectional flow, preventing backflow and enhancing system reliability. These components work in concert to intelligently manage the flow of diverse liquids, making AODDs versatile solutions in numerous settings.

How Air Operated Diaphragm Pumps Function

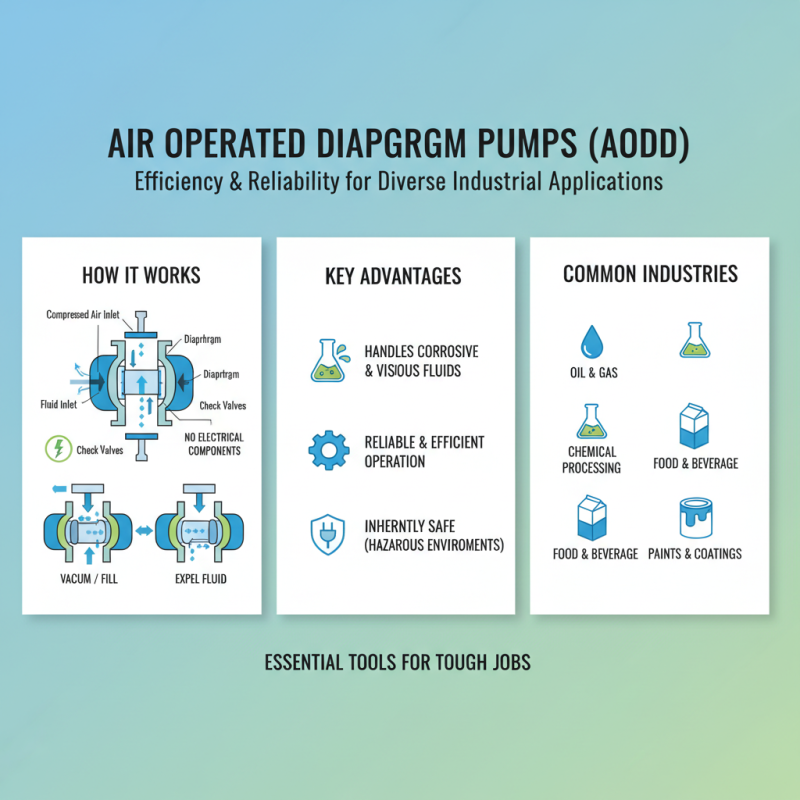

Air Operated Diaphragm Pumps (AODDs) are essential tools in various industries, known for their efficiency and reliability. The core function of AODDs revolves around their unique design that uses compressed air to create a pumping action. Unlike traditional pumps, AODDs utilize a diaphragm that is flexed by the air pressure, producing a vacuum that draws fluid into the chamber. When the diaphragm returns to its original position, fluid is expelled from the pump. This mechanism allows for the handling of a variety of fluids, including corrosive and viscous substances, without any electrical components, making AODDs suitable for environments where electrical safety is a concern.

According to a recent industry report, the global air-operated diaphragm pump market is expected to reach USD 5.1 billion by 2027, driven by increasing demand in sectors such as chemical processing and water and wastewater management. The versatility of AODDs allows them to work in a range of applications, from transferring paints and coatings to moving slurries in mining operations. Additionally, their ability to self-prime and run dry without damage enhances their operational reliability. This is particularly beneficial in applications where fluid availability may be intermittent, making AODDs a preferred choice for many industrial processes, as highlighted by recent market analysis.

Advantages of Using Air Operated Diaphragm Pumps

Air operated diaphragm pumps (AODDs) are increasingly popular in various industries due to their unique advantages over other pumping technologies. One of the primary benefits of using AODDs is their versatility. They can handle a wide range of fluids, including corrosive and viscous materials, without the need for complex modifications. Their ability to self-prime and run dry makes them ideal for applications where fluid supply is inconsistent or where occasional emptying is necessary.

Another significant advantage of AODDs is their reliability and maintenance ease. With fewer moving parts compared to traditional pumps, these diaphragm pumps require less frequent maintenance, reducing downtime and operational costs. The air-powered mechanism also eliminates the risk of electrical hazards, making AODDs a safer choice in flammable or explosive environments. Furthermore, the ability to adjust flow rates by simply changing the air pressure adds a level of control that is particularly beneficial in processes where precise fluid movement is essential. This combination of safety, reliability, and versatility makes air operated diaphragm pumps a preferred choice across various applications, from chemical processing to food and beverage industries.

What is an Air Operated Diaphragm Pump and How Does It Work? - Advantages of Using Air Operated Diaphragm Pumps

| Feature | Description | Advantages |

|---|---|---|

| Mechanism | Uses compressed air to operate diaphragm | No electricity required, safe for hazardous areas |

| Materials | Can be manufactured from various materials like plastic or metal | Versatile for different fluid types, including corrosive substances |

| Maintenance | Relatively low maintenance required | Cost-effective over time |

| Flow Rate | Variable flow rates available depending on size | Flexible for various applications |

| Portability | Can be easily moved and relocated | Ideal for temporary installations and job sites |

| Self-priming | Capable of self-priming and can run dry | Increased reliability for various applications |

Common Applications of Air Operated Diaphragm Pumps

Air Operated Diaphragm Pumps (AOD pumps) are versatile devices used across various industries due to their efficiency and reliability. One of the most common applications of these pumps is in the transfer of hazardous and abrasive fluids. Their ability to handle slurries, viscous liquids, and even solids makes them ideal for mining and construction sectors where such materials are prevalent. Furthermore, the absence of electrical components allows for safe operation in explosive environments, enhancing their applicability in the oil and gas industry.

In addition to hazardous fluid transfer, AOD pumps are frequently employed in wastewater treatment facilities. They are effective in moving effluents and activated sludge without the risk of contamination, thanks to their sealing design. This pump type is also advantageous in food processing, as it can handle sanitary applications while maintaining the integrity of the product, making it suitable for transferring various food products and ingredients. The flexibility and adaptability of air operated diaphragm pumps ensure they continue to be essential tools in diverse industrial settings, promoting efficiency and safety.

Related Posts

-

10 Essential Tips for Choosing the Right Gear Pump for Your Applications

-

How to Choose the Right Diesel Tank for Your Business Needs Based on Industry Standards

-

How to Choose the Right Suction Pump for Your Industrial Needs

-

Understanding the Different Types of Vacuum Pumps and Their Applications

-

Understanding the Benefits of Using Above Ground Diesel Storage Tanks in Various Industries

-

How to Choose the Right Gas Transfer Pump for Your Industrial Needs