Unleashing the Power of Air Diaphragm Pumps: How They Revolutionize Fluid Handling in Various Industries

In the rapidly evolving landscape of industrial fluid management, the air diaphragm pump stands out as a transformative innovation, revolutionizing how fluids are handled across various sectors. These pumps leverage a unique mechanism that combines the reliability of air pressure with versatile fluid transfer capabilities, making them an optimal choice for a myriad of applications, from chemical processing to food and beverage production. As industries continue to demand more efficient, safer, and environmentally friendly solutions, air diaphragm pumps are emerging as game-changers, offering enhanced performance and adaptability. This article delves into the myriad benefits of adopting air diaphragm pumps, exploring their impact on operational efficiency, maintenance reduction, and sustainability, while highlighting their best applications across diverse industries. By harnessing the power of air diaphragm pumps, businesses can not only streamline their fluid handling processes but also achieve significant competitive advantages in today’s dynamic market.

Understanding Air Diaphragm Pumps: Principles of Operation and Design

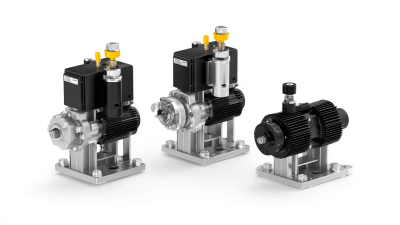

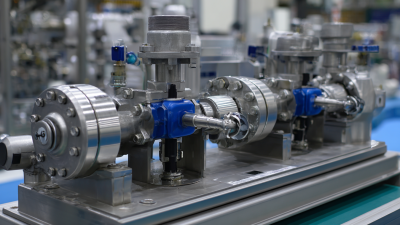

Air diaphragm pumps are a remarkable innovation in fluid handling, operating on a simple yet effective principle. These pumps utilize compressed air to create a diaphragm movement, which alternates between suction and discharge cycles. The unique design consists of two diaphragms that work in tandem—one draws fluid in while the other expels it. This mechanism allows air diaphragm pumps to handle a wide range of liquids, including corrosive and viscous fluids, making them indispensable in industries such as chemical processing, food and beverage, and wastewater treatment.

**Tip:** When selecting an air diaphragm pump, consider the material compatibility with the fluid being handled. Using pumps made from materials resistant to chemical corrosion can significantly extend the lifespan of the pump and enhance operational efficiency.

Furthermore, air diaphragm pumps are self-priming and can run dry without damage, which is a considerable advantage in many applications. Their versatility is also exemplified in their ability to transport slurries and shear-sensitive fluids without causing degradation. This adaptability not only streamlines processes but also reduces the need for multiple types of pumps within a facility.

**Tip:** Regular maintenance, including diaphragm inspection and air leak checks, is crucial to ensure optimal performance and longevity of air diaphragm pumps.

Unleashing the Power of Air Diaphragm Pumps: How They Revolutionize Fluid Handling in Various Industries

| Feature | Description | Industry Applications | Benefits |

|---|---|---|---|

| Structure | Composed of two diaphragms that create suction and pressure. | Chemical processing, food and beverage, waste water management | Safe for corrosive fluids, low maintenance |

| Operation | Uses compressed air to operate the diaphragms. | Pharmaceutical, oil and gas, mining | Handles thick and viscous fluids easily |

| Efficiency | High efficiency with low energy consumption. | Agriculture, construction, automotive | Cost-effective solution for fluid transfer |

| Control | Easy to control flow rate and pressure. | Environmental services, electronics, textiles | Precision in applications requiring careful fluid handling |

Advantages of Air Diaphragm Pumps in Fluid Handling Applications

Air diaphragm pumps have emerged as a versatile solution for fluid handling across various industries, providing significant advantages that enhance operational efficiency. One of the primary benefits of these pumps is their ability to handle a wide range of fluids, including corrosive chemicals, slurries, and viscous substances, without the risk of damaging the pump. This adaptability makes them ideal for industries such as chemical processing, pharmaceuticals, and food production, where the integrity of the fluid is critical.

Another notable advantage of air diaphragm pumps is their self-priming capability and ability to run dry without sustaining damage. This feature reduces the need for additional equipment and ensures reliable operation even in challenging environments. Additionally, the design of air diaphragm pumps allows for easy maintenance and quick replacement of parts, minimizing downtime and reducing operational costs. Overall, their reliability and efficient fluid handling make air diaphragm pumps a revolutionary choice for various industrial applications.

Choosing the Right Air Diaphragm Pump for Your Industry Needs

Choosing the right air diaphragm pump for your industry needs is crucial for optimizing fluid handling processes. Different industries, such as food and beverage, pharmaceuticals, and wastewater management, require pumps that cater specifically to their operational demands. Factors such as the type of fluid, viscosity, flow rate, and chemical compatibility should guide your selection. For instance, food-safe materials and certifications are vital for the food industry, while chemical resistance is essential in the pharmaceutical sector.

Tip: Always consider the operational environment when selecting a pump. For applications involving corrosive substances, a diaphragm pump constructed from chemically resistant materials will enhance longevity and reliability.

Furthermore, understanding the maintenance requirements of each pump type can prevent costly downtimes. Air diaphragm pumps generally offer ease of maintenance, but it's important to assess the service intervals and availability of replacement parts.

Tip: Implement a regular maintenance schedule to prolong the life of your pump and ensure optimal performance, particularly in high-use applications. Regular checks can also help identify potential issues before they escalate, saving time and money in the long run.

Maintenance Tips for Optimal Performance of Air Diaphragm Pumps

Air diaphragm pumps are renowned for their versatility and efficiency across various industries, but to ensure optimal performance, regular maintenance is crucial. One essential tip is to routinely check and replace worn-out diaphragms and seals. These components are subject to wear due to continuous flexing and can lead to leaks or reduced efficiency if not addressed. Integrating a preventive maintenance schedule can significantly help in mitigating unexpected downtime and extend the pump's lifespan.

Additionally, regular inspections of the air supply system are vital. Ensuring that the air compressor is functioning properly and that there are no blockages or leaks in the air lines will contribute to smoother operations. It’s also beneficial to clean the pump frequently to prevent any buildup of debris that could impair performance. By adhering to these maintenance practices, operators can enhance the reliability of air diaphragm pumps and fully harness their capability to handle various fluids effectively.

Real-World Applications: Success Stories in Various Industries Using Diaphragm Pumps

Air diaphragm pumps have proven to be a game-changer in fluid handling across diverse industries, with numerous real-world applications showcasing their effectiveness. In the chemical manufacturing sector, these pumps enable safe and efficient transfer of corrosive and viscous liquids. A notable example is a leading chemical processing company that successfully utilized air diaphragm pumps to minimize downtime and maintenance costs, resulting in increased productivity and enhanced safety for their workers.

Similarly, in the food and beverage industry, air diaphragm pumps are essential for handling sensitive products like sauces and juices without compromising quality. A brewing company implemented these pumps to streamline their beer transfer process, drastically reducing contamination risks and ensuring precise flow rates. This transition not only improved their operational efficiency but also enhanced the overall flavor profile of their final products by maintaining consistency throughout the brewing process. Such success stories illustrate how air diaphragm pumps can adapt to meet the unique challenges of different industries, driving innovation and efficiency in fluid management.

Unleashing the Power of Air Diaphragm Pumps in Various Industries

This bar chart illustrates the distribution of air diaphragm pump usage across various industries, showcasing the versatility and success of these pumps in fluid handling applications.

Related Posts

-

How to Select the Right Diaphragm Pump for Your Industrial Needs

-

The Essential Guide to Choosing the Right Air Diaphragm Pump for Your Application Needs

-

How to Choose the Right Air Operated Diaphragm Pump for Your Applications

-

Exploring the Benefits of Air Operated Diaphragm Pumps: A Comprehensive Guide for Industrial Applications

-

How to Choose the Right Gas Transfer Pump for Your Industrial Needs

-

Everything You Need to Know About Transfer Tank Pumps: Your Ultimate Guide to Safe Fuel Handling